Produit similaire à:

VSM890™-12 • Fraises 2 tailles • Métrique

Fraises 2 tailles • Métrique

Numéro de matériel6596069

Ref. ISO CatalogueVSM890D050Z05S22SN12Ref. ANSI CatalogueVSM890D050Z05S22SN12

- P Acier

- M Acier inoxydable

- K Fonte

- N Non ferreux

- S Alliages hautes températures

- H Matériaux trempés

100018357

Rainurage : Bout plat

Fraisage — Arrosage interne

Fraisage — 3 tailles

Fraisage de côté/avec épaulement : Bout plat

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Aperçu

- Données d'application

- Téléchargements

- Pièces compatibles côté machine

- Pièces compatibles côté pièce

- Pièces de rechange

- Révision

- FAQ

| Numéro de matériel | 6596069 |

| Ref. ISO Catalogue | VSM890D050Z05S22SN12 |

| Ref. ANSI Catalogue | VSM890D050Z05S22SN12 |

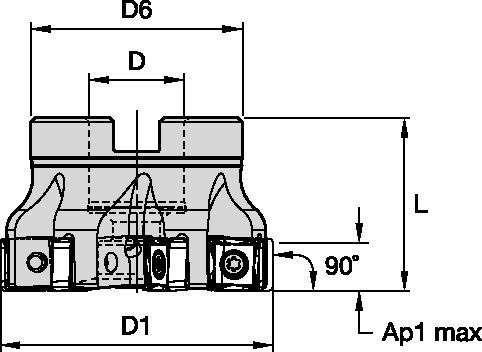

| [D1] Diamètre effectif de coupe | 50 mm |

| [D1] Diamètre effectif de coupe | 1.968 in |

| [D] Adaptateur / Queue / Diamètre d’alésage | 22 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | .8666 in |

| [D6] Diamètre du moyeu | 49 mm |

| [D6] Diamètre du moyeu | 1.929 in |

| [L] Longueur totale | 40 mm |

| [L] Longueur totale | 1.574 in |

| [AP1MAX] 1re profondeur de coupe maximale | 9.8 mm |

| [AP1MAX] 1re profondeur de coupe maximale | .3872 in |

| Nombre de plaquettes | 5 |

| T/Min max | 24100 |

| Alimentation en arrosage | Y |

| Poids en kilogrammes | 0.32 |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Non ferreux

- Alliages hautes températures

- Matériaux trempés

Uses and application

100018357

Rainurage : Bout plat

Fraisage — Arrosage interne

Fraisage — 3 tailles

Fraisage de côté/avec épaulement : Bout plat

Features and benefits

- Capacité de paroi à 90° vrais et d’abaissement.

- Conception de cannelure à copeau optimisée pour une excellente évacuation des copeaux.

- Système convivial de numérotation du logement.

- Corps de fraise avec arrosage interne.

- Moins de bavures sur la pièce.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Guide de sélection des plaquettes

| Travaux légers | Applications générales | Travaux lourds | ||||

| Groupe Matières | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | SNHX-ML | WS40PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| P3–P4 | SNHX-ML | WS40PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| P5–P6 | SNHX-ML | WP25PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| M1–M2 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| M3 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| K1–K2 | SNHX-MM | WK15CM | SNHX-MM | WK15CM | SNHX-MM | WK15CM |

| K3 | SNHX-MM | WK15CM | SNHX-MM | WK15CM | SNHX-MM | WK15CM |

| N1–N2 | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM |

| N3 | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM |

| S1–S2 | SNHX-ML | WP25PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| S3 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| S4 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| H1 | SNHX-MM | WU10PM | SNHX-MM | WU10PM | – | – |

Feeds

Avances de départ recommandées [mm]

| Avance par dent (fz) programmée en % de l'engagement radial (ae) | ||||||||||||||||

| Géométrie de plaquette | 5% | 10% | 20% | 30% | 40–100% | Géométrie de plaquette | ||||||||||

| .E..ALP | 0,12 | 0,28 | 0,43 | 0,08 | 0,20 | 0,31 | 0,06 | 0,15 | 0,23 | 0,06 | 0,13 | 0,20 | 0,05 | 0,12 | 0,18 | .E..ALP |

| .E..ML | 0,17 | 0,32 | 0,60 | 0,13 | 0,23 | 0,44 | 0,09 | 0,18 | 0,33 | 0,08 | 0,15 | 0,28 | 0,08 | 0,14 | 0,26 | .E..ML |

| .S..MM | 0,23 | 0,36 | 0,82 | 0,17 | 0,26 | 0,59 | 0,13 | 0,20 | 0,44 | 0,11 | 0,17 | 0,38 | 0,10 | 0,16 | 0,35 | .S..MM |

| Travaux légers | Applications générales | Travaux lourds |

Avances de départ recommandées [IPT]

| Avance par dent (fz) programmée en % de l'engagement radial (ae) | ||||||||||||||||

| Géométrie de plaquette | 5% | 10% | 20% | 30% | 40–100% | Géométrie de plaquette | ||||||||||

