Producto similar a:

M100 • RDMT-M0T • RD0802..

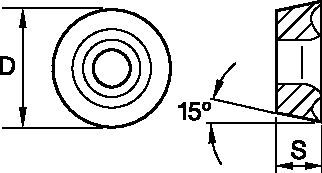

iC08 • Plaquitas

Número de material6901186

Referencia ISORDMT0802M0TReferencia ANSIRDMT0802M0T

- P Acero

- M Acero inoxidable

- K Fundición

- S Aleaciones de alta temperatura

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Comentarios

- Preguntas y Respuestas

| Número de material | 6901186 |

| Referencia ISO | RDMT0802M0T |

| Referencia ANSI | RDMT0802M0T |

| Calidad | WP35CM |

| Filos de corte por plaquita | 1 |

| Tamaño IC de plaquita [D] | 8 mm |

| Tamaño IC de plaquita [D] | 0.315 in |

| Grosor de plaquita [S] | 2.38 mm |

| Grosor de plaquita [S] | 0.0938 in |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Aleaciones de alta temperatura

Features and benefits

- Geometría positiva prensada con precisión para menores fuerzas de corte.

- La primera opción para el mecanizado general, acero inoxidable y aleaciones a altas temperaturas en operaciones de desbaste.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Feeds

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| RDMW- | 0,19 | 0,29 | 0,42 | 0,14 | 0,21 | 0,30 | 0,10 | 0,16 | 0,23 | 0,09 | 0,14 | 0,20 | 0,08 | 0,13 | 0,18 | RDMW- |

| RDHT-T | 0,23 | 0,31 | 0,63 | 0,17 | 0,23 | 0,45 | 0,13 | 0,17 | 0,34 | 0,11 | 0,15 | 0,29 | 0,10 | 0,14 | 0,27 | RDHT-T |

| RDMT-T | 0,23 | 0,31 | 0,63 | 0,17 | 0,23 | 0,45 | 0,13 | 0,17 | 0,34 | 0,11 | 0,15 | 0,29 | 0,10 | 0,14 | 0,27 | RDMT-T |

| RDMW-T | 0,23 | 0,42 | 0,73 | 0,17 | 0,30 | 0,53 | 0,13 | 0,23 | 0,39 | 0,11 | 0,20 | 0,34 | 0,10 | 0,18 | 0,32 | RDMW-T |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| RDMW- | 0,22 | 0,34 | 0,48 | 0,16 | 0,24 | 0,35 | 0,12 | 0,18 | 0,26 | 0,10 | 0,16 | 0,23 | 0,09 | 0,15 | 0,21 | RDMW- |

| RDHT-T | 0,27 | 0,36 | 0,72 | 0,19 | 0,26 | 0,52 | 0,14 | 0,20 | 0,39 | 0,13 | 0,17 | 0,34 | 0,12 | 0,16 | 0,31 | RDHT-T |

| RDMT-T | 0,27 | 0,36 | 0,72 | 0,19 | 0,26 | 0,52 | 0,14 | 0,20 | 0,39 | 0,13 | 0,17 | 0,34 | 0,12 | 0,16 | 0,31 | RDMT-T |

| RDMW-T | 0,27 | 0,48 | 0,85 | 0,19 | 0,35 | 0,61 | 0,14 | 0,26 | 0,46 | 0,13 | 0,23 | 0,40 | 0,12 | 0,21 | 0,36 | RDMW-T |

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| RDMW- | 0,39 | 0,60 | 0,87 | 0,28 | 0,44 | 0,62 | 0,21 | 0,33 | 0,47 | 0,18 | 0,28 | 0,41 | 0,17 | 0,26 | 0,37 | RDMW- |

| RDHT-T | 0,48 | 0,65 | 1,31 | 0,35 | 0,47 | 0,94 | 0,26 | 0,35 | 0,70 | 0,23 | 0,30 | 0,61 | 0,21 | 0,28 | 0,56 | RDHT-T |

