*に類似する製品:

M100 • シェルミルRC1606..•メトリック

シェルミル • RC1606 • メトリック

製品番号2021352

ISO カタログ ID12391022000ANSIカタログID12391022000

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

フェイスミーリング

ヘリカルミーリング

ランピング加工:ブランク

溝加工:スクエアエンド

側面加工/ショルダー加工:ボールノーズ

3Dプロファイル加工

ミーリング — スルークーラント

ミーリング — 側面および正面

ポケット溝加工

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

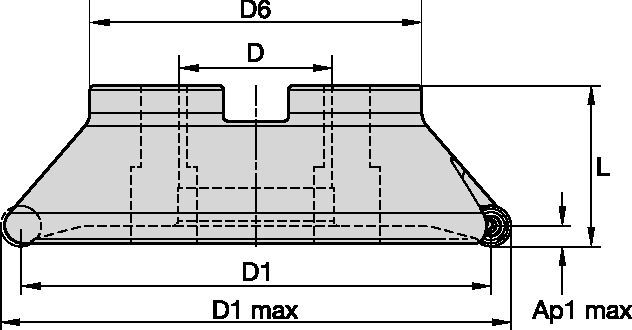

| 製品番号 | 2021352 |

| ISO カタログ ID | 12391022000 |

| ANSIカタログID | 12391022000 |

| Grade | W |

| [D1MAX] Maximum Cutting Diameter | 80 mm |

| [D1MAX] Maximum Cutting Diameter | 3.15 in |

| [D1] Effective Cutting Diameter | 64 mm |

| [D1] Effective Cutting Diameter | 2.519 in |

| [D] Adapter / Shank / Bore Diameter | 27 mm |

| [D] Adapter / Shank / Bore Diameter | 1.063 in |

| [D6] Hub Diameter | 60 mm |

| [D6] Hub Diameter | 2.362 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.968 in |

| [AP1MAX] 1st Maximum Cutting Depth | 8 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .315 in |

| Number of Inserts | 6 |

| Maximum Ramping Angle | 2.75 |

| Max RPM | 10000 |

| Coolant Supply | Y |

| Weight Kilograms | 0.9 |

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

使用法と用途

フェイスミーリング

ヘリカルミーリング

ランピング加工:ブランク

溝加工:スクエアエンド

側面加工/ショルダー加工:ボールノーズ

3Dプロファイル加工

ミーリング — スルークーラント

ミーリング — 側面および正面

ポケット溝加工

特徴と利点

- General purpose face and copy milling

- Anti-rotation feature for top security

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

インサート選択

インサート選択の手引き

| 軽切削加工 | 汎用 | 重切削加工 | ||||

| 被削材 グループ | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 |

| P1–P2 | RDMT-TX | TN6525 | RDMT-TX | TN6540 | RDMT-TX | TN6540 |

| P3–P4 | RDMT-TX | TN6525 | RDMW-TX | TN6540 | RDMW-TX | TN6540 |

| P5–P6 | RDMT-TX | WP35CM | RDMT-TX | WP35CM | RDMT-TX | WP35CM |

| M1–M2 | RDMT-TX | TN6525 | RDMT-TX | TN6540 | RDMT-TX | TN6540 |

| M3 | RDMT-TX | TN6525 | RDMT-TX | TN6540 | RDMT-TX | TN6540 |

| K1–K2 | RDMW-TX | TN2510 | RDMW-TX | WP35CM | RDMW-TX | WP35CM |

| K3 | RDMW-TX | TN2510 | RDMW-TX | WP35CM | RDMW-TX | WP35CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | RDMT-TX | TN6540 | – | – |

