M370 • WOEJ-MM • WO0804..

인서트 • 중삭 • WOEJ-MM

제품 번호4113915

ISO 카탈로그 IDWOEJ080412SRMMANSI 카탈로그 IDWOEJ080412SRMM

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 제품 번호 | 4113915 |

| ISO 카탈로그 ID | WOEJ080412SRMM |

| ANSI 카탈로그 ID | WOEJ080412SRMM |

| Grade | TN6540 |

| Cutting Edges per Insert | 6 |

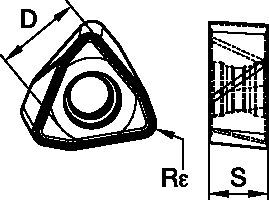

| [D] Insert IC Size | 7.8 mm |

| [D] Insert IC Size | 0.307 in |

| [S] Insert Thickness | 4.698 mm |

| [S] Insert Thickness | 0.185 in |

| [Rε] Corner Radius | 1.225 mm |

| [Rε] Corner Radius | 0.048 in |

공작물 재료

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

재종

TN6540

Coated carbide grade TN6540 has a PVD-TiAlN multilayer and is excellent for medium and heavy

machining applications. It is ideal for use in all steels and nodular cast irons.

특징 및 장점

- -MM geometry provides lower cutting forces. First choice for steel, stainless steel, and high-temp alloys.

이송 및 속도를 계산하려면 솔루션을 생성하세요.

솔루션 생성 후 이송 및 속도 아이콘을 선택하면 추천 값이 제공됩니다. 기계와 사양을 추가하여 사용자 정보를 지정하거나 슬라이더를 사용하여 조정할 수 있습니다.

이송량

권장 초기 이송[mm]

| 경절삭 | 범용 | 중황삭 |

| 인서트 형상 | 프로그래밍된 날당 이송(fz) (반경방향 절삭폭(ae)의 비율) | 인서트 형상 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ..MM | 0,90 | 1,67 | 4,09 | 0,65 | 1,19 | 2,83 | 0,48 | 0,88 | 2,08 | 0,42 | 0,77 | 1,80 | 0,38 | 0,70 | 1,64 | ..MM |

| ..MH | 0,90 | 2,34 | 5,00 | 0,65 | 1,66 | 3,41 | 0,48 | 1,23 | 2,49 | 0,42 | 1,07 | 2,16 | 0,38 | 0,98 | 1,97 | ..MH |

Recommended Starting Feeds [IPT]

| 인서트 형상 | 프로그래밍된 날당 이송(fz) (반경방향 절삭폭(ae)의 비율) | 인서트 형상 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ...MM | .035 | .061 | .150 | .025 | .044 | .104 | .019 | .033 | .076 | .017 | .028 | .066 | .015 | .026 | .061 | ...MM |

| ...MH | .035 | .092 | .197 | .025 | .065 | .134 | .019 | .048 | .098 | .017 | .042 | .085 | .015 | .038 | .078 | ...MH |

| 경절삭 | 범용 | 중황삭 |

속도

| 소재 그룹 | TN6525 | TN6540 | WK15CM | WP25PM | WP35CM | WP40PM | WS30PM | WS40PM | WU35PM | |||||||||||||||||||

| P | 1 | 1340 | 1045 | 925 | 1180 | 925 | 785 | – | – | – | 1295 | 1120 | 1060 | 1790 | 1555 | 1460 | 1165 | 1025 | 965 | – | – | – | – | – | – | 850 | 750 | 705 |

| 2 | 1045 | 830 | 710 | 830 | 630 | 550 | – | – | – | 1080 | 940 | 785 | 1105 | 1000 | 905 | 985 | 845 | 710 | – | – | – | – | – | – | 720 | 620 | 520 | |

| 3 | 925 | 710 | 610 | 710 | 550 | 450 | – | – | – | 1000 | 845 | 690 | 1000 | 905 | 805 | 905 | 770 | 630 | – | – | – | – | – | – | 655 | 555 | 455 | |

| 4 | 770 | 550 | 475 | 590 | 430 | 355 | – | – | – | 890 | 725 | 590 | 750 | 690 | 630 | 805 | 670 | 535 | – | – | – | – | – | – | 590 | 490 | 390 | |