| RDMT-T | 0,48 | 0,65 | 1,31 | 0,35 | 0,47 | 0,94 | 0,26 | 0,35 | 0,70 | 0,23 | 0,30 | 0,61 | 0,21 | 0,28 | 0,56 | RDMT-T |

| RDMW-T | 0,48 | 0,87 | 1,54 | 0,35 | 0,62 | 1,10 | 0,26 | 0,47 | 0,82 | 0,23 | 0,41 | 0,71 | 0,21 | 0,37 | 0,65 | RDMW-T |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| RDMW- | 0,28 | 0,44 | 0,63 | 0,20 | 0,32 | 0,46 | 0,15 | 0,24 | 0,34 | 0,13 | 0,21 | 0,30 | 0,12 | 0,19 | 0,27 | RDMW- |

| RDHT-T | 0,35 | 0,47 | 0,95 | 0,25 | 0,34 | 0,69 | 0,19 | 0,26 | 0,51 | 0,17 | 0,22 | 0,45 | 0,15 | 0,20 | 0,41 | RDHT-T |

| RDMT-T | 0,35 | 0,47 | 0,95 | 0,25 | 0,34 | 0,69 | 0,19 | 0,26 | 0,51 | 0,17 | 0,22 | 0,45 | 0,15 | 0,20 | 0,41 | RDMT-T |

| RDMW-T | 0,35 | 0,63 | 1,12 | 0,25 | 0,46 | 0,80 | 0,19 | 0,34 | 0,60 | 0,17 | 0,30 | 0,52 | 0,15 | 0,27 | 0,48 | RDMW-T |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| RDMW- | .007 | .011 | .016 | .005 | .008 | .012 | .004 | .006 | .009 | .003 | .005 | .008 | .003 | .005 | .007 | RDMW- |

| RDHT-T | .009 | .012 | .024 | .007 | .009 | .018 | .005 | .007 | .013 | .004 | .006 | .011 | .004 | .005 | .011 | RDHT-T |

| RDMT-T | .009 | .012 | .024 | .007 | .009 | .018 | .005 | .007 | .013 | .004 | .006 | .011 | .004 | .005 | .011 | RDMT-T |

| RDMW-T | .009 | .016 | .028 | .007 | .012 | .021 | .005 | .009 | .015 | .004 | .008 | .013 | .004 | .007 | .012 | RDMW-T |

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| RDMW- | .008 | .013 | .019 | .006 | .009 | .014 | .005 | .007 | .010 | .004 | .006 | .009 | .004 | .006 | .008 | RDMW- |

| RDHT-T | .010 | .014 | .028 | .008 | .010 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .006 | .012 | RDHT-T |

| RDMT-T | .010 | .014 | .028 | .008 | .010 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .006 | .012 | RDMT-T |

| RDMW-T | .010 | .019 | .033 | .008 | .014 | .024 | .006 | .010 | .018 | .005 | .009 | .015 | .005 | .008 | .014 | RDMW-T |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| RDMW- | .015 | .023 | .034 | .011 | .017 | .024 | .008 | .013 | .018 | .007 | .011 | .016 | .007 | .010 | .014 | RDMW- |

| RDHT-T | .019 | .025 | .051 | .014 | .018 | .037 | .010 | .014 | .027 | .009 | .012 | .024 | .008 | .011 | .022 | RDHT-T |

| RDMT-T | .019 | .025 | .051 | .014 | .018 | .037 | .010 | .014 | .027 | .009 | .012 | .024 | .008 | .011 | .022 | RDMT-T |

| RDMW-T | .019 | .034 | .060 | .014 | .024 | .043 | .010 | .018 | .032 | .009 | .016 | .028 | .008 | .014 | .025 | RDMW-T |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| RDMW- | .011 | .017 | .025 | .008 | .012 | .018 | .006 | .009 | .013 | .005 | .008 | .012 | .005 | .007 | .011 | RDMW- |

| RDHT-T | .014 | .018 | .037 | .010 | .013 | .027 | .007 | .010 | .020 | .006 | .009 | .017 | .006 | .008 | .016 | RDHT-T |

| RDMT-T | .014 | .018 | .037 | .010 | .013 | .027 | .007 | .010 | .020 | .006 | .009 | .017 | .006 | .008 | .016 | RDMT-T |

| RDMW-T | .014 | .025 | .043 | .010 | .018 | .031 | .007 | .013 | .023 | .006 | .012 | .020 | .006 | .011 | .019 | RDMW-T |

