Produkt podobny do:

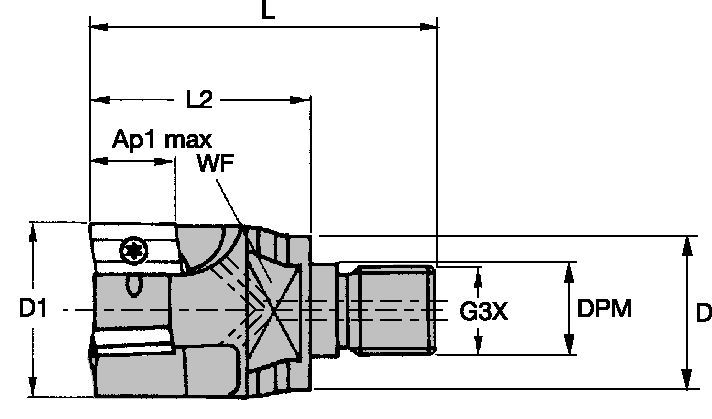

M680+ • Z chwytem gwintowanym • Metryczne

Korpusy narzędzi M680+

Nr materiału2223036

Nr katalogowy ISO12396931400Nr katalogowy ANSI12396931400

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Face Milling

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Shank - Screw-On

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Podsumowanie

- Parametry skrawania

- Do pobrania

- Pasujace produkty - strona przedmiotu obrabianego

- Części zamienne

- Opinia

- Q&A

| Nr materiału | 2223036 |

| Nr katalogowy ISO | 12396931400 |

| Nr katalogowy ANSI | 12396931400 |

| Grade | W |

| [D1] Effective Cutting Diameter | 25 mm |

| [D1] Effective Cutting Diameter | .9843 in |

| [D] Adapter / Shank / Bore Diameter | 25 mm |

| [D] Adapter / Shank / Bore Diameter | .9843 in |

| [DPM] Pilot Diameter Machine Side | 12.5 mm |

| [DPM] Pilot Diameter Machine Side | .4921 in |

| [G3X] Connection Thread Size External | M12 |

| [L] Overall Length | 52 mm |

| [L] Overall Length | 2.047 in |

| [L2] Head Length | 30 mm |

| [L2] Head Length | 1.181 in |

| [WF] Width of Flat | 19 mm |

| [WF] Width of Flat | .748 in |

| [AP1MAX] 1st Maximum Cutting Depth | 9.5 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .374 in |

| Number of Inserts | 3 |

| Max RPM | 9500 |

| Coolant Supply | Y |

| Weight Kilograms | 0.2 |

Materiały przedmiotu obrabianego

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Zastosowania

Face Milling

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Shank - Screw-On

Właściwości i zalety

- Frez walcowo-czołowy ogólnego zastosowania.

- Mała, ale mocna płytka.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Dobór płytek

Poradnik doboru płytek

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | XPHT-GE | WP40PM | XPHT.. | WP40PM | XPHT.. | WP40PM |

| P3–P4 | XPHT-GE | TN6540 | XPHT.. | WP40PM | XPHT.. | WP40PM |

| P5–P6 | XPHT-GE | TN6540 | XPHT.. | WP40PM | XPHT.. | WP40PM |

| M1–M2 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| M3 | XPHT-GE | TN7535 | XPHT.. | WP40PM | XPHT-MR | TN7535 |

| K1–K2 | XPHT-GE | TN6510 | XPHT.. | TN6520 | XPHT-MR | WK15CM |

| K3 | XPHT-GE | TN6510 | XPHT.. | TN7535 | XPHT-MR | WK15CM |

| N1–N2 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 |

| N3 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 |

| S1–S2 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| S3 | XPHT-GE | WS30PM | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| S4 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| H1 | XPHT-GE | WS30PM | XPHT.. | TN6540 | XPHT-MR | TN6540 |

Posuwy

Zalecane startowe wartości posuwu [mm]

| Geometria płytki | Zalecany posuw na ostrze (fz) zależny od % szerokości frezowania (ae) | Geometria płytki | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| XPHT-ALP | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | XPHT-ALP |

| XPHT-GE | 0,19 | 0,47 | 0,70 | 0,14 | 0,34 | 0,50 | 0,11 | 0,26 | 0,38 | 0,09 | 0,22 | 0,33 | 0,08 | 0,20 | 0,30 | XPHT-GE |

| XPHT.. | 0,22 | 0,56 | 0,82 | 0,16 | 0,40 | 0,59 | 0,12 | 0,30 | 0,44 | 0,10 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | XPHT.. |

| XPNT.. | 0,22 | 0,56 | 0,82 | 0,16 | 0,40 | 0,59 | 0,12 | 0,30 | 0,44 | 0,10 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | XPNT.. |

| XPHT-MR | 0,23 | 0,59 | 0,92 | 0,17 | 0,43 | 0,66 | 0,13 | 0,32 | 0,50 | 0,11 | 0,28 | 0,43 | 0,10 | 0,25 | 0,40 | XPHT-MR |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

