VariMill II™ • 5VCC • 5VCE • 5-Flute • Inch

VariMill II™ • 5VCC • 5VCE • Unequal Flute Spacing

物料号6071688

公制样本编号5VCE19EDL20英制样本编号5VCE19EDL20

- P 钢

- S 高温合金

- H 淬火材料

100029626

100029627

Trochoidal Milling

坡铣: 3°

槽铣: 方头立铣

侧铣/方肩铣削: 方头立铣

螺旋角: 38°

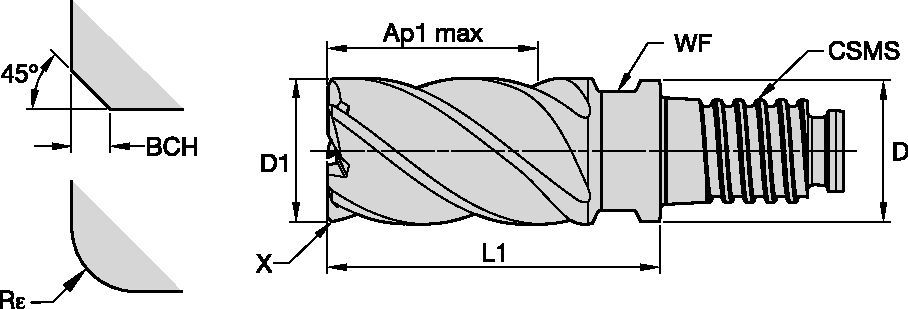

Tool Dimensions: Flute Configuration: 5

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 6071688 |

| 公制样本编号 | 5VCE19EDL20 |

| 英制样本编号 | 5VCE19EDL20 |

| 材质 | WS15PE |

| 机床侧适配接头样式 | DUO-LOCK |

| [D]适配接头/刀柄/镗孔直径 | 25.4 mm |

| [D]适配接头/刀柄/镗孔直径 | 1 in |

| [L1] 量规长度 | 42.9 mm |

| [L1] 量规长度 | 1.689 in |

| [CSMS] 机床侧系统规格 | DL20 |

| [WF] 平面宽度 | 16 mm |

| [WF] 平面宽度 | .6299 in |

| [Re] 刀尖半径 | 3.048 mm |

| [Re] 刀尖半径 | .12 in |

| [Z] 排屑槽数量 | 5 |

| [D1] 有效的切削直径 | 19.05 mm |

| [D1] 有效的切削直径 | .75 in |

| [AP1MAX] 第一个最大切深 | 28.575 mm |

| [AP1MAX] 第一个最大切深 | 1.125 in |

工件材料

- 钢

- 高温合金

- 淬火材料

Uses and application

100029626

100029627

Trochoidal Milling

坡铣: 3°

槽铣: 方头立铣

侧铣/方肩铣削: 方头立铣

螺旋角: 38°

Tool Dimensions: Flute Configuration: 5

Grades

WS15PE

PVD-涂层硬质合金材质,具有优化的化学和工艺,可提高耐磨性。先进的后涂层处理可减少摩擦,有助于在切削超合金时控制热量。

Features and benefits

- Unequal flute spacing minimizes chatter and harmonics for smoother machining.

- Center cutting.

- Ramping up to 3°.

- Five-flute geometry able to slot up to 1 x D.

- Single tool for both roughing and finishing operations requiring fewer setups.

- Standard items listed. Additional styles and coatings made-to-order.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

应用数据

VariMill II™ • 5VCC • Unequal Flute Spacing

|  |  | ||||||||||||||||||

| 侧铣加工(A)和槽铣加工(B) | 短 | 中等 | 长 | 侧铣加工(A)推荐每齿进给率(IPT=英寸/齿)。 槽铣加工(B),每齿进给率降低20%。 | ||||||||||||||||

| A | B | 接杆长度类型 | D1 | |||||||||||||||||

| A | B | WP15PE | WP15PE | WP15PE | ||||||||||||||||

| 切削速度 | 切削速度 | 切削速度 | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||||||

| 材料 分组 | ap | ae | ap | 最小值 | 最大值 | 最小值 | 最大值 | 最小值 | 最大值 | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 0 | 1.5 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 1 | 1.5 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 | |

| 4 | 1.5 x D | 0.5 x D | 0.75 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0033 | .0034 | |

| 5 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 330 | 170 | – | 281 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 6 | 1.5 x D | 0.5 x D | 0.75 x D | 160 | – | 250 | 136 | – | 213 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| M | 1 | 1.5 x D | 0.5 x D | 1 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| K | 1 | 1.5 x D | 0.5 x D | 1 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| S | 1 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 |

| 2 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0021 | .0022 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 120 | – | 156 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 4 | 1.5 x D | 0.5 x D | 1 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0028 | .0030 | |

| H | 1 | 1.5 x D | 0.5 x D | 0.75 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0033 | .0034 |

| 2 | 1.5 x D | 0.2 x D | 0.5 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

VariMill II™ • 5VCE • Unequal Flute Spacing

|  |  | ||||||||||||||||||

| 侧铣加工(A)和槽铣加工(B) | 短 | 中等 | 长 | 侧铣加工(A)推荐每齿进给率(IPT=英寸/齿)。 槽铣加工(B),每齿进给率降低20%。 | ||||||||||||||||

| A | B | 接杆长度类型 | D1 | |||||||||||||||||

| WS15PE | WS15PE | WS15PE | ||||||||||||||||||

| 切削速度 | 切削速度 | 切削速度 | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||||||

| 材料 分组 | ap | ae | ap | 最小值 | 最大值 | 最小值 | 最大值 | 最小值 | 最大值 | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 5 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 330 | 170 | – | 281 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 |

| 6 | 1.5 x D | 0.5 x D | 0.75 x D | 160 | – | 250 | 136 | – | 213 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| S | 1 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0038 | .0041 |

| 2 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0021 | .0022 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 120 | – | 156 | IPT | .0016 | .0020 | .0023 | .0026 | .0031 | .0033 | |

| 4 | 1.5 x D | 0.5 x D | 1 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0028 | .0030 | |

| H | 1 | 1.5 x D | 0.5 x D | 0.75 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0033 | .0034 |

| 2 | 1.5 x D | 0.2 x D | 0.5 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

I have read and accepted the Terms & Conditions of use