Reach the Next Level in High-Feed Milling

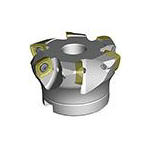

The new VXF™ series combines the best features of round and square inserts to boost metal removal rates, achieve the next level of high-feed milling, and make it the first choice for deep cavities.

The 16.5º angle and special insert geometry reduce deflection and vibrations while the axial and radial facets result in a smooth wall and floor finish.

With two insert geometries available, -MM is the best fit for pocketing and profiling for soft, stainless steel, high-temp alloys, and -MH offers stronger edge protection for heavy roughing jobs for P3 and P4 steel materials.

VXF high-feel mills master demanding workpiece shapes in up to 9 different machining operations and 5 material types, making it a versatile solution for various industries.