| S3 | – | – | RDMT-TX | TN6540 | – | – |

| S4 | – | – | RDMT-TX | TN6540 | RDMT-TX | TN6540 |

| H1 | RDMW-TX | TN2510 | RDMW-TX | TN2510 | – | – |

インサート選択の手引き

| 軽切削加工 | 汎用 | 重切削加工 | ||||

| 被削材 グループ | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 |

| P1–P2 | ...TX | TN6525 | ...43M | TN6540 | ...43M | TN6540 |

| P3–P4 | ...TX | TN6525 | ...TX | TN6540 | ...43M | TN6540 |

| P5–P6 | ...TX | TN6525 | ...TX | WP35CM | ...TX | WP35CM |

| M1–M2 | ...TX | TN6525 | ...TX | TN6540 | ...TX | TN6540 |

| M3 | ...TX | TN6525 | ...TX | TN6540 | ...TX | TN6540 |

| K1–K2 | ...43 | TN2510 | ...TX | WK15CM | ...TX | WK15CM |

| K3 | ...TX | TN6525 | ...TX | WK15CM | ...TX | WK15CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | ...43M | TN6540 | ...TX | TN6540 | ...TX | TN6540 |

| H1 | – | – | ...TX | TN2510 | – | – |

送り量

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| RDHX-TX | 0,11 | 0,35 | 0,70 | 0,08 | 0,25 | 0,50 | 0,06 | 0,19 | 0,38 | 0,05 | 0,16 | 0,33 | 0,05 | 0,15 | 0,30 | RDHX-TX |

| RDMT-TX | 0,23 | 0,42 | 0,84 | 0,17 | 0,30 | 0,60 | 0,13 | 0,23 | 0,45 | 0,11 | 0,20 | 0,39 | 0,10 | 0,18 | 0,36 | RDMT-TX |

| RDMW-TX | 0,23 | 0,52 | 1,05 | 0,17 | 0,38 | 0,76 | 0,13 | 0,28 | 0,56 | 0,11 | 0,25 | 0,49 | 0,10 | 0,23 | 0,45 | RDMW-TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| RDHX-TX | 0,13 | 0,40 | 0,81 | 0,10 | 0,29 | 0,58 | 0,07 | 0,22 | 0,43 | 0,06 | 0,19 | 0,38 | 0,06 | 0,17 | 0,35 | RDHX-TX |

| RDMT-TX | 0,27 | 0,48 | 0,97 | 0,19 | 0,35 | 0,70 | 0,14 | 0,26 | 0,52 | 0,13 | 0,23 | 0,45 | 0,12 | 0,21 | 0,42 | RDMT-TX |

| RDMW-TX | 0,27 | 0,60 | 1,22 | 0,19 | 0,44 | 0,87 | 0,14 | 0,33 | 0,65 | 0,13 | 0,28 | 0,57 | 0,12 | 0,26 | 0,52 | RDMW-TX |

| 軽切削加工 | 汎用 | 重切削加工 |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| RDHX-TX | 0,24 | 0,72 | 1,46 | 0,17 | 0,52 | 1,04 | 0,13 | 0,39 | 0,78 | 0,11 | 0,34 | 0,68 | 0,10 | 0,31 | 0,62 | RDHX-TX |

| RDMT-TX | 0,48 | 0,87 | 1,76 | 0,35 | 0,62 | 1,26 | 0,26 | 0,47 | 0,93 | 0,23 | 0,41 | 0,81 | 0,21 | 0,37 | 0,74 | RDMT-TX |

| RDMW-TX | 0,48 | 1,09 | 2,22 | 0,35 | 0,78 | 1,58 | 0,26 | 0,58 | 1,17 | 0,23 | 0,51 | 1,02 | 0,21 | 0,46 | 0,93 | RDMW-TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| RDHX-TX | 0,17 | 0,53 | 1,06 | 0,13 | 0,38 | 0,76 | 0,09 | 0,28 | 0,57 | 0,08 | 0,25 | 0,50 | 0,08 | 0,23 | 0,45 | RDHX-TX |

| RDMT-TX | 0,35 | 0,63 | 1,28 | 0,25 | 0,46 | 0,92 | 0,19 | 0,34 | 0,68 | 0,17 | 0,30 | 0,59 | 0,15 | 0,27 | 0,54 | RDMT-TX |

