VHSC • Cylindrical End Mills • Inch

Cylindrical End Mills • Inch

物料号6425426

公制样本编号VHSC125Z02C125XD16英制样本编号VHSC125Z02C125XD16

- K 铸铁

- N 非铁材质

端面铣削

螺旋铣削

坡铣: 毛坯

刀柄 — 圆柱 平面

铣削 — 贯通式冷却

刀座

Inclined Square End Mill

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 6425426 |

| 公制样本编号 | VHSC125Z02C125XD16 |

| 英制样本编号 | VHSC125Z02C125XD16 |

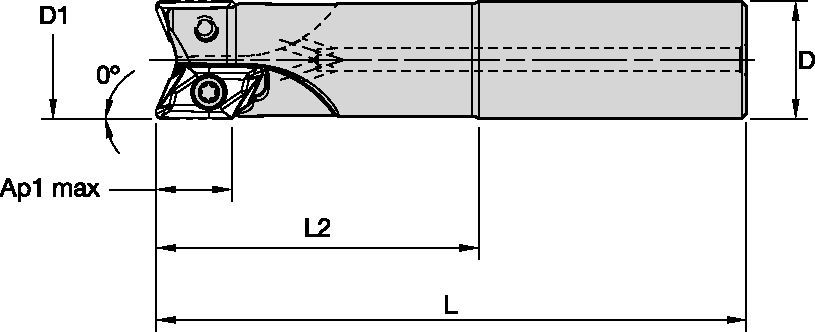

| [D1] 有效的切削直径 | 31.75 mm |

| [D1] 有效的切削直径 | 1.25 in |

| [D]适配接头/刀柄/镗孔直径 | 31.75 mm |

| [D]适配接头/刀柄/镗孔直径 | 1.25 in |

| [L] 总长 | 134.109 mm |

| [L] 总长 | 5.279 in |

| [L2] 刀头长度 | 76.114 mm |

| [L2] 刀头长度 | 2.996 in |

| [AP1MAX] 第一个最大切深 | 16 mm |

| [AP1MAX] 第一个最大切深 | .63 in |

| 刀片数量 | 2 |

| 最大坡铣角度 | 11.5 |

| 最大 RPM | 41500 |

| 冷却液供应 | Y |

| 重量(磅) | 1.49 |

工件材料

- 铸铁

- 非铁材质

Uses and application

端面铣削

螺旋铣削

坡铣: 毛坯

刀柄 — 圆柱 平面

铣削 — 贯通式冷却

刀座

Inclined Square End Mill

Features and benefits

- Productivity booster up to 525in3/min (8600cm3/min MRR at machining Aluminum components.

- Only one cutter body style to load insert with nose radii from .008" (0.2mm) up to .236" (6mm).

- Consistant axial gage length with insert nose radii from .008" (0.2mm) up to .236" (6mm).

- Best in class solution for thin-walled and stepping down machining.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

High Performance Combination Tools

刀片选择指南

| Material Group | Light | General | Heavy | |||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| N1–N2 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

| N3 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

Feeds

建议的初始进给量 [毫米]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | 0,12 | 0,45 | 0,81 | 0,08 | 0,33 | 0,58 | 0,06 | 0,25 | 0,43 | 0,06 | 0,21 | 0,38 | 0,05 | 0,20 | 0,35 | .F..ALP |

| .E..ALP | 0,15 | 0,50 | 0,92 | 0,11 | 0,36 | 0,66 | 0,08 | 0,27 | 0,50 | 0,07 | 0,24 | 0,43 | 0,07 | 0,22 | 0,40 | .E..ALP |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | .005 | .018 | .032 | .003 | .013 | .023 | .003 | .010 | .017 | .002 | .009 | .015 | .002 | .008 | .014 | .F..ALP |

| .E..ALP | .006 | .020 | .037 | .004 | .014 | .027 | .003 | .011 | .020 | .003 | .009 | .017 | .003 | .009 | .016 | .E..ALP |

| Light | General | Heavy |

Speeds

湿式加工的建议初始速度 [米/分钟]

| Material Group | WN10HM | |||

| N | 1 | 2950 | 1800 | 875 |

| 2 | 2950 | 1800 | 875 | |

| 3 | 1600 | 850 | 480 | |

Recommended Starting Speeds for Wet Machining [SFM]

| Material Group | WN10HM | |||

| N | 1 | 9640 | 5880 | 2860 |

| 2 | 9640 | 5880 | 2860 | |

| 3 | 5230 | 2775 | 1565 | |

I have read and accepted the Terms & Conditions of use