Producto similar a:

VariMill III™ ER • Series 7V1E 7V2E • Square End • 7 Flute • Inch

VariMill™

Número de material5971438

Referencia ISO7V2E16006CVReferencia ANSI7V2E16006CV

- P Acero

- M Acero inoxidable

- K Fundición

- S Aleaciones de alta temperatura

- H Materiales endurecidos

Trochoidal Milling

Flute Configuration: 7

Rectificado en rampa: Material en bruto

Fresado lateral/Fresado en escuadra: Placa cuadrada

Estilo de esquina: Radio de esquina

Mango — Liso cilíndrico

Ángulo de la hélice: 38°

SAFE-LOCK Shank

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Comentarios

- Preguntas y Respuestas

| Número de material | 5971438 |

| Referencia ISO | 7V2E16006CV |

| Referencia ANSI | 7V2E16006CV |

| Calidad | WS15PE |

| Tipo de adaptador Lateral de máquina | SAFE-LOCK |

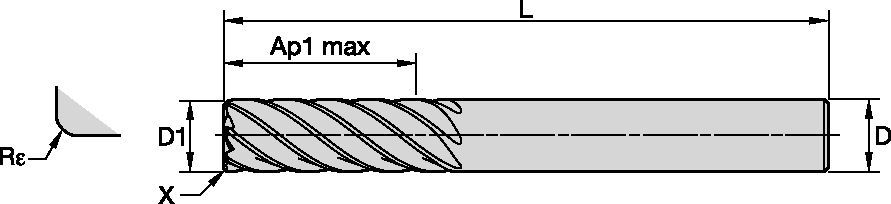

| Radio de esquina [Re] | 1.524 mm |

| Radio de esquina [Re] | .06 in |

| Número de canales [Z] | 7 |

| Diámetro de corte efectivo [D1] | 15.875 mm |

| Diámetro de corte efectivo [D1] | .625 in |

| Adaptador/Mango/Diá int [D] | 15.875 mm |

| Adaptador/Mango/Diá int [D] | .625 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 79.375 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | 3.125 in |

| Longitud total [L] | 139.7 mm |

| Longitud total [L] | 5.5 in |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Aleaciones de alta temperatura

- Materiales endurecidos

Uses and application

Trochoidal Milling

Flute Configuration: 7

Rectificado en rampa: Material en bruto

Fresado lateral/Fresado en escuadra: Placa cuadrada

Estilo de esquina: Radio de esquina

Mango — Liso cilíndrico

Ángulo de la hélice: 38°

SAFE-LOCK Shank

Features and benefits

- Unequal flute spacing.

- Center cutting.

- Ramping angle 3°.

- Optimized for difficult-to-machine workpiece materials.

- Semi-finishing to finishing applications.

- High-speed machining capability.

- Standard items listed. Additional styles and coatings made to order.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Datos de aplicación

Application Data • VariMill III™ ER • Series 7V1E • Semi-Finishing • Inch

| Material |  |  | ||||||||||

| Side Milling (A) | WS15PE | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||

| A | Cutting Speed | D1 | ||||||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 4 | Ap1 max | 0.1 x D | 300 | – | 490 | IPT | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 |

| 5 | Ap1 max | 0.1 x D | 200 | – | 330 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| M | 1 | Ap1 max | 0.1 x D | 300 | – | 380 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Ap1 max | 0.1 x D | 200 | – | 260 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| 3 | Ap1 max | 0.1 x D | 200 | – | 230 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

| S | 1 | Ap1 max | 0.1 x D | 160 | – | 300 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Ap1 max | 0.1 x D | 80 | – | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 3 | Ap1 max | 0.1 x D | 80 | – | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 4 | Ap1 max | 0.1 x D | 160 | – | 200 | IPT | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | |

| H | 1 | Ap1 max | 0.1 x D | 260 | – | 460 | IPT | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 |

| 2 | Ap1 max | 0.1 x D | 230 | – | 390 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

Application Data • VariMill III™ ER • Series 7V1E • Finishing • Inch

| Material |  |  | ||||||||||

| Side Milling (A) | WS15PE | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||

| A | Cutting Speed | D1 | ||||||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 4 | Ap1 max | 0.06 x D | 590 | - | 980 | IPT | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 |

| 5 | Ap1 max | 0.06 x D | 390 | - | 660 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| M | 1 | Ap1 max | 0.06 x D | 590 | - | 750 | IPT | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 |

| 2 | Ap1 max | 0.06 x D | 390 | - | 520 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 3 | Ap1 max | 0.06 x D | 390 | - | 460 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

| S | 1 | Ap1 max | 0.06 x D | 160 | - | 300 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Ap1 max | 0.06 x D | 80 | - | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 3 | Ap1 max | 0.06 x D | 80 | - | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 4 | Ap1 max | 0.06 x D | 160 | - | 200 | IPT | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0030 | |

| H | 1 | Ap1 max | 0.06 x D | 520 | - | 920 | IPT | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 |

| 2 | Ap1 max | 0.06 x D | 460 | - | 790 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

Application Data • VariMill III™ ER • Series 7V2E • Finishing • Inch

| Material |  |  | ||||||||||

| Side Milling (A) | WS15PE | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||

| A | Cutting Speed | D1 | ||||||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | Ap1 max | 0.05 x D | 980 | – | 1310 | IPT | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 |

| 1 | Ap1 max | 0.05 x D | 980 | – | 1310 | IPT | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | |

| 2 | Ap1 max | 0.05 x D | 920 | – | 1250 | IPT | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | |

| 3 | Ap1 max | 0.05 x D | 790 | – | 1050 | IPT | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | |

| 4 | Ap1 max | 0.05 x D | 590 | – | 980 | IPT | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 | |

| 5 | Ap1 max | 0.05 x D | 390 | – | 660 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 6 | Ap1 max | 0.05 x D | 330 | – | 490 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

| M | 1 | Ap1 max | 0.05 x D | 590 | – | 750 | IPT | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 |

| 2 | Ap1 max | 0.05 x D | 390 | – | 520 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 3 | Ap1 max | 0.05 x D | 390 | – | 460 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

| K | 1 | Ap1 max | 0.05 x D | 790 | – | 980 | IPT | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 |

| 2 | Ap1 max | 0.05 x D | 720 | – | 920 | IPT | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | |

| 3 | Ap1 max | 0.05 x D | 720 | – | 850 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| S | 1 | Ap1 max | 0.05 x D | 160 | – | 300 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Ap1 max | 0.05 x D | 80 | – | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 3 | Ap1 max | 0.05 x D | 80 | – | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 4 | Ap1 max | 0.05 x D | 160 | – | 200 | IPT | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | |

| H | 1 | Ap1 max | 0.05 x D | 520 | – | 920 | IPT | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 |

| 2 | Ap1 max | 0.06 x D | 460 | – | 790 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use