Product Similar To:

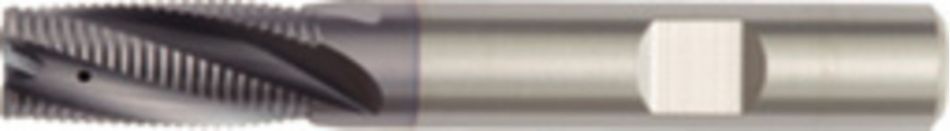

Roughers • Series 49H6 • Chamfer • Internal Coolant • Metric

Series 49H6

Material Number1657264

ISO Catalog ID49H610004RWANSI Catalog ID49H610004RW

Ramping: Blank

Slotting: Square End

Drilling - Through Coolant

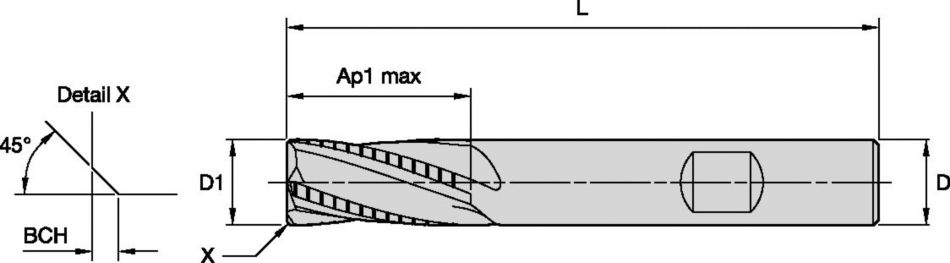

Corner Style: Corner Chamfer

Side Milling/Shoulder Milling: Square End

Helix Angle: 20°

Tool Dimensions: Flute Configuration: X (variable)

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1657264 |

| ISO Catalog ID | 49H610004RW |

| ANSI Catalog ID | 49H610004RW |

| Grade | WP15PE |

| Adapter Style Machine Side | Weldon |

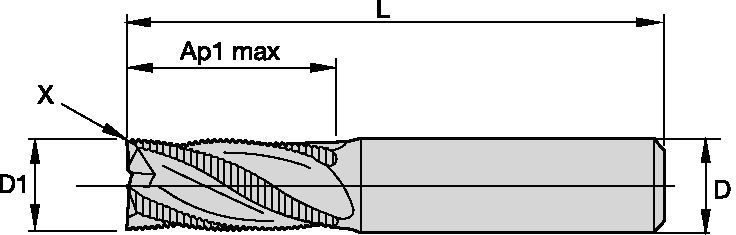

| [D1] Effective Cutting Diameter | 10 mm |

| [D1] Effective Cutting Diameter | .394 in |

| [D] Adapter / Shank / Bore Diameter | 10 mm |

| [D] Adapter / Shank / Bore Diameter | .3937 in |

| [AP1MAX] 1st Maximum Cutting Depth | 22 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .866 in |

| [L] Overall Length | 72 mm |

| [L] Overall Length | 2.835 in |

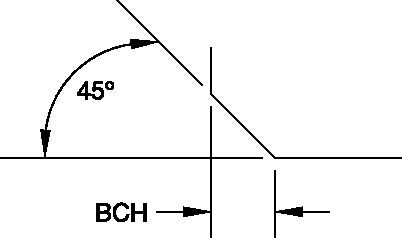

| [BCH] Corner Chamfer Width | 0.5 mm |

| [BCH] Corner Chamfer Width | .0197 in |

| [Z] Number of Flutes | 4 |

Uses and application

Ramping: Blank

Slotting: Square End

Drilling - Through Coolant

Corner Style: Corner Chamfer

Side Milling/Shoulder Milling: Square End

Helix Angle: 20°

Tool Dimensions: Flute Configuration: X (variable)

Grades

WP15PE

Coated carbide grade with thick PVD coating and optimized chemistry and process for increased wear resistance. Outstanding protection in milling of steels to mitigate crater, DOCN (depth-of-cut notching), and flank wear. Excellent performance up to 52 HRC.

Features and benefits

- Centre cutting.

- Fine pitch.

- TIALN-LW = Multi-Layer.

- TIALN-RW = Mono-Layer.

- Standard items listed. Additional styles and coatings made-to-order.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

Series 49H6

|  |  | |||||||||||||

| Side Milling (A) and Slotting (B) | WP15PE/TiAlN | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||||||||

| A | B | Cutting Speed | D1 | ||||||||||||

| Material | ap | ae | ap | Min | Max | mm | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | ||

| P | 0 | 1,5 x D | 0,5 x D | 1 x D | 150 | – | 200 | fz | 0,048 | 0,058 | 0,066 | 0,074 | 0,081 | 0,086 | 0,091 |

| 1 | 1,5 x D | 0,5 x D | 1 x D | 150 | – | 200 | fz | 0,048 | 0,058 | 0,066 | 0,074 | 0,081 | 0,086 | 0,091 | |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 140 | – | 190 | fz | 0,048 | 0,058 | 0,066 | 0,074 | 0,081 | 0,086 | 0,091 | |

| 3 | 1,0 x D | 0,4 x D | 0,75 x D | 120 | – | 160 | fz | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 | |

| 4 | 1,0 x D | 0,3 x D | 0,5 x D | 90 | – | 150 | fz | 0,036 | 0,043 | 0,050 | 0,056 | 0,061 | 0,066 | 0,070 | |

| 5 | 1,0 x D | 0,4 x D | 0,75 x D | 60 | – | 100 | fz | 0,032 | 0,039 | 0,045 | 0,051 | 0,056 | 0,060 | 0,065 | |

| M | 1 | 1,0 x D | 0,4 x D | 0,75 x D | 90 | – | 115 | fz | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 |

| 2 | 1,0 x D | 0,4 x D | 0,75 x D | 60 | – | 80 | fz | 0,032 | 0,039 | 0,045 | 0,051 | 0,056 | 0,060 | 0,065 | |

| 3 | 1,0 x D | 0,4 x D | 0,75 x D | 60 | – | 70 | fz | 0,027 | 0,032 | 0,037 | 0,042 | 0,046 | 0,049 | 0,052 | |

| K | 1 | 1,5 x D | 0,5 x D | 1 x D | 120 | – | 150 | fz | 0,048 | 0,058 | 0,066 | 0,074 | 0,081 | 0,086 | 0,091 |

| 2 | 1,5 x D | 0,4 x D | 1 x D | 110 | – | 140 | fz | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 | |

| 3 | 1,5 x D | 0,4 x D | 1 x D | 110 | – | 130 | fz | 0,032 | 0,039 | 0,045 | 0,051 | 0,056 | 0,060 | 0,065 | |

| S | 1 | 1,5 x D | 0,5 x D | 0,75 x D | 50 | – | 90 | fz | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 |

| 3 | 1,5 x D | 0,5 x D | 0,75 x D | 25 | – | 40 | fz | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,054 | |

| H | 1 | 1,0 x D | 0,3 x D | 0,5 x D | 80 | – | 140 | fz | 0,036 | 0,043 | 0,050 | 0,056 | 0,061 | 0,066 | 0,070 |

I have read and accepted the Terms & Conditions of use