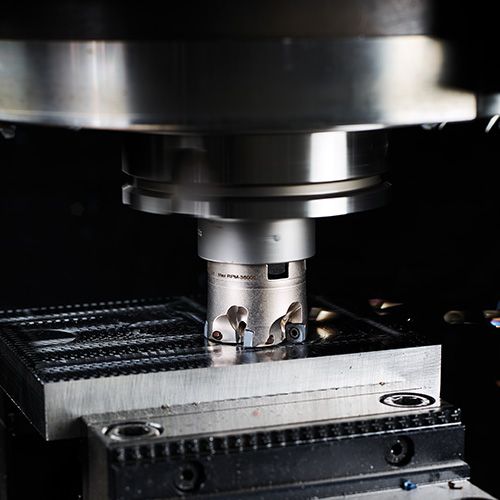

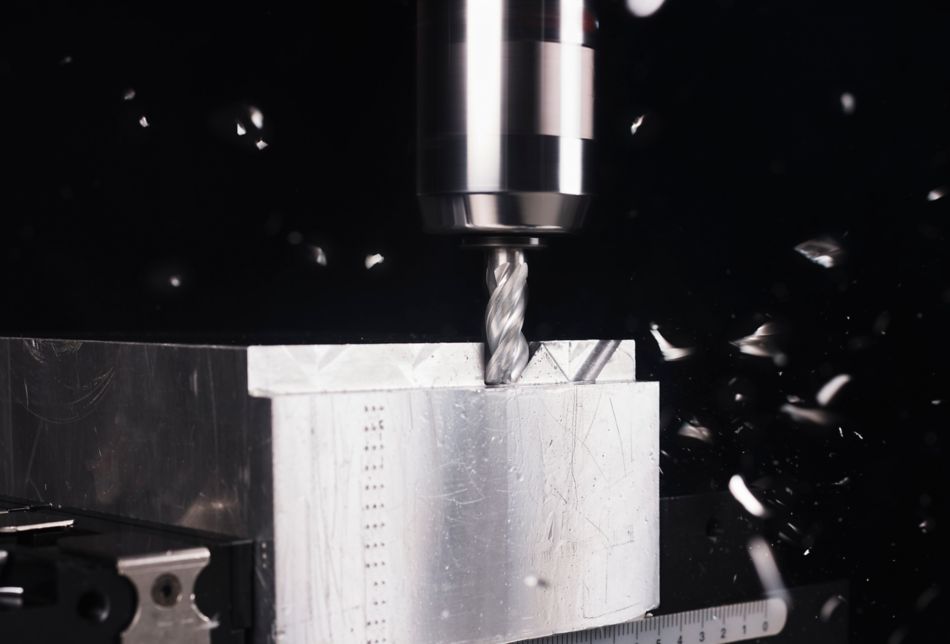

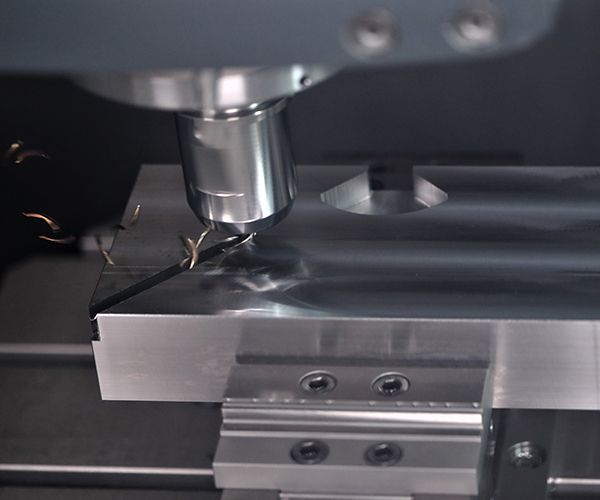

WIDIA Introduces New Chipbreaker for Machining AluminumWIDIA has added an AL Geometry to its ISO Turning portfolio, strengthening its broad offering of tooling solutions. Read more.

WIDIA has added an AL Geometry to its ISO Turning portfolio, strengthening its broad offering of tooling solutions. Read more.