| RDMW-TX | 0,35 | 0,79 | 1,61 | 0,25 | 0,57 | 1,15 | 0,19 | 0,43 | 0,85 | 0,17 | 0,37 | 0,74 | 0,15 | 0,34 | 0,68 | RDMW-TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ...43 | 0,46 | 0,60 | 0,93 | 0,33 | 0,44 | 0,67 | 0,25 | 0,33 | 0,50 | 0,22 | 0,28 | 0,44 | 0,20 | 0,26 | 0,40 | ...43 |

| ...TX | 0,46 | 0,70 | 1,12 | 0,33 | 0,50 | 0,81 | 0,25 | 0,38 | 0,60 | 0,22 | 0,33 | 0,52 | 0,20 | 0,30 | 0,48 | ...TX |

| 軽切削加工 | 汎用 | 重切削加工 |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ...43 | 0,54 | 0,70 | 1,08 | 0,39 | 0,50 | 0,78 | 0,29 | 0,38 | 0,58 | 0,25 | 0,33 | 0,50 | 0,23 | 0,30 | 0,46 | ...43 |

| ...TX | 0,54 | 0,81 | 1,30 | 0,39 | 0,58 | 0,93 | 0,29 | 0,43 | 0,69 | 0,25 | 0,38 | 0,61 | 0,23 | 0,35 | 0,55 | ...TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ...43 | 0,96 | 1,26 | 1,97 | 0,69 | 0,90 | 1,40 | 0,52 | 0,67 | 1,04 | 0,45 | 0,59 | 0,90 | 0,41 | 0,54 | 0,83 | ...43 |

| ...TX | 0,96 | 1,46 | 2,38 | 0,69 | 1,04 | 1,68 | 0,52 | 0,78 | 1,25 | 0,45 | 0,68 | 1,08 | 0,41 | 0,62 | 0,99 | ...TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ...43 | 0,70 | 0,92 | 1,42 | 0,51 | 0,66 | 1,02 | 0,38 | 0,49 | 0,76 | 0,33 | 0,43 | 0,66 | 0,30 | 0,39 | 0,60 | ...43 |

| ...TX | 0,70 | 1,06 | 1,72 | 0,51 | 0,76 | 1,23 | 0,38 | 0,57 | 0,91 | 0,33 | 0,50 | 0,79 | 0,30 | 0,45 | 0,73 | ...TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| RDHX-TX | .005 | .014 | .027 | .003 | .010 | .020 | .002 | .007 | .015 | .002 | .006 | .013 | .002 | .006 | .012 | RDHX-TX |

| RDMT-TX | .009 | .016 | .033 | .007 | .012 | .024 | .005 | .009 | .018 | .004 | .008 | .016 | .004 | .007 | .014 | RDMT-TX |

| RDMW-TX | .009 | .020 | .041 | .007 | .015 | .030 | .005 | .011 | .022 | .004 | .010 | .019 | .004 | .009 | .018 | RDMW-TX |

| 軽切削加工 | 汎用 | 重切削加工 |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| RDHX-TX | .009 | .028 | .057 | .007 | .020 | .041 | .005 | .015 | .030 | .004 | .013 | .027 | .004 | .012 | .024 | RDHX-TX |

| RDMT-TX | .019 | .034 | .070 | .014 | .025 | .050 | .010 | .018 | .037 | .009 | .016 | .032 | .008 | .015 | .029 | RDMT-TX |

| RDMW-TX | .019 | .043 | .088 | .014 | .031 | .062 | .010 | .023 | .046 | .009 | .020 | .040 | .008 | .018 | .037 | RDMW-TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| RDHX-TX | .005 | .016 | .032 | .004 | .011 | .023 | .003 | .008 | .017 | .002 | .007 | .015 | .002 | .007 | .014 | RDHX-TX |

