*に類似する製品:

VSM490™-10 • Shell Mills • Inch

Shell Mills • Inch

製品番号6425389

ISO カタログ IDVSM490D250Z05S075XN10ASIカタログIDVSM490D250Z05S075XN10

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

フェイスミーリング

溝加工:スクエアエンド

ミーリング — スルークーラント

ミーリング — 側面および正面

側面加工/ショルダー加工:スクエアエンド

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

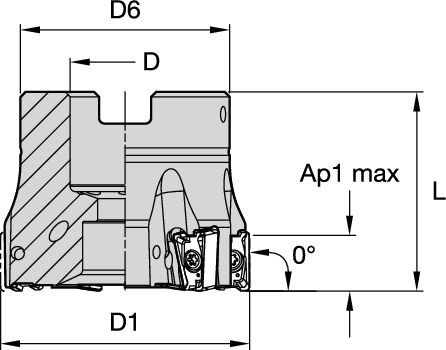

| 製品番号 | 6425389 |

| ISO カタログ ID | VSM490D250Z05S075XN10 |

| ASIカタログID | VSM490D250Z05S075XN10 |

| [D1] Effective Cutting Diameter | 63.5 mm |

| [D1] Effective Cutting Diameter | 2.5 in |

| [D] Adapter / Shank / Bore Diameter | 19.05 mm |

| [D] Adapter / Shank / Bore Diameter | 0.75 in |

| [D6] Hub Diameter | 44.45 mm |

| [D6] Hub Diameter | 1.928 in |

| [L] Overall Length | 40.05 mm |

| [L] Overall Length | 1.577 in |

| [AP1MAX] 1st Maximum Cutting Depth | 10 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.394 in |

| Number of Inserts | 5 |

| Max RPM | 22100 |

| Coolant Supply | Y |

| Weight Pounds | 1.25 |

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

使用法と用途

フェイスミーリング

溝加工:スクエアエンド

ミーリング — スルークーラント

ミーリング — 側面および正面

側面加工/ショルダー加工:スクエアエンド

特徴と利点

- True 0° roughing tool with imbedded finishing capability all in one tool

- Best-in-class wall finish in axial stepping-down jobs

- Lower cutting forces and real soft cutting action

- Perfect fit for taper 40 spindles and driven units

- Coarse, medium, and fine pitch cutter density available

- Cutters following Japanese Industry Standard (JIS) are available

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

送り量

推奨フィード量の開始値[mm]

| 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | ||||||||||||||||

| インサート ブレーカ形状 | 5% | 10% | 20% | 30% | 40–100% | インサート ブレーカ形状 | ||||||||||

| .E..ALP | 0,12 | 0,23 | 0,32 | 0,08 | 0,17 | 0,23 | 0,06 | 0,13 | 0,18 | 0,06 | 0,11 | 0,15 | 0,05 | 0,10 | 0,14 | .E..ALP |

| .E..ML | 0,18 | 0,28 | 0,37 | 0,13 | 0,20 | 0,27 | 0,10 | 0,15 | 0,20 | 0,09 | 0,13 | 0,17 | 0,08 | 0,12 | 0,16 | .E..ML |

| .S..MM | 0,23 | 0,35 | 0,46 | 0,17 | 0,25 | 0,33 | 0,13 | 0,19 | 0,25 | 0,11 | 0,17 | 0,22 | 0,10 | 0,15 | 0,20 | .S..MM |

| .S..MH | 0,23 | 0,43 | 0,58 | 0,17 | 0,31 | 0,42 | 0,13 | 0,23 | 0,31 | 0,11 | 0,20 | 0,27 | 0,10 | 0,18 | 0,25 | .S..MH |

| 軽切削加工 | 汎用 | 重切削加工 |

Recommended Starting Feeds [IPT]

| 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | ||||||||||||||||

| インサート ブレーカ形状 | 5% | 10% | 20% | 30% | 40–100% | インサート ブレーカ形状 | ||||||||||

| .E..ALP | .005 | .009 | .013 | .003 | .007 | .009 | .003 | .005 | .007 | .002 | .004 | .006 | .002 | .004 | .006 | .E..ALP |

| .E..ML | .007 | .011 | .015 | .005 | .008 | .011 | .004 | .006 | .008 | .003 | .005 | .007 | .003 | .005 | .006 | .E..ML |

| .S..MM | .009 | .014 | .018 | .007 | .010 | .013 | .005 | .007 | .010 | .004 | .006 | .008 | .004 | .006 | .008 | .S..MM |

| .S..MH | .009 | .016 | .022 | .007 | .012 | .016 | .005 | .009 | .012 | .004 | .008 | .010 | .004 | .007 | .010 | .S..MH |

