Producto similar a:

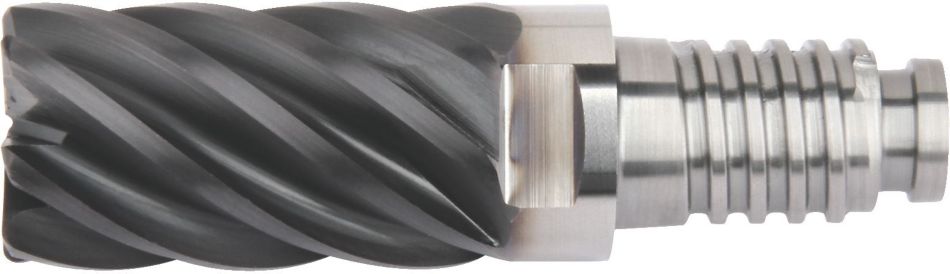

VariMill™ • 7VCE • 7-Flute with Eccentric Relief Grind • Inch

VariMill III™ • 7VCE • Unequal Flute Spacing • Eccentric Relief

Número de material100075163

Features and benefits

- Unequal flute spacing minimizes chatter and harmonics for smoother machining.

- Center cutting.

- Optimized geometry for titanium machining.

- Single tool for both roughing and finishing operations requiring fewer setups.

- Standard items listed. Additional styles and coatings made-to-order.

Trochoidal Milling

Flute Configuration: 7

Rectificado en rampa: Material en bruto

Estilo de esquina: Radio de esquina

Fresado lateral/Fresado en escuadra: Placa cuadrada

Ángulo de la hélice: 38°

VariMill III™ • 7VCE • Unequal Flute Spacing • Roughing

|  | ||||||||||||||||||

| Fresado lateral (A) | corto | medio | largo | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | alcance adaptador | D1 | |||||||||||||||||

| WS15PE | WS15PE | WS15PE | |||||||||||||||||

| Velocidad de corte | Velocidad de corte | Velocidad de corte | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | ||||||||||

| Grupo de materiales | ap | ae | Mín | Máx. | Mín | Máx. | Mín | Máx. | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 4 | Ap max | 0.3 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0016 | .0021 | .0024 | .0027 | .0031 | .0032 |

| 5 | Ap max | 0.3 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0015 | .0018 | .0022 | .0025 | .0029 | .0031 | |

| M | 1 | Ap max | 0.3 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 |

| 2 | Ap max | 0.3 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0015 | .0018 | .0022 | .0025 | .0029 | .0031 | |

| 3 | Ap max | 0.3 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0012 | .0015 | .0018 | .0020 | .0022 | .0023 | |

| S | 1 | Ap max | 0.3 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0018 | .0023 | .0027 | .0031 | .0036 | .0039 |

| 2 | Ap max | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0012 | .0015 | .0016 | .0019 | .0021 | |

| 3 | Ap max | 0.3 x D | 200 | – | 260 | 160 | – | 208 | 120 | – | 156 | IPT | .0015 | .0018 | .0022 | .0025 | .0029 | .0031 | |

| 4 | Ap max | 0.3 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0013 | .0017 | .0020 | .0023 | .0026 | .0028 | |

| H | 1 | Ap max | 0.3 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0016 | .0021 | .0024 | .0027 | .0031 | .0032 |

| 2 | Ap max | 0.3 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0012 | .0015 | .0018 | .0020 | .0022 | .0023 | |

VariMill III™ • 7VCE • Unequal Flute Spacing • Finishing

|  | ||||||||||||||||||

| Fresado lateral (A) | corto | medio | largo | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | alcance adaptador | D1 | |||||||||||||||||

| A | WS15PE | WS15PE | WS15PE | ||||||||||||||||

| Velocidad de corte | Velocidad de corte | Velocidad de corte | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | ||||||||||

| Grupo de materiales | ap | ae | Mín | Máx. | Mín | Máx. | Mín | Máx. | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||||

| P | 4 | Ap max | 0.06 x D | 590 | – | 980 | 531 | – | 882 | 531 | – | 882 | IPT | .0020 | .0025 | .0029 | .0032 | .0037 | .0039 |

| 5 | Ap max | 0.06 x D | 390 | – | 660 | 331.5 | – | 561 | 312 | – | 528 | IPT | .0018 | .0022 | .0026 | .0030 | .0035 | .0037 | |

| M | 1 | Ap max | 0.06 x D | 590 | – | 750 | 472 | – | 600 | 413 | – | 525 | IPT | .0022 | .0028 | .0033 | .0037 | .0043 | .0047 |

| 2 | Ap max | 0.06 x D | 390 | – | 520 | 312 | – | 416 | 273 | – | 364 | IPT | .0018 | .0022 | .0026 | .0030 | .0035 | .0037 | |

| 3 | Ap max | 0.06 x D | 390 | – | 460 | 312 | – | 368 | 273 | – | 322 | IPT | .0015 | .0018 | .0021 | .0024 | .0027 | .0028 | |

| S | 1 | Ap max | 0.06 x D | 330 | – | 590 | 264 | – | 472 | 198 | – | 354 | IPT | .0022 | .0028 | .0033 | .0037 | .0043 | .0047 |

| 2 | Ap max | 0.06 x D | 160 | – | 260 | 128 | – | 208 | 96 | – | 156 | IPT | .0012 | .0015 | .0017 | .0020 | .0023 | .0025 | |

| 3 | Ap max | 0.06 x D | 390 | – | 520 | 312 | – | 416 | 234 | – | 312 | IPT | .0018 | .0022 | .0026 | .0030 | .0035 | .0037 | |

| 4 | Ap max | 0.06 x D | 330 | – | 390 | 264 | – | 312 | 198 | – | 234 | IPT | .0016 | .0020 | .0024 | .0027 | .0032 | .0034 | |

| H | 1 | Ap max | 0.06 x D | 520 | – | 920 | 416 | – | 736 | 312 | – | 552 | IPT | .0020 | .0025 | .0029 | .0032 | .0037 | .0039 |

| 2 | Ap max | 0.06 x D | 460 | – | 790 | 368 | – | 632 | 276 | – | 474 | IPT | .0015 | .0018 | .0021 | .0024 | .0027 | .0028 | |