Produto semelhante ao:

VSM890™-12 • Fresas de facear • Métrico

Fresas de facear • Métrico

Número de material6596114

ID do catálogo ISOVSM890D080Z09S27SN12ID do catálogo ANSIVSM890D080Z09S27SN12

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

100018357

Abertura de canal: topo reto

Fresamento — Refrigeração interna

Fresamento — Lateral e de face

Fresamento lateral/fresamento de canto: topo reto

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Visão geral

- Dados de aplicação

- Transferências

- Lado da máquina de peças compatíveis

- Lado da peça de peças compatíveis

- Peças de substituição

- Revisão

- Q&A

| Número de material | 6596114 |

| ID do catálogo ISO | VSM890D080Z09S27SN12 |

| ID do catálogo ANSI | VSM890D080Z09S27SN12 |

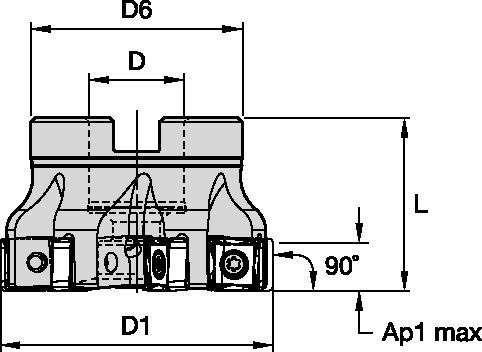

| [D1] Effective Cutting Diameter | 80 mm |

| [D1] Effective Cutting Diameter | 3.149 in |

| [D] Adapter / Shank / Bore Diameter | 27 mm |

| [D] Adapter / Shank / Bore Diameter | 1.063 in |

| [D6] Hub Diameter | 60 mm |

| [D6] Hub Diameter | 2.362 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.968 in |

| [AP1MAX] 1st Maximum Cutting Depth | 9.8 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .3872 in |

| Number of Inserts | 9 |

| Max RPM | 18000 |

| Coolant Supply | Y |

| Weight Kilograms | 1.01 |

Materiais das peças

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Usos e aplicações

100018357

Abertura de canal: topo reto

Fresamento — Refrigeração interna

Fresamento — Lateral e de face

Fresamento lateral/fresamento de canto: topo reto

Características e benefícios

- Parede real de 90° e capacidade de redução.

- Design da estria de cavaco otimizado para permitir uma evacuação de cavacos adequada.

- Sistema de numeração de encaixe de fácil compreensão para o usuário.

- Corpos de fresas com suprimento de refrigeração interna.

- Menos criação de rebarba na peça.

Criar solução para calcular avanços e velocidade

Após criar uma solução basta escolher o ícone Avanços & Velocidades e o nosso sistema irá fornecer recomendações. Pode personalizar as informações adicionando a sua máquina e especificações ou fazer ajustes utilizando os controlos deslizantes.

Seleção de insertos

Guia de seleção de insertos

| Light | General | Heavy | ||||

| Material | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | SNHX-ML | WS40PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| P3–P4 | SNHX-ML | WS40PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| P5–P6 | SNHX-ML | WP25PM | SNHX-MM | WP40PM | SNHX-MM | WP40PM |

| M1–M2 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| M3 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| K1–K2 | SNHX-MM | WK15CM | SNHX-MM | WK15CM | SNHX-MM | WK15CM |

| K3 | SNHX-MM | WK15CM | SNHX-MM | WK15CM | SNHX-MM | WK15CM |

| N1–N2 | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM |

| N3 | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM | SNHX-ALP | WN25PM |

| S1–S2 | SNHX-ML | WP25PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| S3 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| S4 | SNHX-ML | WS40PM | SNHX-ML | WS40PM | SNHX-MM | WS40PM |

| H1 | SNHX-MM | WU10PM | SNHX-MM | WU10PM | – | – |

Avanços

Avanços iniciais recomendados [mm]

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| .E..ALP | 0,12 | 0,28 | 0,43 | 0,08 | 0,20 | 0,31 | 0,06 | 0,15 | 0,23 | 0,06 | 0,13 | 0,20 | 0,05 | 0,12 | 0,18 | .E..ALP |

| .E..ML | 0,17 | 0,32 | 0,60 | 0,13 | 0,23 | 0,44 | 0,09 | 0,18 | 0,33 | 0,08 | 0,15 | 0,28 | 0,08 | 0,14 | 0,26 | .E..ML |

| .S..MM | 0,23 | 0,36 | 0,82 | 0,17 | 0,26 | 0,59 | 0,13 | 0,20 | 0,44 | 0,11 | 0,17 | 0,38 | 0,10 | 0,16 | 0,35 | .S..MM |

| Light | General | Heavy |

Avanços recomendados iniciais [IPT]

