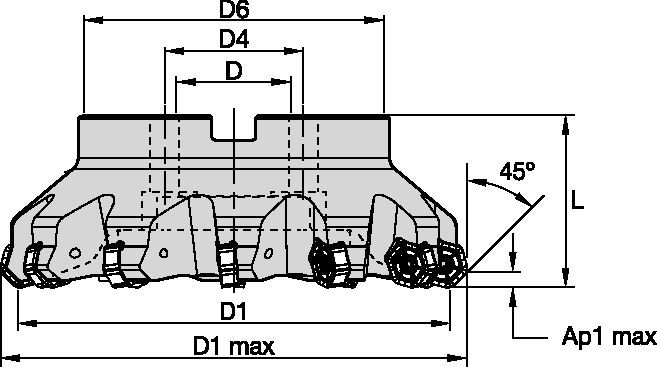

M1200 • 45° • Shell Mills • Inch

45° • Shell Mills • Inch

제품 번호3650541

ISO 카탈로그 IDM1200D400Z06S125HN09ANSI 카탈로그 IDM1200D400Z06S125HN09

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

페이스 밀링

밀링 — 내부 쿨런트

밀링 — 사이드 및 페이스

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 제품 번호 | 3650541 |

| ISO 카탈로그 ID | M1200D400Z06S125HN09 |

| ANSI 카탈로그 ID | M1200D400Z06S125HN09 |

| [D1] Effective Cutting Diameter | 101.6 mm |

| [D1] Effective Cutting Diameter | 4 in |

| [D1MAX] Maximum Cutting Diameter | 112.58 mm |

| [D1MAX] Maximum Cutting Diameter | 4.432 in |

| [D] Adapter / Shank / Bore Diameter | 31.75 mm |

| [D] Adapter / Shank / Bore Diameter | 1.25 in |

| [D6] Hub Diameter | 69.149 mm |

| [D6] Hub Diameter | 2.722 in |

| [L] Overall Length | 44.45 mm |

| [L] Overall Length | 1.75 in |

| [AP1MAX] 1st Maximum Cutting Depth | 4.5 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .177 in |

| Number of Inserts | 6 |

| Max RPM | 6300 |

| Coolant Supply | Y |

| Weight Pounds | 3.17 |

공작물 재료

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

사용 및 응용 분야

페이스 밀링

밀링 — 내부 쿨런트

밀링 — 사이드 및 페이스

특징 및 장점

- Twelve cutting edges.

- First choice for general face milling.

- Low cutting forces for maximum productivity.

이송 및 속도를 계산하려면 솔루션을 생성하세요.

솔루션 생성 후 이송 및 속도 아이콘을 선택하면 추천 값이 제공됩니다. 기계와 사양을 추가하여 사용자 정보를 지정하거나 슬라이더를 사용하여 조정할 수 있습니다.

인서트 선택

인서트 선택 가이드

| Material Group | Light | General | Heavy | Universal | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | .E..LD | WP40PM | .S..GD | WP40PM | .S..HD | WP40PM | .S..MM | WU20PM |

| P3–P4 | .E..LD | WP25PM | .S..GD | WP35CM | .S..HD | WP35CM | .S..MM | WU20PM |

| P5–P6 | .E..LD | WP25PM | .S..GD | WP35CM | .S..HD | WP35CM | .S..MM | WP35CM |

| M1–M2 | .E..LD | WP25PM | .S..GD | WP25PM | .S..HD | WP25PM | .S..MM | WU20PM |

| M3 | .E..LD | WP35CM | .S..GD | WP35CM | .S..HD | WP35CM | .S..MM | WP35CM |

| K1–K2 | .E..LD | TN6520 | .S..GD | WK15CM | .S..HD | WK15CM | .S..MM | WK15CM |

| K3 | .E..LD | WP35CM | .S..GD | WP35CM | .S..HD | WP35CM | .S..MM | WP35CM |

| N1–N2 | .F..LDJ | TN6501 | .F..LDJ | TN6501 | .F..LDJ | TN6501 | ||

| N3 | .F..LDJ | TN6501 | .F..LDJ | TN6501 | .F..LDJ | TN6501 | ||

| S1–S2 | .E..LD | WS30PM | .S..GD | WS30PM | .S..HD | WS40PM | .S..MM | WU20PM |

| S3 | .E..LD | WS30PM | .S..GD | WS30PM | .S..HD | WS40PM | .S..MM | WU20PM |

| S4 | .E..LD | WS30PM | .S..GD | WS30PM | .S..HD | WS40PM | .S..MM | WU20PM |

이송량

권장 초기 이송[mm]

