Product Similar To:

WGC Cut-Off Inserts • F Precision Ground • Inch

Cut-Off Inserts • F Precision Ground • Inch

Material Number6686088

ISO Catalog IDWC125I03PR06F0ANSI Catalog IDWC125I03PR06F0

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6686088 |

| ISO Catalog ID | WC125I03PR06F0 |

| ANSI Catalog ID | WC125I03PR06F0 |

| Grade | WU10PT |

| Insert Size | 3 |

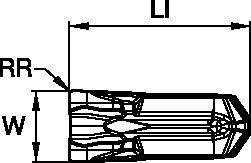

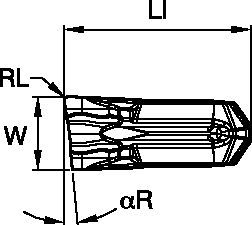

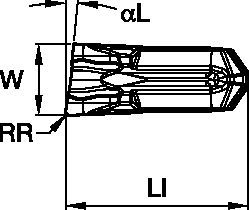

| [W] Cutting Width | 3.175 mm |

| [W] Cutting Width | .125 in |

| Cuttg Width (+/-) Tolerance | 0.025 mm |

| Cuttg Width (+/-) Tolerance | .001 in |

| [LI] Insert Length | 9.626 mm |

| [LI] Insert Length | .379 in |

| Cutting Edge Angle Right Hand | 6 |

| [RR] Corner Radius | 0.102 mm |

| [RR] Corner Radius | .004 in |

| [RL] Corner Radius | 0.102 mm |

| [RL] Corner Radius | .004 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Grades

WU10PT

An advanced PVD-TiAlN coating over a very deformation-resistant unalloyed carbide substrate. The WU10PT™ grade’s new and improved coating enables speeds to be increased by 50–100%. The WU10PT grade is ideal for finishing to general machining of most workpiece materials at higher speeds. Excellent for machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys under stable conditions. It also performs well machining hardened and short chipping materials.

Features and benefits

- Positive chipbreaker lowers cutting forces

- First choice for steel and stainless steel

- Provides excellent surface finish

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use