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| .E..ALP | .005 | .010 | .015 | .003 | .007 | .011 | .003 | .005 | .008 | .002 | .005 | .007 | .002 | .004 | .006 | .E..ALP |

| .E..ML | .007 | .012 | .023 | .005 | .009 | .017 | .004 | .007 | .012 | .003 | .006 | .011 | .003 | .005 | .010 | .E..ML |

| .S..MM | .009 | .014 | .032 | .007 | .010 | .023 | .005 | .008 | .017 | .004 | .007 | .015 | .004 | .006 | .014 | .S..MM |

| Light | General | Heavy |

Velocidades

Velocidades iniciais recomendadas [m/min]*

| Material Group | WK15CM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU10PM | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 330 | 285 | 270 | 455 | 395 | 370 | 295 | 260 | 245 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 275 | 240 | 200 | 280 | 255 | 230 | 250 | 215 | 180 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 255 | 215 | 175 | 255 | 230 | 205 | 230 | 195 | 160 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 225 | 185 | 150 | 190 | 175 | 160 | 205 | 170 | 135 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | 185 | 170 | 150 | 260 | 230 | 210 | 170 | 155 | 135 | 170 | 145 | 120 | – | – | – | |

| 6 | – | – | – | – | – | – | 165 | 125 | 100 | 160 | 135 | 110 | 150 | 115 | 90 | 150 | 110 | 80 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 205 | 180 | 165 | 205 | 185 | 155 | 195 | 170 | 155 | 210 | 170 | 140 | – | – | – |

| 2 | – | – | – | – | – | – | 185 | 160 | 130 | 185 | 160 | 140 | 175 | 150 | 125 | 180 | 145 | 120 | – | – | – | |

| 3 | – | – | – | – | – | – | 140 | 120 | 95 | 145 | 130 | 115 | 130 | 115 | 90 | 145 | 110 | 85 | – | – | – | |

| K | 1 | 420 | 385 | 340 | – | – | – | 230 | 205 | 185 | 295 | 265 | 240 | – | – | – | – | – | – | 295 | 265 | 240 |

| 2 | 335 | 295 | 275 | – | – | – | 180 | 160 | 150 | 235 | 210 | 190 | – | – | – | – | – | – | 230 | 205 | 190 | |

| 3 | 280 | 250 | 230 | – | – | – | 150 | 135 | 120 | 195 | 175 | 160 | – | – | – | – | – | – | 195 | 175 | 160 | |

| N | 1 | – | – | – | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | |

| 4 | – | – | – | – | – | – | 70 | 50 | 35 | – | – | – | – | – | – | 60 | 50 | 30 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 130 | 90 |

Velocidades iniciais recomendadas (SFM)*

| Material Group | WK15CM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU10PM | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 1085 | 935 | 885 | 1490 | 1295 | 1210 | 970 | 855 | 805 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 900 | 785 | 655 | 915 | 835 | 750 | 820 | 705 | 590 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 835 | 705 | 575 | 835 | 750 | 670 | 755 | 640 | 525 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 740 | 605 | 490 | 620 | 570 | 520 | 675 | 560 | 445 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | 605 | 560 | 490 | 850 | 750 | 685 | 560 | 510 | 445 | 560 | 475 | 395 | – | – | – | |

| 6 | – | – | – | – | – | – | 540 | 410 | 330 | 520 | 440 | 360 | 490 | 375 | 295 | 490 | 360 | 260 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 675 | 590 | 540 | 670 | 605 | 505 | 640 | 560 | 510 | 690 | 560 | 460 | – | – | – |

| 2 | – | – | – | – | – | – | 605 | 525 | 425 | 605 | 520 | 455 | 575 | 490 | 410 | 590 | 475 | 395 | – | – | – | |

| 3 | – | – | – | – | – | – | 460 | 395 | 310 | 475 | 425 | 375 | 425 | 375 | 295 | 475 | 360 | 280 | – | – | – | |

| K | 1 | 1380 | 1265 | 1115 | – | – | – | 755 | 675 | 605 | 965 | 865 | 785 | – | – | – | – | – | – | 970 | 870 | 785 |

| 2 | 1100 | 970 | 900 | – | – | – | 590 | 525 | 490 | 770 | 685 | 620 | – | – | – | – | – | – | 755 | 675 | 625 | |

| 3 | 920 | 820 | 755 | – | – | – | 490 | 445 | 395 | 635 | 570 | 520 | – | – | – | – | – | – | 640 | 575 | 525 | |

| N | 1 | – | – | – | 3525 | 3100 | 2870 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | – | – | – |

| 2 | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | – | – | – | |

| 3 | – | – | – | – | – | – | 165 | 130 | 80 | – | – | – | 165 | 130 | 100 | 165 | 130 | 80 | – | – | – | |

| 4 | – | – | – | – | – | – | 230 | 165 | 115 | 215 | 160 | 105 | 215 | 165 | 115 | 195 | 165 | 100 | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 525 | 425 | 295 |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use