| Light | General | Heavy |

| M1200 15º Lead • Recommended Starting Feeds [mm/th] | ||||||

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | |||||

| 30% | 40 | |||||

| L | M | H | L | M | H | |

| .F..LDJ | 0,22 | 0,42 | 0,83 | 0,21 | 0,38 | 0,76 |

| .E..LD | 0,22 | 0,64 | 1,28 | 0,21 | 0,59 | 1,17 |

| .S..GD | 0,43 | 1,07 | 1,72 | 0,39 | 0,98 | 1,57 |

| .S..HD | 0,43 | 1,07 | 1,72 | 0,39 | 0,98 | 1,57 |

| .S..Ceramic | – | – | – | – | – | – |

| .S..MM | 0,43 | 1,07 | 1,72 | 0,39 | 0,98 | 1,57 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||

| Light | General | Heavy |

| M1200 15º Lead • Recommended Starting Feeds [IPT] | ||||||

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | |||||

| 30% | 40 | |||||

| L | M | H | L | M | H | |

| .F..LDJ | 0.008 | 0.017 | 0.034 | 0.008 | 0.015 | 0.031 |

| .E..LD | 0.008 | 0.025 | 0.051 | 0.008 | 0.023 | 0.046 |

| .S..GD | 0.017 | 0.042 | 0.068 | 0.015 | 0.039 | 0.062 |

| .S..HD | 0.017 | 0.042 | 0.068 | 0.015 | 0.039 | 0.062 |

| .S..Ceramic | – | – | – | – | – | – |

| .S..MM | 0.017 | 0.042 | 0.068 | 0.015 | 0.039 | 0.062 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||

속도

권장 초기 속도[m/min]

| M1200 • Recommended Starting Speeds [m/min] | ||||||||||||||||||||||

| Grade | THM-U | TN6501 | TN6510 | TN6520 | TN6525 | TN6540 | WK15CM | |||||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 410 | 320 | 280 | 360 | 280 | 240 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 320 | 250 | 215 | 250 | 190 | 170 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 280 | 215 | 185 | 215 | 170 | 140 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | – | – | – | |

| K | 1 | – | – | – | – | – | – | 480 | 350 | 260 | 450 | 320 | 230 | 275 | 245 | 220 | 220 | 205 | 180 | 505 | 460 | 410 |

| 2 | – | – | – | – | – | – | 420 | 280 | 205 | 390 | 250 | 190 | 215 | 190 | 180 | 175 | 155 | 140 | 400 | 355 | 330 | |

| 3 | – | – | – | – | – | – | 335 | 260 | 200 | 300 | 230 | 160 | 180 | 160 | 145 | 155 | 145 | 125 | 335 | 300 | 275 | |

| N | 1 | 2400 | 1440 | 1200 | 2400 | 1440 | 1200 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 1640 | 980 | 800 | 1640 | 980 | 800 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 960 | 600 | 480 | 960 | 600 | 480 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 35 | 30 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 25 | 20 | 10 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 70 | 40 | 30 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 30 | 25 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

| M1200 • Recommended Starting Speeds [m/min] | ||||||||||||||||||||||

| Grade | WP25PM | WP35CM | WP40PM | WS30PM | WS40PM | WU20PM | WK25YM | |||||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 395 | 340 | 325 | 545 | 475 | 445 | 355 | 310 | 295 | – | – | – | – | – | – | 330 | 290 | 270 | – | – | – |

