Product Similar To:

TOP DRILL™ Modular X • 12 x D • Flanged Round Shank • Inch

TDMX • 12 x D • Flanged Round Shank • Inch

Material Number6681003

ISO Catalog IDTDMX0827R12SF100ANSI Catalog IDTDMX0827R12SF100

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: Stacked Plates

Drilling - Through Coolant

Shank - Cylindrical Plain

38513

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

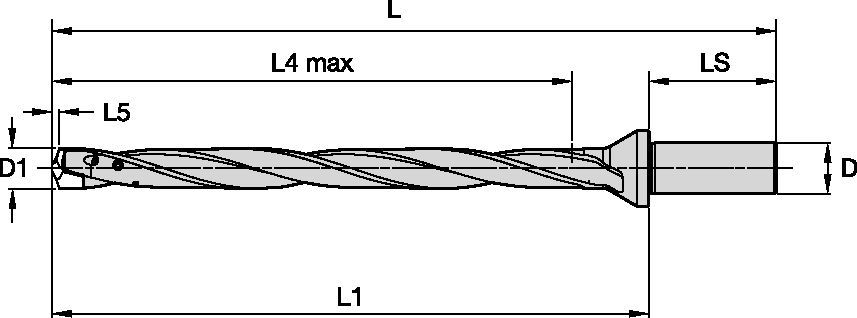

| Material Number | 6681003 |

| ISO Catalog ID | TDMX0827R12SF100 |

| ANSI Catalog ID | TDMX0827R12SF100 |

| [SSC] Insert Seat Size | F |

| [D1] Drill Diameter M | 21 mm |

| [D1] Drill Diameter M | .8268 in |

| [D1MAX] Drill Diameter Maximum | 21.999 mm |

| [D1MAX] Drill Diameter Maximum | .8661 in |

| [LS] Shank Length | 56 mm |

| [LS] Shank Length | 2.204 in |

| [D] Adapter / Shank / Bore Diameter | 25.4 mm |

| [D] Adapter / Shank / Bore Diameter | 1 in |

| [L] Overall Length | 358 mm |

| [L] Overall Length | 14.094 in |

| [L1] Insert Gage Length | 302 mm |

| [L1] Insert Gage Length | 11.889 in |

| [L4] Maximum Drilling Depth | 264 mm |

| [L4] Maximum Drilling Depth | 10.393 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Uses and application

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: Stacked Plates

Drilling - Through Coolant

Shank - Cylindrical Plain

38513

Drilling: Cross-Hole Drilling

Features and benefits

- Flanged shank with a single flat for maximum rigidity

- Internal coolant channels

- Front clamping. No needs to disassemble the body from the tool holder to change the insert

- Highly engineered pocket seat design for high stability even in critical operations

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| Metric | ||

| tolerance | ||

| Insert Type | TDMX….PK; MS; FP | TDMX…FPE |

| D1 | Tolerance k7 | Tolerance s7 |

| 16-18 | .+0,001/+0.019 | .+0.028/+0.046 |

| >18-30 | .+0,002/+0,023 | .+0,035/+0,056 |

| >30-40 | .+0,002/+0,027 | .+0,043/+0,068 |

| Inch | ||

| tolerance | ||

| Insert Type | TDMX….PK | |

Application Data

Application Data • PK(M) • WP40PD • Metric

|  |  | ||||||||

| Cutting Speed | ||||||||||

| Range | Recommended Feed Rate (f) by Diameter | |||||||||

| Material | Min | Starting Value | Max | Tool Diameter | 16,0 | 20,0 | 25,0 | 32,0 | 40,0 | |

| P | 1 | 90 | 125 | 170 | mm/r | 0,19–0,45 | 0,25–0,48 | 0,25–0,52 | 0,28–0,57 | 0,29–0,60 |

| 2 | 105 | 140 | 180 | mm/r | 0,23–0,46 | 0,28–0,50 | 0,30–0,52 | 0,33–0,57 | 0,35–0,60 | |

| 3 | 50 | 75 | 100 | mm/r | 0,23–0,46 | 0,28–0,50 | 0,30–0,52 | 0,33–0,57 | 0,35–0,60 | |

