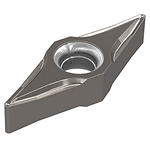

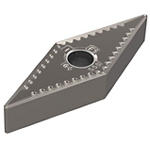

V Style Inserts

V-style inserts, also known as diamond-shaped inserts, or diamond 35° rhombic inserts, are versatile cutting tools widely used in turning. They are engineered with a pointed tip and two cutting edges. V-style carbide inserts offer efficient chip control and are available in a variety of chipbreaker styles, grades, and insert geometries. WIDIA V-style inserts are indispensable tools for your machining operations.

- P Steel (78)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(78)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(78)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(78)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(78)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(78)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(78)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(78)

- M Stainless Steel (41)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(41)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(41)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(41)

- K Cast Iron (35)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(35)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(35)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(35)

- N Non-Ferrous Materials (15)

- N1Wrought Aluminum (14)

- N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2%(14)

- N4Copper, Brass, Zinc-based on machinability index range of 70-100 (15)

- S High-Temp Alloys (56)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(56)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(56)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(56)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(45)

- CN (5)

- DE (51)

- GB (9)

- IN (20)

- SG (26)

- US (41)

- Heavily Interrupted Cut (42)

- Lightly Interrupted Cut (69)

- Smooth Cut (89)

- 2.0 (49)

- 4.0 (77)

- 0.1 mm(5)

- 0.2 mm(7)

- 0.4 mm(43)

- 0.8 mm(59)

- 1.2 mm(12)

- THM (4)

- TN10U (2)

- TN15U (1)

- TN2000 (6)

- TN4000 (4)

- WK05CT (1)

- WK15CT (2)

- WK20CT (8)

- WM15CT (4)

- WM25CT (11)

- WM35CT (1)

- WP15CT (15)

- WP25CT (18)

- WP35CT (6)

- WS10PT (17)

- WS25PT (7)

- WU10HT (10)

- WU10PT (4)

- WU25PT (5)

- 6.35 mm(5)

- 7.15 mm(12)

- 9.525 mm(96)

- 12.7 mm(13)

- 11.071 mm(5)

- 12.45 mm(2)

- 12.455 mm(10)

- 16.606 mm(96)

- 22.142 mm(13)

- 04 (6)

- FF (4)

- FP (15)

- FS (9)

- ML (6)

- MP (5)

- MR (3)

- MS (13)

- RH (7)

- UF (6)

- UR (15)

- G (16)

- M (110)