Soustružení železničních kol

Filtry

Filtry

Zobrazit filtry v

MetrickéPalcové

Workpiece Material

Workpiece Material

- P Steel (9)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(9)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(9)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(9)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(9)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(9)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(9)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(9)

- M Stainless Steel (1)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(1)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(1)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(1)

- K Cast Iron (8)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(8)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(8)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(8)

Select All Star

- US (1)

Applications

Applications

CRT Profiling (8)

Face Milling (8)

Multiple Direction Cutting (8)

Cutting Condition

Cutting Condition

- Heavily Interrupted Cut (8)

- Lightly Interrupted Cut (8)

- Smooth Cut (8)

Tool Cutting Edge Angle

Tool Cutting Edge Angle

- 90.0 (8)

komu

Cutting Edges Per Insert

Cutting Edges Per Insert

- 4.0 (7)

- 8.0 (1)

komu

Internal Coolant Capability

Internal Coolant Capability

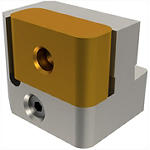

Over All Length [L]

Over All Length [L]

- 1.185 in(2)

- 1.661 in(6)

- 9.843 in(2)

- 10.866 in(2)

komu

Over All Length [L]

Over All Length [L]

- 30.1 mm(2)

- 42.2 mm(6)

- 250.0 mm(2)

- 276.0 mm(2)

komu

Corner Radius

Corner Radius

- 0.095 in(1)

- 0.157 in(11)

komu

Corner Radius

Corner Radius

- 2.401 mm(1)

- 4.0 mm(11)

komu

Corner Chamfer

Corner Chamfer

- 0.0 mm(12)

komu

Corner Chamfer

Corner Chamfer

- 0.0 in(12)

komu

application

Minimum Depth of Cut

Minimum Depth of Cut

Minimum Feed

Minimum Feed

Grade Of Cutting Tool

Grade Of Cutting Tool

- AT15S (1)

- TN5020 (4)

- TN5120 (4)

- TN7015 (4)

- TN7115 (4)

- TTR (1)

- WK20CT (8)

- WP15CT (6)

Wiper Insert

Wiper Insert

- N (8)

frontEnd

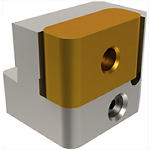

Clamp Style

Clamp Style

- X (8)

Insert Shape

Insert Shape

- L-RECTANGLE 90 (8)

- L-RECTANGLE ON EDGE 90 (8)

Gage Length

Gage Length

- 9.843 in(2)

- 10.866 in(2)

Gage Length

Gage Length

- 250 mm(2)

- 276 mm(2)

insertGeometry

Shape

Shape

- L-RECTANGLE 90 (8)

Cutting Edge Length

Cutting Edge Length

- 19.05 mm(4)

- 30.0 mm(3)

- 40.0 mm(1)

komu

Cutting Edge Length

Cutting Edge Length

- 0.75 in(4)

- 1.181 in(3)

- 1.575 in(1)

komu

Chip Breaker CBMD

Chip Breaker CBMD

- 13 (2)

- 16 (1)

- EN95 (1)

- T (4)

Cutting Tool Material

Cutting Tool Material

- H W (12)

Tolerance Class

Tolerance Class

- U (8)

No filters matching ""