| RDMT-TX | .010 | .019 | .038 | .008 | .014 | .028 | .006 | .010 | .021 | .005 | .009 | .018 | .005 | .008 | .016 | RDMT-TX |

| RDMW-TX | .010 | .024 | .048 | .008 | .017 | .034 | .006 | .013 | .026 | .005 | .011 | .022 | .005 | .010 | .020 | RDMW-TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| RDHX-TX | .007 | .021 | .042 | .005 | .015 | .030 | .004 | .011 | .022 | .003 | .010 | .019 | .003 | .009 | .018 | RDHX-TX |

| RDMT-TX | .014 | .025 | .050 | .010 | .018 | .036 | .007 | .013 | .027 | .006 | .012 | .023 | .006 | .011 | .021 | RDMT-TX |

| RDMW-TX | .014 | .031 | .063 | .010 | .022 | .045 | .007 | .017 | .034 | .006 | .015 | .029 | .006 | .013 | .027 | RDMW-TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ...43 | .018 | .024 | .037 | .013 | .017 | .027 | .010 | .013 | .020 | .009 | .011 | .017 | .008 | .010 | .016 | ...43 |

| ...TX | .018 | .027 | .044 | .013 | .020 | .032 | .010 | .015 | .024 | .009 | .013 | .021 | .008 | .012 | .019 | ...TX |

| 軽切削加工 | 汎用 | 重切削加工 |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ...43 | .021 | .028 | .043 | .015 | .020 | .031 | .011 | .015 | .023 | .010 | .013 | .020 | .009 | .012 | .018 | ...43 |

| ...TX | .021 | .032 | .051 | .015 | .023 | .037 | .011 | .017 | .027 | .010 | .015 | .024 | .009 | .014 | .022 | ...TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ...43 | .038 | .050 | .078 | .027 | .036 | .055 | .020 | .027 | .041 | .018 | .023 | .036 | .016 | .021 | .033 | ...43 |

| ...TX | .038 | .058 | .093 | .027 | .041 | .066 | .020 | .031 | .049 | .018 | .027 | .042 | .016 | .024 | .039 | ...TX |

| インサート ブレーカ形状 | 1刃あたりの送り (fz) 径方向の切込み量(ae)に対する割合(%) | インサート ブレーカ形状 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ...43 | .028 | .036 | .056 | .020 | .026 | .040 | .015 | .019 | .030 | .013 | .017 | .026 | .012 | .016 | .024 | ...43 |

| ...TX | .028 | .042 | .067 | .020 | .030 | .048 | .015 | .022 | .036 | .013 | .019 | .031 | .012 | .018 | .028 | ...TX |

速度

推奨切削速度の開始値[m/min]

| 被削材 グループ | THM | TN6525 | TN6540 | TTM08 | WK15CM | WP35CM | WS30PM | WS40PM | |||||||||||||||||

| P | 1 | – | – | – | 410 | 320 | 280 | 360 | 280 | 240 | 230 | 200 | 190 | – | – | – | 455 | 395 | 370 | – | – | – | – | – | – |

| 2 | – | – | – | 320 | 250 | 215 | 250 | 190 | 170 | 195 | 170 | 140 | – | – | – | 280 | 255 | 230 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 215 | 185 | 215 | 170 | 140 | 180 | 150 | 125 | – | – | – | 255 | 230 | 205 | – | – | – | – | – | – | |

| 4 | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | 160 | 130 | 105 | – | – | – | 190 | 175 | 160 | – | – | – | – | – | – | |

| 5 | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | – | – | – | – | – | – | 260 | 230 | 210 | – | – | – | 205 | 175 | 145 | |

| 6 | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | – | – | – | – | – | – | 160 | 135 | 110 | – | – | – | 180 | 130 | 95 | |

| M | 1 | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 | – | – | – | – | – | – | 205 | 185 | 155 | 270 | 240 | 220 | 250 | 205 | 170 |

