Product Similar To:

4946 • High-Performance Roughing • Metric

4946 • High-Performance Roughing • Metric

Material Number6127284

ISO Catalog ID4946200NDL20ANSI Catalog ID4946200NDL20

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

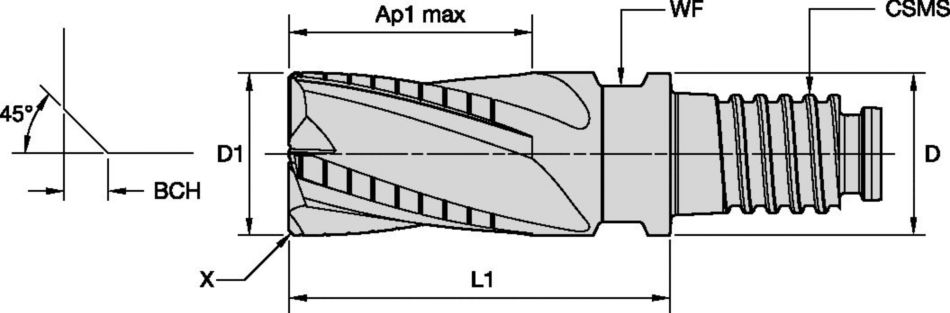

Tool Dimensions: Flute Configuration: X (variable)

Corner Style: Corner Chamfer

Helix Angle: 20°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6127284 |

| ISO Catalog ID | 4946200NDL20 |

| ANSI Catalog ID | 4946200NDL20 |

| Grade | WP15PE |

| Adapter Style Machine Side | DUO-LOCK |

| [D1] Effective Cutting Diameter | 20 mm |

| [D1] Effective Cutting Diameter | .7874 in |

| [D] Adapter / Shank / Bore Diameter | 19.3 mm |

| [D] Adapter / Shank / Bore Diameter | .7598 in |

| [AP1MAX] 1st Maximum Cutting Depth | 30 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.181 in |

| [L1] Gage Length | 45 mm |

| [L1] Gage Length | 1.771 in |

| [CSMS] System Size Machine Side | DL20 |

| [WF] Width of Flat | 16 mm |

| [WF] Width of Flat | .6299 in |

| [BCH] Corner Chamfer Width | 0.5 mm |

| [BCH] Corner Chamfer Width | .0197 in |

| [Z] Number of Flutes | 4 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: X (variable)

Corner Style: Corner Chamfer

Helix Angle: 20°

Features and benefits

- Center cutting.

- Cord profile reduces machine power consumption.

- Standard items listed. Additional styles and coatings made-to-order.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

4946 • High-Performance Roughing • Metric

|  |  | ||||||||||||||||||

| Side Milling (A) and Slotting (B) | short | medium | long | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||||||

| A | B | adapter reach | D1 | |||||||||||||||||

| WP15PE | WP15PE | WP15PE | ||||||||||||||||||

| Cutting Speed | Cutting Speed | Cutting Speed | ||||||||||||||||||

| Material | ap | ae | ap | Min | Max | Min | Max | Min | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | 32,0 | ||||

| P | 0 | 1,5 x D | 0,5 x D | 1 x D | 120 | – | 160 | 108 | – | 144 | 108 | – | 144 | fz | 0,061 | 0,070 | 0,086 | 0,097 | 0,105 | 0,106 |

| 1 | 1,5 x D | 0,5 x D | 1 x D | 120 | – | 160 | 108 | – | 144 | 108 | – | 144 | fz | 0,061 | 0,070 | 0,086 | 0,097 | 0,105 | 0,106 | |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 112 | – | 152 | 100,8 | – | 136,8 | 100,8 | – | 136,8 | fz | 0,061 | 0,070 | 0,086 | 0,097 | 0,105 | 0,106 | |

| 3 | 1,5 x D | 0,4 x D | 0,75 x D | 96 | – | 128 | 86,4 | – | 115,2 | 86,4 | – | 115,2 | fz | 0,051 | 0,060 | 0,074 | 0,086 | 0,097 | 0,105 | |

| 4 | 1,5 x D | 0,3 x D | 0,30 x D | 72 | – | 120 | 64,8 | – | 108 | 64,8 | – | 108 | fz | 0,046 | 0,053 | 0,065 | 0,075 | 0,083 | 0,087 | |

| 5 | 1,5 x D | 0,4 x D | 0,75 x D | 48 | – | 80 | 40,8 | – | 68 | 38,4 | – | 64 | fz | 0,041 | 0,048 | 0,059 | 0,069 | 0,077 | 0,084 | |

| M | 1 | 1,5 x D | 0,4 x D | 0,75 x D | 72 | – | 92 | 57,6 | – | 73,6 | 50,4 | – | 64,4 | fz | 0,051 | 0,060 | 0,074 | 0,086 | 0,097 | 0,105 |

| 2 | 1,5 x D | 0,4 x D | 0,75 x D | 48 | – | 64 | 38,4 | – | 51,2 | 33,6 | – | 44,8 | fz | 0,041 | 0,048 | 0,059 | 0,069 | 0,077 | 0,084 | |

| 3 | 1,5 x D | 0,4 x D | 0,75 x D | 48 | – | 56 | 38,4 | – | 44,8 | 33,6 | – | 39,2 | fz | 0,034 | 0,040 | 0,048 | 0,055 | 0,060 | 0,062 | |

| K | 1 | 1,5 x D | 0,5 x D | 1 x D | 96 | – | 120 | 86,4 | – | 108 | 86,4 | – | 108 | fz | 0,061 | 0,070 | 0,086 | 0,097 | 0,105 | 0,106 |

| 2 | 1,5 x D | 0,4 x D | 1 x D | 88 | – | 112 | 79,2 | – | 100,8 | 79,2 | – | 100,8 | fz | 0,051 | 0,060 | 0,074 | 0,086 | 0,097 | 0,105 | |

| 3 | 1,5 x D | 0,4 x D | 1 x D | 88 | – | 104 | 79,2 | – | 93,6 | 79,2 | – | 93,6 | fz | 0,041 | 0,048 | 0,059 | 0,069 | 0,077 | 0,084 | |

| S | 1 | 1,5 x D | 0,4 x D | 0,75 x D | 40 | – | 72 | 32 | – | 57,6 | 24 | – | 43,2 | fz | 0,051 | 0,060 | 0,074 | 0,086 | 0,097 | 0,105 |

| 3 | 1,5 x D | 0,4 x D | 0,75 x D | 20 | – | 32 | 16 | – | 25,6 | 12 | – | 19,2 | fz | 0,027 | 0,032 | 0,039 | 0,046 | 0,052 | 0,057 | |

| H | 1 | 1,5 x D | 0,3 x D | 0,30 x D | 64 | – | 112 | 51,2 | – | 89,6 | 38,4 | – | 67,2 | fz | 0,046 | 0,053 | 0,065 | 0,075 | 0,083 | 0,087 |

I have read and accepted the Terms & Conditions of use