| 4 | 50 | 75 | 100 | mm/r | 0,19–0,45 | 0,22–0,48 | 0,25–0,50 | 0,28–0,55 | 0,29–0,58 | |

| 5 | 50 | 65 | 80 | mm/r | 0,16–0,32 | 0,18–0,36 | 0,22–0,42 | 0,24–0,46 | 0,25–0,48 | |

| 6 | 50 | 65 | 80 | mm/r | 0,16–0,32 | 0,18–0,36 | 0,22–0,42 | 0,24–0,46 | 0,25–0,48 | |

| M | 1 | 40 | 80 | 110 | mm/r | 0,11–0,26 | 0,13–0,28 | 0,13–0,32 | 0,14–0,35 | 0,15–0,37 |

| 2 | 35 | 55 | 75 | mm/r | 0,11–0,26 | 0,13–0,28 | 0,13–0,32 | 0,14–0,35 | 0,15–0,37 | |

| 3 | 20 | 35 | 50 | mm/r | 0,11–0,26 | 0,13–0,28 | 0,13–0,32 | 0,14–0,35 | 0,15–0,37 | |

| K | 1 | 60 | 95 | 170 | mm/r | 0,25–0,48 | 0,28–0,52 | 0,32–0,56 | 0,35–0,62 | 0,37–0,65 |

| 2 | 60 | 75 | 90 | mm/r | 0,25–0,48 | 0,28–0,52 | 0,32–0,56 | 0,35–0,62 | 0,37–0,65 | |

| 3 | 40 | 65 | 90 | mm/r | 0,21–0,44 | 0,23–0,48 | 0,25–0,50 | 0,28–0,55 | 0,29–0,58 | |

Application Data • MS(M) • WM15PD • Metric

| Material |  |  | ||||||||

| Cutting Speed | ||||||||||

| Range | Recommended Feed Rate (f) by Diameter | |||||||||

| – | – | Min | Starting Value | Max | Tool Diameter | 16,0 | 20,0 | 25,0 | 32,0 | 40,0 |

| M | 1 | 40 | 80 | 110 | mm/r | 0,11 – 0,26 | 0,13 – 0,28 | 0,13 – 0,32 | 0,14 – 0,35 | 0,15 – 0,37 |

| 2 | 35 | 55 | 75 | mm/r | 0,11 – 0,26 | 0,13 – 0,28 | 0,13 – 0,32 | 0,14 – 0,35 | 0,15 – 0,37 | |

| 3 | 20 | 35 | 50 | mm/r | 0,11 – 0,26 | 0,13 – 0,28 | 0,13 – 0,32 | 0,14 – 0,35 | 0,15 – 0,37 | |

| K | 1 | 90 | 135 | 175 | mm/r | 0,19 – 0,25 | 0,22 – 0,29 | 0,29 – 0,38 | 0,32 – 0,43 | 0,33 – 0,50 |

| 2 | 80 | 120 | 140 | mm/r | 0,19 – 0,25 | 0,22 – 0,29 | 0,29 – 0,38 | 0,32 – 0,43 | 0,33 – 0,50 | |

| 3 | 70 | 110 | 125 | mm/r | 0,18 – 0,26 | 0,21 – 0,29 | 0,23 – 0,37 | 0,25 – 0,42 | 0,27 – 0,46 | |

| N | 1 | 90 | 155 | 220 | mm/r | 0,25 – 0,50 | 0,28 – 0,56 | 0,32 – 0,63 | 0,32 – 0,70 | 0,32 – 0,70 |

| 2 | 90 | 155 | 220 | mm/r | 0,25 – 0,50 | 0,28 – 0,56 | 0,32 – 0,63 | 0,32 – 0,70 | 0,32 – 0,70 | |

| 3 | 80 | 120 | 160 | mm/r | 0,25 – 0,50 | 0,28 – 0,56 | 0,32 – 0,63 | 0,32 – 0,70 | 0,32 – 0,70 | |

| 4 | 90 | 155 | 220 | mm/r | 0,25 – 0,50 | 0,28 – 0,56 | 0,32 – 0,63 | 0,32 – 0,70 | 0,32 – 0,70 | |