| 2 | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | – | – | – | – | – | – | 185 | 160 | 140 | 245 | 215 | 175 | 215 | 175 | 145 | |

| 3 | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | – | – | – | – | – | – | 145 | 130 | 115 | 185 | 160 | 125 | 175 | 130 | 100 | |

| K | 1 | 120 | 90 | 75 | 275 | 245 | 220 | 220 | 205 | 180 | – | – | – | 505 | 460 | 410 | 295 | 265 | 240 | – | – | – | – | – | – |

| 2 | 125 | 100 | 70 | 215 | 190 | 180 | 175 | 155 | 140 | – | – | – | 400 | 355 | 330 | 235 | 210 | 190 | – | – | – | – | – | – | |

| 3 | 130 | 95 | 60 | 180 | 160 | 145 | 155 | 145 | 125 | – | – | – | 335 | 300 | 275 | 195 | 175 | 160 | – | – | – | – | – | – | |

| N | 1 | 900 | 600 | 500 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 35 | 30 | – | – | – | – | – | – | – | – | – | 55 | 50 | 35 | 50 | 40 | 30 |

| 2 | – | – | – | – | – | – | 25 | 20 | 10 | – | – | – | – | – | – | – | – | – | 55 | 50 | 35 | 50 | 40 | 30 | |

| 3 | – | – | – | – | – | – | 70 | 40 | 30 | – | – | – | – | – | – | – | – | – | 65 | 55 | 35 | 60 | 50 | 30 | |

| 4 | – | – | – | – | – | – | 60 | 30 | 25 | – | – | – | – | – | – | 66 | 50 | 33 | 100 | 70 | 50 | 70 | 60 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

推奨切削速度の開始値[m/min]

| 被削材 グループ | THM | TN6525 | TN6540 | TTM08 | WK15CM | WP35CM | WS30PM | WS40PM | |||||||||||||||||

| P | 1 | – | – | – | 410 | 320 | 280 | 360 | 280 | 240 | 230 | 200 | 190 | – | – | – | 455 | 395 | 370 | – | – | – | – | – | – |

| 2 | – | – | – | 320 | 250 | 215 | 250 | 190 | 170 | 195 | 170 | 140 | – | – | – | 280 | 255 | 230 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 215 | 185 | 215 | 170 | 140 | 180 | 150 | 125 | – | – | – | 255 | 230 | 205 | – | – | – | – | – | – | |

| 4 | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | 160 | 130 | 105 | – | – | – | 190 | 175 | 160 | – | – | – | – | – | – | |

| 5 | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | – | – | – | – | – | – | 260 | 230 | 210 | – | – | – | 205 | 175 | 145 | |

| 6 | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | – | – | – | – | – | – | 160 | 135 | 110 | – | – | – | 180 | 130 | 95 | |

| M | 1 | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 | – | – | – | – | – | – | 205 | 185 | 155 | 270 | 240 | 220 | 250 | 205 | 170 |

| 2 | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | – | – | – | – | – | – | 185 | 160 | 140 | 245 | 215 | 175 | 215 | 175 | 145 | |

| 3 | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | – | – | – | – | – | – | 145 | 130 | 115 | 185 | 160 | 125 | 175 | 130 | 100 | |

| K | 1 | 120 | 90 | 75 | 275 | 245 | 220 | 220 | 205 | 180 | – | – | – | 505 | 460 | 410 | 295 | 265 | 240 | – | – | – | – | – | – |

| 2 | 125 | 100 | 70 | 215 | 190 | 180 | 175 | 155 | 140 | – | – | – | 400 | 355 | 330 | 235 | 210 | 190 | – | – | – | – | – | – | |

| 3 | 130 | 95 | 60 | 180 | 160 | 145 | 155 | 145 | 125 | – | – | – | 335 | 300 | 275 | 195 | 175 | 160 | – | – | – | – | – | – | |