| 2 | 330 | 290 | 240 | 335 | 305 | 275 | 300 | 260 | 215 | – | – | – | – | – | – | 275 | 250 | 200 | – | – | – | |

| 3 | 305 | 260 | 210 | 305 | 275 | 245 | 275 | 235 | 190 | – | – | – | – | – | – | 255 | 220 | 175 | – | – | – | |

| 4 | 270 | 220 | 180 | 230 | 210 | 190 | 245 | 205 | 160 | – | – | – | – | – | – | 225 | 190 | 150 | – | – | – | |

| 5 | 220 | 205 | 180 | 310 | 275 | 250 | 205 | 185 | 160 | – | – | – | 205 | 175 | 145 | 185 | 175 | 150 | – | – | – | |

| 6 | 200 | 150 | 120 | 190 | 160 | 130 | 180 | 140 | 110 | – | – | – | 180 | 130 | 95 | 165 | 130 | 100 | – | – | – | |

| M | 1 | 245 | 215 | 200 | 245 | 220 | 185 | 235 | 205 | 185 | 270 | 240 | 220 | 250 | 205 | 170 | 205 | 180 | 165 | – | – | – |

| 2 | 220 | 190 | 155 | 220 | 190 | 170 | 210 | 180 | 150 | 245 | 215 | 175 | 215 | 175 | 145 | 185 | 160 | 130 | – | – | – | |

| 3 | 170 | 145 | 115 | 175 | 155 | 140 | 155 | 140 | 110 | 185 | 160 | 125 | 175 | 130 | 100 | 140 | 120 | 95 | – | – | – | |

| K | 1 | 275 | 245 | 220 | 355 | 320 | 290 | – | – | – | – | – | – | – | – | – | 250 | 220 | 185 | 965 | 880 | 780 |

| 2 | 215 | 190 | 180 | 280 | 250 | 230 | – | – | – | – | – | – | – | – | – | 200 | 180 | 150 | 765 | 685 | 635 | |

| 3 | 180 | 160 | 145 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – | 180 | 150 | 120 | 645 | 570 | 525 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 400 | 350 | 300 | – | – | – | |

| S | 1 | 50 | 40 | 30 | – | – | – | 50 | 40 | 35 | 55 | 50 | 35 | 50 | 40 | 30 | 40 | 35 | 25 | – | – | – |

| 2 | 50 | 40 | 30 | – | – | – | 50 | 40 | 35 | 55 | 50 | 35 | 50 | 40 | 30 | 40 | 35 | 25 | – | – | – | |

| 3 | 60 | 50 | 30 | – | – | – | 60 | 50 | 35 | 65 | 55 | 35 | 60 | 50 | 30 | 50 | 40 | 25 | – | – | – | |

| 4 | 85 | 60 | 40 | 80 | 60 | 40 | 80 | 60 | 40 | 100 | 70 | 50 | 70 | 60 | 35 | 70 | 50 | 35 | – | – | – | |

| H | 1 | 145 | 110 | 85 | – | – | – | – | – | – | – | – | – | – | – | – | 110 | 80 | 70 | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

| M1200 • Recommended Starting Speeds [SFM] | ||||||||||||||||||||||

| Grade | THM-U | TN6501 | TN6510 | TN6520 | TN6525 | TN6540 | WK15CM | |||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 1340 | 1045 | 925 | 1180 | 925 | 785 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 1045 | 830 | 710 | 830 | 630 | 550 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 925 | 710 | 610 | 710 | 550 | 450 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 770 | 550 | 475 | 590 | 430 | 355 | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 1025 | 770 | 650 | 785 | 590 | 490 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 670 | 535 | 430 | 535 | 395 | 335 | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 630 | 395 | 260 | 430 | 260 | 200 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 395 | 260 | 155 | 260 | 155 | 140 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 415 | 260 | 180 | 275 | 155 | 140 | – | – | – | |

| K | 1 | – | – | – | – | – | – | 1570 | 1140 | 845 | 1475 | 1045 | 750 | 905 | 805 | 725 | 725 | 670 | 590 | 1655 | 1520 | 1340 |

