*に類似する製品:

M390 • SDMT-MH • SD1204..

インサート • SD1204..

製品番号3325040

ISO カタログ IDSDMT1204PDRMHANSIカタログIDSDMT43PDRMH

- P Steel

- M Stainless Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 3325040 |

| ISO カタログ ID | SDMT1204PDRMH |

| ANSIカタログID | SDMT43PDRMH |

| Grade | TN6525 |

| Cutting Edges per Insert | 4 |

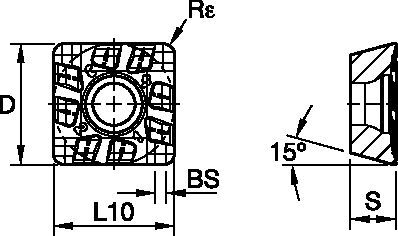

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | .5 in |

| [L10] Insert Cutting Edge Length | 12.7 mm |

| [L10] Insert Cutting Edge Length | .5 in |

| [S] Insert Thickness | 4.809 mm |

| [S] Insert Thickness | .1893 in |

| [BS] Corner Facet Length | 1.1 mm |

| [BS] Corner Facet Length | .043 in |

| [Rε] Corner Radius | 1.2 mm |

| [Rε] Corner Radius | .0469 in |

| Average Chip Thickness [HM] | 0.14 mm |

| Average Chip Thickness [HM] | .0055 in |

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

等級

TN6525

Carbide grade TN6525 has aPVD-TiAlN multilayer. It is ideal for light and medium machining

applications in steels and high-strength nodular cast irons.

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

インサート選択

インサート選択の手引き

| 被削材 グループ | 軽切削加工 | 汎用 | 重切削加工 | |||

| ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | |

| P1–P2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P3–P4 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| P5–P6 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M1–M2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MH | TN6540 |

| M3 | .E..ML | WP35CM | .S..MM | WS30PM | .S..MH | WP35CM |

| K1–K2 | .E..ML | WK15CM | .E..ML | WK15CM | .S..MH | WK15CM |

| K3 | .E..ML | WK15CM | .S..MM | TN6525 | .S..MH | TN6525 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .E..ML | TN6540 | .S..MM | TN6540 | .S..MM | TN6540 |

| S3 | .E..ML | TN6540 | .S..MM | WS30PM | .S..MM | TN6540 |

| S4 | .E..ML | TN6540 | .S..MM | WS30PM | .S..MM | TN6540 |

| H1 | .S..MM | WS30PM | .S..MM | WS30PM | .S..MM | WS30PM |

送り量

推奨フィード量の開始値[mm]

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 30 % | 20 % | 10 % | 40 | ||||||||||||

| .F..ALP | 0,12 | 0,23 | 0,46 | 0,08 | 0,17 | 0,33 | 0,06 | 0,13 | 0,25 | 0,06 | 0,11 | 0,22 | 0,05 | 0,10 | 0,20 | .F..ALP |

| .E..ML | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | .E..ML |

| .S..MM | 0,12 | 0,42 | 0,70 | 0,08 | 0,30 | 0,50 | 0,06 | 0,23 | 0,38 | 0,06 | 0,20 | 0,33 | 0,05 | 0,18 | 0,30 | .S..MM |

| .S..MH | 0,23 | 0,54 | 0,85 | 0,17 | 0,39 | 0,61 | 0,13 | 0,29 | 0,46 | 0,11 | 0,25 | 0,40 | 0,10 | 0,23 | 0,36 | .S..MH |

| 軽切削加工 | 汎用 | 重切削加工 |

速度

推奨切削速度の開始値[m/min]

| 被削材 グループ | THM-U | TN6520 | TN6525 | TN6540 | TTM08 | |||||||||||

| P | 0 | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | – | – | – |

| 1 | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | 230 | 200 | 190 | |

| 2 | – | – | – | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | 195 | 170 | 140 | |

| 3 | – | – | – | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | 180 | 150 | 125 | |

| 4 | – | – | – | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | 160 | 130 | 105 | |

| 5 | – | – | – | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | – | – | – | |

| 6 | – | – | – | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 | – | – | – |

| 2 | – | – | – | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | – | – | – | |

| 3 | – | – | – | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | – | – | – | |

| K | 1 | 190 | 170 | 150 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 | – | – | – |

| 2 | – | – | – | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | – | – | – | |

| 3 | – | – | – | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | – | – | – | |

| N | 1 | 2000 | 1200 | 1000 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 1365 | 815 | 665 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 800 | 500 | 400 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 40 | 30 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 20 | 15 | 10 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 60 | 35 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | 50 | 25 | 20 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 被削材 グループ | WK15CM | WP25PM | WP35CM | WP40PM | WS30PM | WS40PM | |||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 1 | – | – | – | 330 | 285 | 270 | 455 | 395 | 370 | 295 | 260 | 245 | – | – | – | 280 | 245 | 230 | |

| 2 | – | – | – | 275 | 240 | 200 | 280 | 255 | 230 | 250 | 215 | 180 | – | – | – | 235 | 205 | 170 | |

| 3 | – | – | – | 255 | 215 | 175 | 255 | 230 | 205 | 230 | 195 | 160 | – | – | – | 215 | 185 | 150 | |

| 4 | – | – | – | 225 | 185 | 150 | 190 | 175 | 160 | 205 | 170 | 135 | – | – | – | 195 | 160 | 130 | |

| 5 | – | – | – | 185 | 170 | 150 | 260 | 230 | 210 | 170 | 155 | 135 | – | – | – | 160 | 140 | 130 | |

| 6 | – | – | – | 165 | 125 | 100 | 160 | 135 | 110 | 150 | 115 | 90 | – | – | – | 140 | 110 | 85 | |

| M | 1 | – | – | – | 205 | 180 | 165 | 205 | 185 | 155 | 195 | 170 | 155 | 225 | 200 | 185 | 260 | 190 | 115 |

| 2 | – | – | – | 185 | 160 | 130 | 185 | 160 | 140 | 175 | 150 | 125 | 205 | 180 | 145 | 230 | 170 | 105 | |

| 3 | – | – | – | 140 | 120 | 95 | 145 | 130 | 115 | 130 | 115 | 90 | 155 | 135 | 105 | 190 | 140 | 80 | |

| K | 1 | 420 | 385 | 340 | 230 | 205 | 185 | 295 | 265 | 240 | – | – | – | – | – | – | – | – | – |

| 2 | 335 | 295 | 275 | 180 | 160 | 150 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – | |

| 3 | 280 | 250 | 230 | 150 | 135 | 120 | 195 | 175 | 160 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1075 | 945 | 945 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 945 | 875 | 845 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 875 | 760 | 760 | |

| S | 1 | – | – | – | 40 | 35 | 25 | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 62 | 45 | 27 |

| 2 | – | – | – | 40 | 35 | 25 | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 55 | 40 | 26 | |

| 3 | – | – | – | 50 | 40 | 25 | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | 64 | 46 | 29 | |

| 4 | – | – | – | 70 | 50 | 35 | 66 | 50 | 33 | 65 | 50 | 35 | 85 | 60 | 40 | 90 | 66 | 42 | |

| H | 1 | – | – | – | 120 | 90 | 70 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use