| .E..ALP | .005 | .010 | .015 | .003 | .007 | .011 | .003 | .005 | .008 | .002 | .005 | .007 | .002 | .004 | .006 | .E..ALP |

| .E..ML | .007 | .012 | .023 | .005 | .009 | .017 | .004 | .007 | .012 | .003 | .006 | .011 | .003 | .005 | .010 | .E..ML |

| .S..MM | .009 | .014 | .032 | .007 | .010 | .023 | .005 | .008 | .017 | .004 | .007 | .015 | .004 | .006 | .014 | .S..MM |

| Travaux légers | Applications générales | Travaux lourds |

Speeds

Vitesses de départ recommandées [m/mn]*

| Groupe Matières | WK15CM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU10PM | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 330 | 285 | 270 | 455 | 395 | 370 | 295 | 260 | 245 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 275 | 240 | 200 | 280 | 255 | 230 | 250 | 215 | 180 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 255 | 215 | 175 | 255 | 230 | 205 | 230 | 195 | 160 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 225 | 185 | 150 | 190 | 175 | 160 | 205 | 170 | 135 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | 185 | 170 | 150 | 260 | 230 | 210 | 170 | 155 | 135 | 170 | 145 | 120 | – | – | – | |

| 6 | – | – | – | – | – | – | 165 | 125 | 100 | 160 | 135 | 110 | 150 | 115 | 90 | 150 | 110 | 80 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 205 | 180 | 165 | 205 | 185 | 155 | 195 | 170 | 155 | 210 | 170 | 140 | – | – | – |

| 2 | – | – | – | – | – | – | 185 | 160 | 130 | 185 | 160 | 140 | 175 | 150 | 125 | 180 | 145 | 120 | – | – | – | |

| 3 | – | – | – | – | – | – | 140 | 120 | 95 | 145 | 130 | 115 | 130 | 115 | 90 | 145 | 110 | 85 | – | – | – | |

| K | 1 | 420 | 385 | 340 | – | – | – | 230 | 205 | 185 | 295 | 265 | 240 | – | – | – | – | – | – | 295 | 265 | 240 |

| 2 | 335 | 295 | 275 | – | – | – | 180 | 160 | 150 | 235 | 210 | 190 | – | – | – | – | – | – | 230 | 205 | 190 | |

| 3 | 280 | 250 | 230 | – | – | – | 150 | 135 | 120 | 195 | 175 | 160 | – | – | – | – | – | – | 195 | 175 | 160 | |

| N | 1 | – | – | – | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | 70 | 50 | 35 | – | – | – | – | – | – | 60 | 50 | 30 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 130 | 90 |

Vitesses de départ recommandées [SFM]*

| Groupe Matières | WK15CM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU10PM | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 1085 | 935 | 885 | 1490 | 1295 | 1210 | 970 | 855 | 805 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 900 | 785 | 655 | 915 | 835 | 750 | 820 | 705 | 590 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 835 | 705 | 575 | 835 | 750 | 670 | 755 | 640 | 525 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 740 | 605 | 490 | 620 | 570 | 520 | 675 | 560 | 445 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | 605 | 560 | 490 | 850 | 750 | 685 | 560 | 510 | 445 | 560 | 475 | 395 | – | – | – | |

| 6 | – | – | – | – | – | – | 540 | 410 | 330 | 520 | 440 | 360 | 490 | 375 | 295 | 490 | 360 | 260 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 675 | 590 | 540 | 670 | 605 | 505 | 640 | 560 | 510 | 690 | 560 | 460 | – | – | – |

| 2 | – | – | – | – | – | – | 605 | 525 | 425 | 605 | 520 | 455 | 575 | 490 | 410 | 590 | 475 | 395 | – | – | – | |

| 3 | – | – | – | – | – | – | 460 | 395 | 310 | 475 | 425 | 375 | 425 | 375 | 295 | 475 | 360 | 280 | – | – | – | |

| K | 1 | 1380 | 1265 | 1115 | – | – | – | 755 | 675 | 605 | 965 | 865 | 785 | – | – | – | – | – | – | 970 | 870 | 785 |

| 2 | 1100 | 970 | 900 | – | – | – | 590 | 525 | 490 | 770 | 685 | 620 | – | – | – | – | – | – | 755 | 675 | 625 | |

| 3 | 920 | 820 | 755 | – | – | – | 490 | 445 | 395 | 635 | 570 | 520 | – | – | – | – | – | – | 640 | 575 | 525 | |

| N | 1 | – | – | – | 3525 | 3100 | 2870 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | – | – | – |

| 2 | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | – | – | – | |

| 3 | – | – | – | – | – | – | 165 | 130 | 80 | – | – | – | 165 | 130 | 100 | 165 | 130 | 80 | – | – | – | |

| 4 | – | – | – | – | – | – | 230 | 165 | 115 | 215 | 160 | 105 | 215 | 165 | 115 | 195 | 165 | 100 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 525 | 425 | 295 |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use