| 2 | – | – | – | – | – | – | 1380 | 925 | 670 | 1280 | 830 | 630 | 710 | 630 | 590 | 570 | 510 | 450 | 1320 | 1165 | 1080 | |

| 3 | – | – | – | – | – | – | 1105 | 845 | 650 | 985 | 750 | 535 | 590 | 535 | 475 | 510 | 475 | 415 | 1105 | 985 | 905 | |

| N | 1 | 7870 | 4720 | 3935 | 7870 | 4720 | 3935 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 5370 | 3210 | 2615 | 5370 | 3210 | 2615 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 3150 | 1970 | 1570 | 3150 | 1970 | 1570 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 155 | 120 | 95 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 80 | 60 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 140 | 95 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 200 | 95 | 80 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

| M1200 • Recommended Starting Speeds [SFM] | ||||||||||||||||||||||

| Grade | WP25PM | WP35CM | WP40PM | WS30PM | WS40PM | WU20PM | WK25YM | |||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 1295 | 1120 | 1060 | 1790 | 1555 | 1460 | 970 | 855 | 805 | – | – | – | – | – | – | 1080 | 950 | 890 | – | – | – |

| 2 | 1080 | 940 | 785 | 1105 | 1000 | 905 | 820 | 705 | 590 | – | – | – | – | – | – | 900 | 820 | 660 | – | – | – | |

| 3 | 1000 | 845 | 690 | 1000 | 905 | 805 | 755 | 640 | 525 | – | – | – | – | – | – | 840 | 720 | 570 | – | – | – | |

| 4 | 890 | 725 | 590 | 750 | 690 | 630 | 675 | 560 | 445 | – | – | – | – | – | – | 740 | 620 | 490 | – | – | – | |

| 5 | 725 | 670 | 590 | 1025 | 905 | 830 | 560 | 510 | 445 | – | – | – | 560 | 475 | 395 | 610 | 570 | 490 | – | – | – | |

| 6 | 650 | 490 | 395 | 630 | 535 | 430 | 490 | 375 | 295 | – | – | – | 490 | 360 | 260 | 540 | 430 | 330 | – | – | – | |

| M | 1 | 805 | 710 | 650 | 805 | 725 | 610 | 640 | 560 | 510 | 890 | 785 | 725 | 690 | 560 | 460 | 670 | 590 | 540 | – | – | – |

| 2 | 725 | 630 | 510 | 725 | 630 | 550 | 575 | 490 | 410 | 805 | 710 | 570 | 590 | 475 | 395 | 610 | 520 | 430 | – | – | – | |

| 3 | 550 | 475 | 370 | 570 | 510 | 450 | 425 | 375 | 295 | 610 | 535 | 415 | 475 | 360 | 280 | 460 | 390 | 310 | – | – | – | |

| K | 1 | 905 | 805 | 725 | 1165 | 1045 | 940 | – | – | – | – | – | – | – | – | – | 820 | 720 | 610 | 3170 | 2880 | 2560 |

| 2 | 710 | 630 | 590 | 925 | 830 | 750 | – | – | – | – | – | – | – | – | – | 660 | 590 | 490 | 2510 | 2240 | 2090 | |

| 3 | 590 | 535 | 475 | 770 | 690 | 630 | – | – | – | – | – | – | – | – | – | 590 | 490 | 390 | 2110 | 1870 | 1720 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1310 | 1150 | 980 | – | – | – | |

| S | 1 | 155 | 140 | 95 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 | 130 | 110 | 80 | – | – | – |

| 2 | 155 | 140 | 95 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 | 130 | 110 | 80 | – | – | – | |

| 3 | 200 | 155 | 95 | – | – | – | – | – | – | 215 | 180 | 120 | 165 | 130 | 80 | 160 | 130 | 80 | – | – | – | |

| 4 | 275 | 200 | 140 | 260 | 200 | 130 | – | – | – | 335 | 235 | 155 | 195 | 165 | 100 | 230 | 160 | 110 | – | – | – | |

| H | 1 | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – | – | – | – | 360 | 260 | 230 | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

I have read and accepted the Terms & Conditions of use