| 軽切削加工 | 汎用 | 重切削加工 |

速度

推奨切削速度の開始値[m/min]*

| 被削材 グループ | WK15CM | WK15PM | WK15PM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU10PM | |||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 330 | 285 | 270 | 455 | 395 | 370 | 295 | 260 | 245 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 275 | 240 | 200 | 280 | 255 | 230 | 250 | 215 | 180 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 255 | 215 | 175 | 255 | 230 | 205 | 230 | 195 | 160 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 225 | 185 | 150 | 190 | 175 | 160 | 205 | 170 | 135 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 185 | 170 | 150 | 260 | 230 | 210 | 170 | 155 | 135 | 170 | 145 | 120 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 125 | 100 | 160 | 135 | 110 | 150 | 115 | 90 | 150 | 110 | 80 | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 205 | 180 | 165 | 205 | 185 | 155 | 195 | 170 | 155 | 210 | 170 | 140 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 185 | 160 | 130 | 185 | 160 | 140 | 175 | 150 | 125 | 180 | 145 | 120 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 140 | 120 | 95 | 145 | 130 | 115 | 130 | 115 | 90 | 145 | 110 | 85 | – | – | – | |

| K | 1 | 420 | 385 | 340 | 270 | 245 | 215 | 360 | 290 | 245 | – | – | – | 230 | 205 | 185 | 295 | 265 | 240 | – | – | – | – | – | – | 295 | 265 | 240 |

| 2 | 335 | 295 | 275 | 210 | 190 | 175 | 280 | 230 | 195 | – | – | – | 180 | 160 | 150 | 235 | 210 | 190 | – | – | – | – | – | – | 230 | 205 | 190 | |

| 3 | 280 | 250 | 230 | 175 | 160 | 145 | 210 | 175 | 140 | – | – | – | 150 | 135 | 120 | 195 | 175 | 160 | – | – | – | – | – | – | 195 | 175 | 160 | |

| N | 1 | – | – | – | – | – | – | – | – | – | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 70 | 50 | 35 | – | – | – | – | – | – | 60 | 50 | 30 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 130 | 90 |

Recommended Starting Speeds [SFM]*

| 被削材 グループ | WK15CM | WK15PM | WK15PM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU10PM | |||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 1085 | 935 | 885 | 1495 | 1295 | 1215 | 970 | 855 | 805 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 900 | 785 | 655 | 920 | 835 | 755 | 820 | 705 | 590 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 835 | 705 | 575 | 835 | 755 | 675 | 755 | 640 | 525 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 740 | 605 | 490 | 625 | 575 | 525 | 675 | 560 | 445 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 605 | 560 | 490 | 855 | 755 | 690 | 560 | 510 | 445 | 560 | 475 | 395 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 540 | 410 | 330 | 525 | 445 | 360 | 490 | 375 | 295 | 490 | 360 | 260 | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 675 | 590 | 540 | 675 | 605 | 510 | 640 | 560 | 510 | 690 | 560 | 460 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 605 | 525 | 425 | 605 | 525 | 460 | 575 | 490 | 410 | 590 | 475 | 395 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 460 | 395 | 310 | 475 | 425 | 375 | 425 | 375 | 295 | 475 | 360 | 280 | – | – | – | |

| K | 1 | 1380 | 1265 | 1115 | 885 | 805 | 705 | 1180 | 950 | 805 | – | – | – | 755 | 675 | 605 | 970 | 870 | 785 | – | – | – | – | – | – | 970 | 870 | 785 |

| 2 | 1100 | 970 | 900 | 690 | 625 | 575 | 920 | 755 | 640 | – | – | – | 590 | 525 | 490 | 770 | 690 | 625 | – | – | – | – | – | – | 755 | 675 | 625 | |

| 3 | 920 | 820 | 755 | 575 | 525 | 475 | 690 | 575 | 460 | – | – | – | 490 | 445 | 395 | 640 | 575 | 525 | – | – | – | – | – | – | 640 | 575 | 525 | |

| N | 1 | – | – | – | – | – | – | – | – | – | 3525 | 3100 | 2870 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 130 | 80 | – | – | – | 165 | 130 | 100 | 165 | 130 | 80 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 230 | 165 | 115 | – | – | – | 215 | 165 | 115 | 195 | 165 | 100 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 525 | 425 | 295 |

インサート選択

インサート選択の手引き

| 軽切削加工 | 汎用 | 重切削加工 | ||||

| 被削材 グループ | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 |

| P1–P2 | XNGU-ML | WP40PM | XNPU-MM | WP40PM | XNPU-MM | WP40PM |

| P3–P4 | XNGU-ML | WP40PM | XNPU-MM | WP40PM | XNPU-MM | WP40PM |

| P5–P6 | XNGU-MM | WP25PM | XNPU-MM | WP35CM | XNPU-MM | WP40PM |

| M1–M2 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| M3 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| K1–K2 | XNPU-ML | WK15PM | XNGU-MH | WK15CM | XNGU-MH | WK15CM |

| K3 | XNPU-MM | WK15PM | XNGU-MH | WP35CM | XNGU-MH | WP35CM |

| N1–N2 | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM |

| N3 | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM |

| S1–S2 | XNGU-ML | WP25PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| S3 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| S4 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| H1 | XNGU-ML | WU10PM | XNGU-MM | WU10PM | – | – |

I have read and accepted the Terms & Conditions of use