| 5 | 160 | 200 | 240 | mm/r | 0,25 – 0,50 | 0,28 – 0,56 | 0,32 – 0,63 | 0,32 – 0,70 | 0,32 – 0,70 | |

| 6 | 160 | 200 | 240 | mm/r | 0,25 – 0,50 | 0,28 – 0,56 | 0,32 – 0,63 | 0,32 – 0,70 | 0,32 – 0,70 | |

| S | 1 | 20 | 40 | 60 | mm/r | 0,07 – 0,12 | 0,09 – 0,14 | 0,11 – 0,17 | 0,13 – 0,20 | 0,16 – 0,25 |

| 2 | 15 | 30 | 45 | mm/r | 0,07 – 0,12 | 0,09 – 0,14 | 0,11 – 0,17 | 0,13 – 0,20 | 0,16 – 0,25 | |

| 3 | 15 | 30 | 45 | mm/r | 0,07 – 0,12 | 0,09 – 0,14 | 0,11 – 0,17 | 0,13 – 0,20 | 0,16 – 0,25 | |

| 4 | 10 | 25 | 40 | mm/r | 0,07 – 0,12 | 0,13 – 0,20 | 0,16 – 0,25 | 0,18 – 0,28 | 0,21 – 0,31 | |

Application Data • MS(M) • WM15PD • Inch

|  | |||||||||

| Cutting Speed | ||||||||||

| Range | Recommended Feed Rate (f) by Diameter | |||||||||

| Material | – | Min | Starting Value | Max | Tool Diameter | 0.630 | 0.787 | 1.000 | 1.260 | 1.575 |

| M | 1 | 131 | 262 | 361 | IPR | .004 – .010 | .005 – .012 | .005 – .013 | .006 – .014 | .006 – .015 |

| 2 | 115 | 180 | 246 | IPR | .004 – .010 | .005 – .012 | .005 – .013 | .006 – .014 | .006 – .015 | |

| 3 | 66 | 115 | 164 | IPR | .004 – .010 | .005 – .012 | .005 – .013 | .006 – .014 | .006 – .015 | |

| K | 1 | 295 | 443 | 574 | IPR | .007 – .010 | .009 – .019 | .011 – .015 | .013 – .017 | .013 – .020 |

| 2 | 262 | 394 | 459 | IPR | .007 – .010 | .009 – .019 | .011 – .015 | .013 – .017 | .013 – .020 | |

| 3 | 230 | 361 | 410 | IPR | .007 – .010 | .009 – .019 | .009 – .015 | .010 – .017 | .011 – .020 | |

| N | 1 | 295 | 508 | 722 | IPR | .010 – .020 | .011 – .022 | .013 – .025 | .013 – .028 | .013 – .028 |

| 2 | 295 | 508 | 722 | IPR | .010 – .020 | .011 – .022 | .013 – .025 | .013 – .028 | .013 – .028 | |

| 3 | 262 | 394 | 525 | IPR | .010 – .020 | .011 – .022 | .013 – .025 | .013 – .028 | .013 – .028 | |

| 4 | 295 | 508 | 722 | IPR | .010 – .020 | .011 – .022 | .013 – .025 | .013 – .028 | .013 – .028 | |

| 5 | 525 | 656 | 787 | IPR | .010 – .020 | .011 – .022 | .013 – .025 | .013 – .028 | .013 – .028 | |

| 6 | 525 | 656 | 787 | IPR | .010 – .020 | .011 – .022 | .013 – .025 | .013 – .028 | .013 – .028 | |

| S | 1 | 66 | 131 | 197 | IPR | .003 – .005 | .004 – .006 | .004 – .007 | .005 – .008 | .006 – .010 |

| 2 | 49 | 98 | 148 | IPR | .003 – .005 | .004 – .006 | .004 – .007 | .005 – .008 | .006 – .010 | |

| 3 | 49 | 98 | 148 | IPR | .003 – .005 | .004 – .006 | .004 – .007 | .005 – .008 | .006 – .010 | |

| 4 | 33 | 82 | 131 | IPR | .003 – .005 | .005 – .008 | .006 – .010 | .007 – .011 | .008 – .012 | |

I have read and accepted the Terms & Conditions of use