Product Similar To:

M16 • Weldon® Shank • Metric

Weldon® Shanks

Material Number2021383

ISO Catalog ID12391603800ANSI Catalog ID12391603800

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- .caption

Slotting: Side

Milling - Through Coolant

Shank - Cylindrical Weldon 2 Flat

Slotting: T

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 2021383 |

| ISO Catalog ID | 12391603800 |

| ANSI Catalog ID | 12391603800 |

| Grade | W |

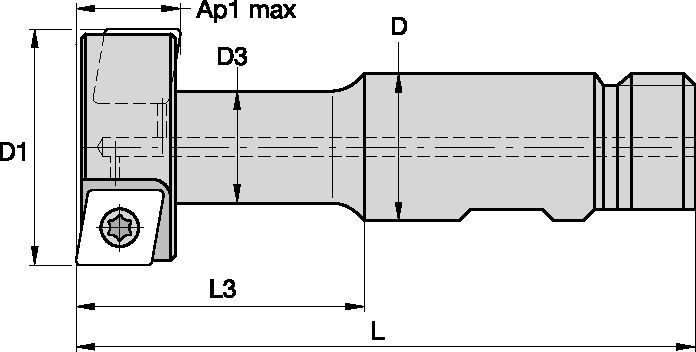

| [D1] Effective Cutting Diameter | 49.875 mm |

| [D1] Effective Cutting Diameter | 1.964 in |

| [D] Adapter / Shank / Bore Diameter | 32 mm |

| [D] Adapter / Shank / Bore Diameter | 1.2598 in |

| [D3] Neck Diameter | 25.07 mm |

| [D3] Neck Diameter | 0.987 in |

| [L] Overall Length | 120 mm |

| [L] Overall Length | 4.724 in |

| [L3] Usable Length | 60 mm |

| [L3] Usable Length | 2.362 in |

| [AP1MAX] 1st Maximum Cutting Depth | 21.85 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.86 in |

| Number of Inserts | 4 |

| [Z] Number of Flutes | 2 |

| Gage Insert | CPNT120408T |

| Coolant Supply | Y |

| Weight Kilograms | 0.68 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- .caption

Uses and application

Slotting: Side

Milling - Through Coolant

Shank - Cylindrical Weldon 2 Flat

Slotting: T

Features and benefits

- T-slot mill.

- Ideal for steel and cast iron machining.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| CPNT06 | 0,12 | 0,29 | 0,46 | 0,09 | 0,21 | 0,33 | 0,07 | 0,16 | 0,25 | 0,06 | 0,14 | 0,22 | 0,05 | 0,13 | 0,20 | CPNT06 |

| CPNT08 | 0,12 | 0,29 | 0,46 | 0,09 | 0,21 | 0,33 | 0,07 | 0,16 | 0,25 | 0,06 | 0,14 | 0,22 | 0,05 | 0,13 | 0,20 | CPNT08 |

| CPNT09 | 0,12 | 0,29 | 0,46 | 0,08 | 0,21 | 0,33 | 0,06 | 0,16 | 0,25 | 0,06 | 0,14 | 0,22 | 0,05 | 0,13 | 0,20 | CPNT09 |

| CPNT12 | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,32 | 0,06 | 0,16 | 0,28 | 0,05 | 0,15 | 0,25 | CPNT12 |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | THM | TTM08 | WK15CM | WP35CM | WP40PM | |||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 |

| 1 | – | – | – | 230 | 200 | 190 | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 | |

| 2 | – | – | – | 195 | 170 | 140 | – | – | – | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | – | – | – | 180 | 150 | 125 | – | – | – | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | – | – | – | 160 | 130 | 105 | – | – | – | 190 | 175 | 160 | 205 | 170 | 135 | |

| 5 | – | – | – | – | – | – | – | – | – | 260 | 230 | 210 | 170 | 155 | 135 | |

| 6 | – | – | – | – | – | – | – | – | – | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | – | – | – | – | – | – | – | – | – | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | – | – | – | – | – | – | – | – | – | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | – | – | – | – | – | – | – | – | – | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 120 | 90 | 75 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | – | – | – |

| 2 | 125 | 100 | 70 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | – | – | – | |

| 3 | 130 | 95 | 60 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | – | – | – | |

| N | 1 | 900 | 600 | 500 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | |

| 4 | – | – | – | – | – | – | – | – | – | 66 | 50 | 33 | 65 | 50 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | CPNT | WP40PM | CPNT | WP40PM | CPNT | WP40PM |

| P3–P4 | CPNT | WP35CM | CPNT | WP35CM | CPNT | WP35CM |

| P5–P6 | CPNT | WP35CM | CPNT | WP40PM | CPNT | WP40PM |

| M1–M2 | CPNT | WP40PM | CPNT | WP40PM | CPNT | WP40PM |

| M3 | CPNT | TN7535 | CPNT | WP35CM | CPNT | WP35CM |

| K1–K2 | CPNT | WK15CM | CPNT | WK15CM | CPNT | WK15CM |

| K3 | CPNT | WK15CM | CPNT | WP35CM | CPNT | WP35CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use