| 5 | 1025 | 770 | 650 | 785 | 590 | 490 | – | – | – | 725 | 670 | 590 | 1025 | 905 | 830 | 670 | 610 | 535 | – | – | – | 560 | 475 | 395 | 490 | 440 | 390 | |

| 6 | 670 | 535 | 430 | 535 | 395 | 335 | – | – | – | 650 | 490 | 395 | 630 | 535 | 430 | 590 | 450 | 355 | – | – | – | 490 | 360 | 260 | 425 | 325 | 260 | |

| M | 1 | 630 | 395 | 260 | 430 | 260 | 200 | – | – | – | 805 | 710 | 650 | 805 | 725 | 610 | 770 | 670 | 610 | 890 | 785 | 725 | 690 | 560 | 460 | 555 | 490 | 440 |

| 2 | 395 | 260 | 155 | 260 | 155 | 140 | – | – | – | 725 | 630 | 510 | 725 | 630 | 550 | 690 | 590 | 490 | 805 | 710 | 570 | 590 | 475 | 395 | 505 | 425 | 360 | |

| 3 | 415 | 260 | 180 | 275 | 155 | 140 | – | – | – | 550 | 475 | 370 | 570 | 510 | 450 | 510 | 450 | 355 | 610 | 535 | 415 | 475 | 360 | 280 | 375 | 325 | 260 | |

| K | 1 | 905 | 805 | 725 | 725 | 670 | 590 | 1655 | 1520 | 1340 | 905 | 805 | 725 | 1165 | 1045 | 940 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 710 | 630 | 590 | 570 | 510 | 450 | 1320 | 1165 | 1080 | 710 | 630 | 590 | 925 | 830 | 750 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 590 | 535 | 475 | 510 | 475 | 415 | 1105 | 985 | 905 | 590 | 535 | 475 | 770 | 690 | 630 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 155 | 120 | 95 | – | – | – | 155 | 140 | 95 | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 130 | 115 | 80 | 110 | 95 | 80 |

| 2 | – | – | – | 80 | 60 | 40 | – | – | – | 155 | 140 | 95 | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 130 | 115 | 80 | 110 | 95 | 80 | |

| 3 | – | – | – | 235 | 140 | 95 | – | – | – | 200 | 155 | 95 | – | – | – | 200 | 155 | 120 | 215 | 180 | 120 | 165 | 130 | 80 | 145 | 110 | 80 | |

| 4 | – | – | – | 200 | 95 | 80 | – | – | – | 275 | 200 | 140 | 260 | 200 | 130 | 260 | 200 | 140 | 335 | 235 | 155 | 195 | 165 | 100 | 195 | 145 | 95 | |

| H | 1 | – | – | – | – | – | – | – | – | – | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

인서트 선택

인서트 선택 가이드

| 경절삭 | 범용 | 중황삭 | ||||

| 소재 그룹 | 형상 | 재종 | 형상 | 재종 | 형상 | 재종 |

| P1–P2 | ...MM | WP40PM | ...MM | WP40PM | ...MM | WP40PM |

| P3–P4 | ...MM | WP25PM | ...MM | WP40PM | ...MH | WP40PM |

| P5–P6 | ...MM | WP25PM | ...MH | WP25PM | ...MH | WP40PM |

| M1–M2 | ...MM | WP25PM | ...MM | WS30PM | ...MM | WP40PM |

| M3 | ...MM | WP25PM | ...MM | WP25PM | ...MM | WP40PM |

| K1–K2 | ...MH | WK15CM | ...MH | WK15CM | ...MH | WK15CM |

| K3 | ...MH | TN6520 | ...MH | TN6520 | ...MH | WK15CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ...MM | WP25PM | ...MM | WS30PM | ...MM | WP40PM |

| S3 | ...MM | WS30PM | ...MM | WS30PM | ...MM | WP40PM |

| S4 | ...MM | WS30PM | ...MM | WP40PM | ...MM | WP40PM |

| H1 | ...MH | WP25PM | – | – | – | – |

I have read and accepted the Terms & Conditions of use