| N | 1 | 900 | 600 | 500 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 35 | 30 | – | – | – | – | – | – | – | – | – | 55 | 50 | 35 | 50 | 40 | 30 |

| 2 | – | – | – | – | – | – | 25 | 20 | 10 | – | – | – | – | – | – | – | – | – | 55 | 50 | 35 | 50 | 40 | 30 | |

| 3 | – | – | – | – | – | – | 70 | 40 | 30 | – | – | – | – | – | – | – | – | – | 65 | 55 | 35 | 60 | 50 | 30 | |

| 4 | – | – | – | – | – | – | 60 | 30 | 25 | – | – | – | – | – | – | 66 | 50 | 33 | 100 | 70 | 50 | 70 | 60 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| 被削材 グループ | THM | TN6525 | TN6540 | WP35CM | |||||||||

| P | 1 | – | – | – | 1340 | 1045 | 925 | 1180 | 925 | 785 | 1790 | 1555 | 1460 |

| 2 | – | – | – | 1045 | 830 | 710 | 830 | 630 | 550 | 1105 | 1000 | 905 | |

| 3 | – | – | – | 925 | 710 | 610 | 710 | 550 | 450 | 1000 | 905 | 805 | |

| 4 | – | – | – | 770 | 550 | 475 | 590 | 430 | 355 | 750 | 690 | 630 | |

| 5 | – | – | – | 1025 | 770 | 650 | 785 | 590 | 490 | 1025 | 905 | 830 | |

| 6 | – | – | – | 670 | 535 | 430 | 535 | 395 | 335 | 630 | 535 | 430 | |

| M | 1 | – | – | – | 630 | 395 | 260 | 430 | 260 | 200 | 805 | 725 | 610 |

| 2 | – | – | – | 395 | 260 | 155 | 260 | 155 | 140 | 725 | 630 | 550 | |

| 3 | – | – | – | 415 | 260 | 180 | 275 | 155 | 140 | 570 | 510 | 450 | |

| K | 1 | 390 | 295 | 245 | 905 | 805 | 725 | 725 | 670 | 590 | 1165 | 1045 | 940 |

| 2 | 410 | 325 | 225 | 710 | 630 | 590 | 570 | 510 | 450 | 925 | 830 | 750 | |

| 3 | 425 | 310 | 195 | 590 | 535 | 475 | 510 | 475 | 415 | 770 | 690 | 630 | |

| N | 1 | 2950 | 1965 | 1640 | – | – | – | – | – | – | – | – | – |

| 2 | 2245 | 1525 | 1260 | – | – | – | – | – | – | – | – | – | |

| 3 | 1475 | 915 | 655 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 155 | 120 | 95 | – | – | – |

| 2 | – | – | – | – | – | – | 80 | 60 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | 235 | 140 | 95 | – | – | – | |

| 4 | – | – | – | – | – | – | 200 | 95 | 80 | 260 | 200 | 130 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 被削材 グループ | TTM08 | WK15CM | WS30PM | WS40PM | |||||||||

| P | 1 | 750 | 655 | 620 | – | – | – | – | – | – | – | – | – |

| 2 | 635 | 555 | 455 | – | – | – | – | – | – | – | – | – | |

| 3 | 590 | 490 | 410 | – | – | – | – | – | – | – | – | – | |

| 4 | 520 | 425 | 340 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | 560 | 475 | 395 | |

| 6 | – | – | – | – | – | – | – | – | – | 490 | 360 | 260 | |

| M | 1 | – | – | – | – | – | – | 890 | 785 | 725 | 690 | 560 | 460 |

| 2 | – | – | – | – | – | – | 805 | 710 | 570 | 590 | 475 | 395 | |

| 3 | – | – | – | – | – | – | 610 | 535 | 415 | 475 | 360 | 280 | |

| K | 1 | – | – | – | 1655 | 1520 | 1340 | – | – | – | – | – | – |

| 2 | – | – | – | 1320 | 1165 | 1080 | – | – | – | – | – | – | |

| 3 | – | – | – | 1105 | 985 | 905 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 |

