Product Similar To :

VDS201F / VDS401F • WU25PD • F-Shank • 3 x D

VariDrill™ • Steel, Stainless Steel, Cast Iron, Aluminum, and High-Temp Alloys • 3 x D

Material Number4140521

ISO Catalog IDVDS401F12100ANSI Catalog IDVDS401F12100

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Drilling

Drilling - Through Coolant

Flood Coolant: Drilling

Shank - Cylindrical Whistle Notch 2°

Helix Angle: 30°

38550

38563

Drilling Depth: 3x

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4140521 |

| ISO Catalog ID | VDS401F12100 |

| ANSI Catalog ID | VDS401F12100 |

| Grade | WU25PD |

| Adapter Style Machine Side | Whistle Notch 2 CylindricalEnd |

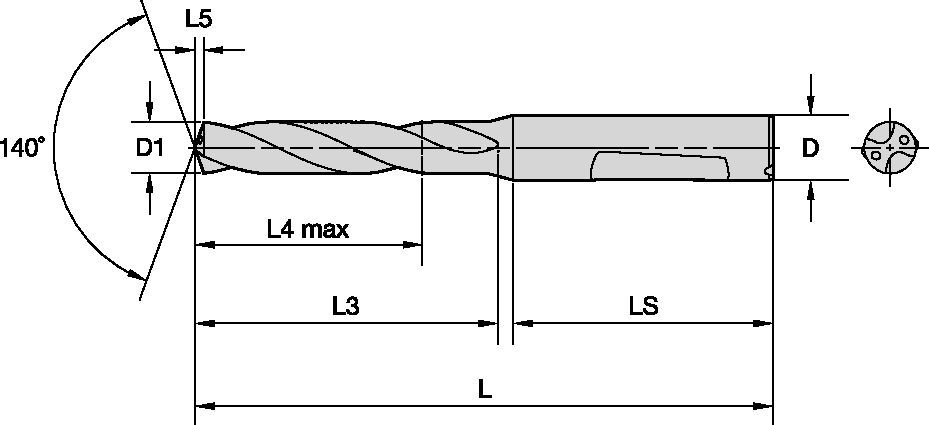

| [D1] Drill Diameter M | 12.1 mm |

| [D1] Drill Diameter M | 0.4764 in |

| [L4] Maximum Drilling Depth | 43 mm |

| [L4] Maximum Drilling Depth | 1.69 in |

| [L3] Flute Length | 60 mm |

| [L3] Flute Length | 2.36 in |

| [L5] Drill Point Length | 2.08 mm |

| [L5] Drill Point Length | 0.082 in |

| [L] Overall Length | 107 mm |

| [L] Overall Length | 4.21 in |

| [LS] Shank Length | 45 mm |

| [LS] Shank Length | 1.77 in |

| [D] Adapter / Shank / Bore Diameter | 14 mm |

| [D] Adapter / Shank / Bore Diameter | 0.5512 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Uses and application

Drilling

Drilling - Through Coolant

Flood Coolant: Drilling

Shank - Cylindrical Whistle Notch 2°

Helix Angle: 30°

38550

38563

Drilling Depth: 3x

Grades

WU25PD

Composition: With a multilayered PVD TiN-TiAlN coating and a high-quality, sub-micron, carbide substrate, this grade gives a high level of wear resistance at medium to high cutting speeds.

Application: First choice for high reliability in all materials. This grade should be used at medium to high speeds and feeds. It is a general-purpose grade that performs very well for alloyed and high-alloy steel and cast iron, but can also be used with excellent performance in all other material groups.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use