Speeds

Velocidades iniciales recomendadas [m/min]

| Grupo de materiales | THM | TN6525 | TN6540 | TTM08 | WK15CM | WP35CM | WS30PM | WS40PM | |||||||||||||||||

| P | 1 | – | – | – | 410 | 320 | 280 | 360 | 280 | 240 | 230 | 200 | 190 | – | – | – | 455 | 395 | 370 | – | – | – | – | – | – |

| 2 | – | – | – | 320 | 250 | 215 | 250 | 190 | 170 | 195 | 170 | 140 | – | – | – | 280 | 255 | 230 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 215 | 185 | 215 | 170 | 140 | 180 | 150 | 125 | – | – | – | 255 | 230 | 205 | – | – | – | – | – | – | |

| 4 | – | – | – | 235 | 170 | 145 | 180 | 130 | 110 | 160 | 130 | 105 | – | – | – | 190 | 175 | 160 | – | – | – | – | – | – | |

| 5 | – | – | – | 310 | 235 | 200 | 240 | 180 | 150 | – | – | – | – | – | – | 260 | 230 | 210 | – | – | – | 205 | 175 | 145 | |

| 6 | – | – | – | 205 | 160 | 130 | 160 | 120 | 100 | – | – | – | – | – | – | 160 | 135 | 110 | – | – | – | 180 | 130 | 95 | |

| M | 1 | – | – | – | 190 | 120 | 80 | 130 | 80 | 60 | – | – | – | – | – | – | 205 | 185 | 155 | 270 | 240 | 220 | 250 | 205 | 170 |

| 2 | – | – | – | 120 | 80 | 50 | 80 | 50 | 40 | – | – | – | – | – | – | 185 | 160 | 140 | 245 | 215 | 175 | 215 | 175 | 145 | |

| 3 | – | – | – | 125 | 80 | 55 | 85 | 50 | 40 | – | – | – | – | – | – | 145 | 130 | 115 | 185 | 160 | 125 | 175 | 130 | 100 | |

| K | 1 | 120 | 90 | 75 | 275 | 245 | 220 | 220 | 205 | 180 | – | – | – | 505 | 460 | 410 | 295 | 265 | 240 | – | – | – | – | – | – |

| 2 | 125 | 100 | 70 | 215 | 190 | 180 | 175 | 155 | 140 | – | – | – | 400 | 355 | 330 | 235 | 210 | 190 | – | – | – | – | – | – | |

| 3 | 130 | 95 | 60 | 180 | 160 | 145 | 155 | 145 | 125 | – | – | – | 335 | 300 | 275 | 195 | 175 | 160 | – | – | – | – | – | – | |

| N | 1 | 900 | 600 | 500 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 35 | 30 | – | – | – | – | – | – | – | – | – | 55 | 50 | 35 | 50 | 40 | 30 |

| 2 | – | – | – | – | – | – | 25 | 20 | 10 | – | – | – | – | – | – | – | – | – | 55 | 50 | 35 | 50 | 40 | 30 | |

| 3 | – | – | – | – | – | – | 70 | 40 | 30 | – | – | – | – | – | – | – | – | – | 65 | 55 | 35 | 60 | 50 | 30 | |

| 4 | – | – | – | – | – | – | 60 | 30 | 25 | – | – | – | – | – | – | 66 | 50 | 33 | 100 | 70 | 50 | 70 | 60 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Grupo de materiales | THM | TN6525 | TN6540 | WP35CM | |||||||||