| 2 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 | |

| 3 | – | – | – | – | – | – | 215 | 180 | 120 | 165 | 130 | 80 | |

| 4 | – | – | – | – | – | – | 335 | 235 | 155 | 195 | 165 | 100 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| 被削材 グループ | THM | TN6525 | TN6540 | WP35CM | |||||||||

| P | 1 | – | – | – | 1340 | 1045 | 925 | 1180 | 925 | 785 | 1790 | 1555 | 1460 |

| 2 | – | – | – | 1045 | 830 | 710 | 830 | 630 | 550 | 1105 | 1000 | 905 | |

| 3 | – | – | – | 925 | 710 | 610 | 710 | 550 | 450 | 1000 | 905 | 805 | |

| 4 | – | – | – | 770 | 550 | 475 | 590 | 430 | 355 | 750 | 690 | 630 | |

| 5 | – | – | – | 1025 | 770 | 650 | 785 | 590 | 490 | 1025 | 905 | 830 | |

| 6 | – | – | – | 670 | 535 | 430 | 535 | 395 | 335 | 630 | 535 | 430 | |

| M | 1 | – | – | – | 630 | 395 | 260 | 430 | 260 | 200 | 805 | 725 | 610 |

| 2 | – | – | – | 395 | 260 | 155 | 260 | 155 | 140 | 725 | 630 | 550 | |

| 3 | – | – | – | 415 | 260 | 180 | 275 | 155 | 140 | 570 | 510 | 450 | |

| K | 1 | 390 | 295 | 245 | 905 | 805 | 725 | 725 | 670 | 590 | 1165 | 1045 | 940 |

| 2 | 410 | 325 | 225 | 710 | 630 | 590 | 570 | 510 | 450 | 925 | 830 | 750 | |

| 3 | 425 | 310 | 195 | 590 | 535 | 475 | 510 | 475 | 415 | 770 | 690 | 630 | |

| N | 1 | 2950 | 1965 | 1640 | – | – | – | – | – | – | – | – | – |

| 2 | 2245 | 1525 | 1260 | – | – | – | – | – | – | – | – | – | |

| 3 | 1475 | 915 | 655 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 155 | 120 | 95 | – | – | – |

| 2 | – | – | – | – | – | – | 80 | 60 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | 235 | 140 | 95 | – | – | – | |

| 4 | – | – | – | – | – | – | 200 | 95 | 80 | 260 | 200 | 130 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 被削材 グループ | TTM08 | WK15CM | WS30PM | WS40PM | |||||||||

| P | 1 | 750 | 655 | 620 | – | – | – | – | – | – | – | – | – |

| 2 | 635 | 555 | 455 | – | – | – | – | – | – | – | – | – | |

| 3 | 590 | 490 | 410 | – | – | – | – | – | – | – | – | – | |

| 4 | 520 | 425 | 340 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | 560 | 475 | 395 | |

| 6 | – | – | – | – | – | – | – | – | – | 490 | 360 | 260 | |

| M | 1 | – | – | – | – | – | – | 890 | 785 | 725 | 690 | 560 | 460 |

| 2 | – | – | – | – | – | – | 805 | 710 | 570 | 590 | 475 | 395 | |

| 3 | – | – | – | – | – | – | 610 | 535 | 415 | 475 | 360 | 280 | |

| K | 1 | – | – | – | 1655 | 1520 | 1340 | – | – | – | – | – | – |

| 2 | – | – | – | 1320 | 1165 | 1080 | – | – | – | – | – | – | |

| 3 | – | – | – | 1105 | 985 | 905 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 |

| 2 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 | |

| 3 | – | – | – | – | – | – | 215 | 180 | 120 | 165 | 130 | 80 | |

| 4 | – | – | – | – | – | – | 335 | 235 | 155 | 195 | 165 | 100 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use