Produit similaire à:

Vision Plus™ • Series 7S7R • Radius • Cylindrical Shank • Inch

Series 7S7R • Vision Plus™

Numéro de matériel3116105

Ref. ISO CatalogueTM7S7R13006ARef. ANSI CatalogueTM7S7R13006A

- P Acier

- M Acier inoxydable

- K Fonte

- S Alliages hautes températures

- H Matériaux trempés

Ramping : Ébauche

Rainurage : Bout plat

Style de bec : Rayon de bec

Fraisage de côté/avec épaulement : Bout plat

Angle d'hélice : 45°

Dimensions de l'outil : Configuration des goujures : X (variable)

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 3116105 |

| Ref. ISO Catalogue | TM7S7R13006A |

| Ref. ANSI Catalogue | TM7S7R13006A |

| Nuance | ALTIN-MT |

| Style adaptateur du côté machine | Straight-Cylindrical |

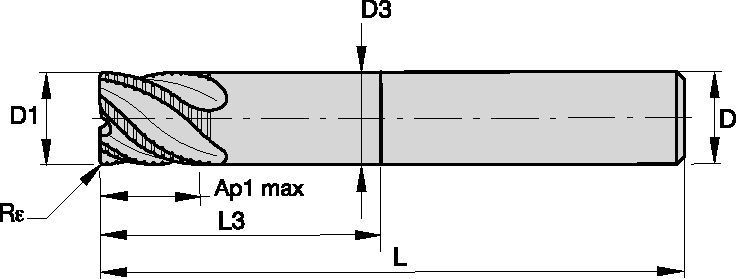

| [D3] Diamètre de la partie cylindrique du corps | 11.938 mm |

| [D3] Diamètre de la partie cylindrique du corps | 0.47 in |

| [L3] Longueur exploitable | 49.53 mm |

| [L3] Longueur exploitable | 1.95 in |

| [Re] Rayon de bec | 1.016 mm |

| [Re] Rayon de bec | 0.04 in |

| [Z] Nombre de goujures | 4 |

| [D1] Diamètre effectif de coupe | 12.7 mm |

| [D1] Diamètre effectif de coupe | 0.5 in |

| [D] Adaptateur / Queue / Diamètre d’alésage | 15.875 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | 0.625 in |

| [AP1MAX] 1re profondeur de coupe maximale | 12.7 mm |

| [AP1MAX] 1re profondeur de coupe maximale | 0.5 in |

| [L] Longueur totale | 127 mm |

| [L] Longueur totale | 5 in |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Alliages hautes températures

- Matériaux trempés

Uses and application

Ramping : Ébauche

Rainurage : Bout plat

Style de bec : Rayon de bec

Fraisage de côté/avec épaulement : Bout plat

Angle d'hélice : 45°

Dimensions de l'outil : Configuration des goujures : X (variable)

Features and benefits

- Center cutting.

- Flat shallow profile.

- Standard items listed. Additional styles and coatings made-to-order.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Données d'application

Series 7S7R • Vision Plus

|  |  | |||||||||||||||

| Fraisage en bout (A) | AlTiN | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||||

| A | B | Vitesse de coupe | Vitesse de coupe | ||||||||||||||

| frac. | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||

| Groupe Matières | ap | ae | ap | Mini | Maxi | dec. | .1563 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.000 | ||

| P | 3 | 0.8 x D | 0.5 x D | 0.75 x D | 390 | – | 520 | IPT | .0009 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 4 | 0.8 x D | 0.4 x D | 0.5 x D | 300 | – | 490 | IPT | .0008 | .0010 | .0014 | .0017 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| 5 | 0.8 x D | 0.5 x D | 0.75 x D | 200 | – | 330 | IPT | .0007 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| 6 | 0.8 x D | 0.4 x D | 0.5 x D | 160 | – | 250 | IPT | .0006 | .0008 | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| M | 1 | 0.8 x D | 0.5 x D | 0.75 x D | 300 | – | 380 | IPT | .0009 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | 0.8 x D | 0.4XD | 0.75 x D | 200 | – | 260 | IPT | .0007 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| 3 | 0.8 x D | 0.4 x D | 0.75 x D | 200 | – | 230 | IPT | .0006 | .0008 | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| K | 1 | 0.8 x D | 0.5 x D | 0.75 x D | 390 | – | 490 | IPT | .0011 | .0013 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 2 | 0.8 x D | 0.5 x D | 0.75 x D | 360 | – | 460 | IPT | .0009 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 3 | 0.8 x D | 0.4 x D | 0.75 x D | 360 | – | 430 | IPT | .0007 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| S | 1 | 0.8 x D | 0.4 x D | 0.75 x D | 160 | – | 300 | IPT | .0009 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | 0.8 x D | 0.4 x D | 0.75 x D | 80 | – | 130 | IPT | .0005 | .0006 | .0008 | .0010 | .0012 | .0015 | .0018 | .0021 | .0024 | |

| 3 | 0.8 x D | 0.25 x D | 0.3 x D | 80 | – | 130 | IPT | .0005 | .0006 | .0008 | .0010 | .0012 | .0015 | .0018 | .0021 | .0024 | |

| 4 | 0.8 x D | 0.3 x D | 0.5 x D | 160 | – | 200 | IPT | .0006 | .0008 | .0011 | .0014 | .0017 | .0021 | .0025 | .0028 | .0033 | |

| H | 1 | 0.8 x D | 0.5 x D | 0.5 x D | 260 | – | 460 | IPT | .0008 | .0010 | .0014 | .0017 | .0020 | .0026 | .0030 | .0034 | .0039 |

| 2 | 0.8 x D | 0.2 x D | 0.3 x D | 230 | – | 390 | IPT | .0006 | .0008 | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| 3 | 0.8 x D | 0.15 x D | 0.2 x D | 200 | – | 300 | IPT | .0005 | .0006 | .0008 | .0010 | .0012 | .0015 | .0018 | .0021 | .0024 | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data