| P | 1 | – | – | – | 1340 | 1045 | 925 | 1180 | 925 | 785 | 1790 | 1555 | 1460 |

| 2 | – | – | – | 1045 | 830 | 710 | 830 | 630 | 550 | 1105 | 1000 | 905 | |

| 3 | – | – | – | 925 | 710 | 610 | 710 | 550 | 450 | 1000 | 905 | 805 | |

| 4 | – | – | – | 770 | 550 | 475 | 590 | 430 | 355 | 750 | 690 | 630 | |

| 5 | – | – | – | 1025 | 770 | 650 | 785 | 590 | 490 | 1025 | 905 | 830 | |

| 6 | – | – | – | 670 | 535 | 430 | 535 | 395 | 335 | 630 | 535 | 430 | |

| M | 1 | – | – | – | 630 | 395 | 260 | 430 | 260 | 200 | 805 | 725 | 610 |

| 2 | – | – | – | 395 | 260 | 155 | 260 | 155 | 140 | 725 | 630 | 550 | |

| 3 | – | – | – | 415 | 260 | 180 | 275 | 155 | 140 | 570 | 510 | 450 | |

| K | 1 | 390 | 295 | 245 | 905 | 805 | 725 | 725 | 670 | 590 | 1165 | 1045 | 940 |

| 2 | 410 | 325 | 225 | 710 | 630 | 590 | 570 | 510 | 450 | 925 | 830 | 750 | |

| 3 | 425 | 310 | 195 | 590 | 535 | 475 | 510 | 475 | 415 | 770 | 690 | 630 | |

| N | 1 | 2950 | 1965 | 1640 | – | – | – | – | – | – | – | – | – |

| 2 | 2245 | 1525 | 1260 | – | – | – | – | – | – | – | – | – | |

| 3 | 1475 | 915 | 655 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 155 | 120 | 95 | – | – | – |

| 2 | – | – | – | – | – | – | 80 | 60 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | 235 | 140 | 95 | – | – | – | |

| 4 | – | – | – | – | – | – | 200 | 95 | 80 | 260 | 200 | 130 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| Grupo de materiales | TTM08 | WK15CM | WS30PM | WS40PM | |||||||||

| P | 1 | 750 | 655 | 620 | – | – | – | – | – | – | – | – | – |

| 2 | 635 | 555 | 455 | – | – | – | – | – | – | – | – | – | |

| 3 | 590 | 490 | 410 | – | – | – | – | – | – | – | – | – | |

| 4 | 520 | 425 | 340 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | 560 | 475 | 395 | |

| 6 | – | – | – | – | – | – | – | – | – | 490 | 360 | 260 | |

| M | 1 | – | – | – | – | – | – | 890 | 785 | 725 | 690 | 560 | 460 |

| 2 | – | – | – | – | – | – | 805 | 710 | 570 | 590 | 475 | 395 | |

| 3 | – | – | – | – | – | – | 610 | 535 | 415 | 475 | 360 | 280 | |

| K | 1 | – | – | – | 1655 | 1520 | 1340 | – | – | – | – | – | – |

| 2 | – | – | – | 1320 | 1165 | 1080 | – | – | – | – | – | – | |

| 3 | – | – | – | 1105 | 985 | 905 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 |

| 2 | – | – | – | – | – | – | 180 | 155 | 120 | 130 | 115 | 80 | |

| 3 | – | – | – | – | – | – | 215 | 180 | 120 | 165 | 130 | 80 | |

| 4 | – | – | – | – | – | – | 335 | 235 | 155 | 195 | 165 | 100 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

Insert Selection

Insert Selection Guide

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | ||||

| Grupo de materiales | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | RDMT-T | WP35CM | RDMT-T | WP35CM | RDMT-T | WP35CM |

| P3–P4 | RDMT-T | WP35CM | RDMW-T | TN6540 | RDMW-T | TN6540 |

| P5–P6 | RDMT-T | WP35CM | RDMT-T | WP35CM | RDMT-T | WP35CM |

| M1–M2 | RDHT-T | WP35CM | RDHT-T | WP35CM | RDMT-T | WP35CM |

| M3 | RDHT-T | WP35CM | RDHT-T | WP35CM | RDMT-T | WP35CM |

| K1–K2 | – | – | RDMT-T | WP35CM | RDMT-T | WP35CM |

| K3 | – | – | RDMT-T | WP35CM | RDMT-T | WP35CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use