- K 铸铁

- N 非铁材质

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 6425779 |

| 公制样本编号 | XDET16M540FRALP |

| 英制样本编号 | XDET16M540FRALP |

| 材质 | WN10HM |

| 每个刀片的切削刃 | 2 |

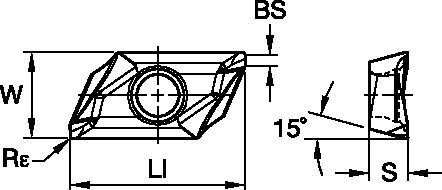

| [LI] 刀片长度 | 23.02 mm |

| [LI] 刀片长度 | 0.906 in |

| [S] 刀片厚度 | 5 mm |

| [S] 刀片厚度 | 0.1969 in |

| [W] 刀片宽度 | 11.25 mm |

| [W] 刀片宽度 | 0.443 in |

| [BS] 刀尖刃口长度 | 0.6 mm |

| [BS] 刀尖刃口长度 | 0.023 in |

| [Rε] 刀尖半径 | 4.1 mm |

| [Rε] 刀尖半径 | 0.161 in |

| 结果工件半径 | 4 mm |

| 结果工件半径 | 0.157 in |

| 平均切屑厚度 [HM] | 0.02 mm |

| 平均切屑厚度 [HM] | 0.0008 in |

工件材料

- 铸铁

- 非铁材质

Features and benefits

- 超大正前角 ALP 刀片槽型。

- 抛光的前刀面,减少积屑瘤。

- 锋利刃口处理 "FRALP" 适用于粗加工和精加工应用。

- 倒圆刃口处理 "ERALP" 适用于重型粗加工应用。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

建议的初始进给量 [毫米]

| 刀片槽型 | 每齿进给量设定值 (fz) 切削宽度 (ae)与刀盘直径百分比 | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | 0,12 | 0,45 | 0,81 | 0,08 | 0,33 | 0,58 | 0,06 | 0,25 | 0,43 | 0,06 | 0,21 | 0,38 | 0,05 | 0,20 | 0,35 | .F..ALP |

| .E..ALP | 0,15 | 0,50 | 0,92 | 0,11 | 0,36 | 0,66 | 0,08 | 0,27 | 0,50 | 0,07 | 0,24 | 0,43 | 0,07 | 0,22 | 0,40 | .E..ALP |

| 轻切削 | 中等切削 | 重切削 |

Recommended Starting Feeds [IPT]

| 刀片槽型 | 每齿进给量设定值 (fz) 切削宽度 (ae)与刀盘直径百分比 | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | .005 | .018 | .032 | .003 | .013 | .023 | .003 | .010 | .017 | .002 | .009 | .015 | .002 | .008 | .014 | .F..ALP |

| .E..ALP | .006 | .020 | .037 | .004 | .014 | .027 | .003 | .011 | .020 | .003 | .009 | .017 | .003 | .009 | .016 | .E..ALP |

| 轻切削 | 中等切削 | 重切削 |

Speeds

湿式加工的建议初始速度 [米/分钟]

| 材料 分组 | WN10HM | |||

| N | 1 | 2950 | 1800 | 875 |

| 2 | 2950 | 1800 | 875 | |

| 3 | 1600 | 850 | 480 | |

Recommended Starting Speeds for Wet Machining [SFM]

| 材料 分组 | WN10HM | |||

| N | 1 | 9640 | 5880 | 2860 |

| 2 | 9640 | 5880 | 2860 | |

| 3 | 5230 | 2775 | 1565 | |

High Performance Combination Tools

刀片选择指南

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 | |

| N1–N2 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

| N3 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

I have read and accepted the Terms & Conditions of use