Prędkości

Zalecane wyjściowe wartości prędkości skrawania [m/min]

| Grupa materiałowa | THR | THM-U | TN6501 | TN6502 | TN6510 | TN6520 | TN6525 | TN6540 | |||||||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 |

| 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | |

| K | 1 | 150 | 135 | 120 | 190 | 170 | 150 | – | – | – | – | – | – | 400 | 290 | 215 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 |

| 2 | 185 | 140 | 120 | – | – | – | – | – | – | – | – | – | 350 | 235 | 170 | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | |

| 3 | 105 | 75 | 50 | – | – | – | – | – | – | – | – | – | 280 | 215 | 165 | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | |

| N | 1 | 900 | 600 | 500 | 2000 | 1200 | 1000 | 2000 | 1200 | 1000 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | 1365 | 815 | 665 | 1365 | 815 | 665 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | 800 | 500 | 400 | 800 | 500 | 400 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 35 | 25 | 20 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 30 | 25 |

| 2 | 25 | 20 | 15 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 20 | 15 | 10 | |

| 3 | 50 | 40 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 35 | 25 | |

| 4 | 35 | 25 | 18 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 25 | 20 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Grupa materiałowa | TTM08 | WK15PM | WP35CM | WU20PM | TTI25 | THM | WK15CM | WP40PM | WS30PM | |||||||||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | 360 | 300 | 250 | – | – | – | – | – | – | 295 | 260 | 245 | – | – | – |

| 1 | 230 | 200 | 190 | – | – | – | 455 | 395 | 370 | 330 | 290 | 270 | 360 | 300 | 250 | – | – | – | – | – | – | 295 | 260 | 245 | – | – | – | |

| 2 | 195 | 170 | 140 | – | – | – | 280 | 255 | 230 | 275 | 250 | 200 | 260 | 210 | 180 | – | – | – | – | – | – | 250 | 215 | 180 | – | – | – | |

| 3 | 180 | 150 | 125 | – | – | – | 255 | 230 | 205 | 255 | 220 | 175 | 260 | 210 | 180 | – | – | – | – | – | – | 230 | 195 | 160 | – | – | – | |

| 4 | 160 | 130 | 105 | – | – | – | 190 | 175 | 160 | 225 | 190 | 150 | 220 | 180 | 150 | – | – | – | – | – | – | 205 | 170 | 135 | – | – | – | |

| 5 | – | – | – | – | – | – | 260 | 230 | 210 | 185 | 175 | 150 | 265 | 195 | 165 | – | – | – | – | – | – | 170 | 155 | 135 | – | – | – | |

| 6 | – | – | – | – | – | – | 160 | 135 | 110 | 165 | 130 | 100 | 120 | 90 | 75 | – | – | – | – | – | – | 150 | 115 | 90 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 205 | 185 | 155 | 205 | 180 | 165 | 400 | 260 | 180 | – | – | – | – | – | – | 195 | 170 | 155 | 225 | 200 | 185 |

| 2 | – | – | – | – | – | – | 185 | 160 | 140 | 185 | 160 | 130 | 270 | 170 | 120 | – | – | – | – | – | – | 175 | 150 | 125 | 205 | 180 | 145 | |

| 3 | – | – | – | – | – | – | 145 | 130 | 115 | 140 | 120 | 95 | 265 | 175 | 120 | – | – | – | – | – | – | 130 | 115 | 90 | 155 | 135 | 105 | |

| K | 1 | – | – | – | 400 | 290 | 215 | 295 | 265 | 240 | 250 | 220 | 185 | 185 | 155 | 130 | – | – | – | 420 | 385 | 340 | – | – | – | – | – | – |

| 2 | – | – | – | 350 | 235 | 170 | 235 | 210 | 190 | 200 | 180 | 150 | 150 | 120 | 105 | – | – | – | 335 | 295 | 275 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 215 | 165 | 195 | 175 | 160 | 180 | 150 | 120 | 120 | 105 | 85 | – | – | – | 280 | 250 | 230 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | 795 | 695 | 600 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | 795 | 695 | 600 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 400 | 350 | 300 | – | – | – | 560 | 485 | 420 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 |

| 2 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | |

| 3 | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | |

| 4 | – | – | – | – | – | – | 66 | 50 | 33 | 70 | 50 | 35 | – | – | – | – | – | – | – | – | – | 65 | 50 | 35 | 85 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | – | – | – | 110 | 80 | 70 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use