Product Similar To:

VHSC • Cylindrical End Mills • Metric

Cylindrical End Mills • Metric

Material Number6425260

ISO Catalog IDVHSC032Z03A32XD16ANSI Catalog IDVHSC032Z03A32XD16

- K Cast Iron

- N Non-Ferrous

- .caption

Face Milling

Helical Milling

Ramping: Blank

Shank - Cylindrical Plain

Milling - Through Coolant

Pocketing

Inclined Square End Mill

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 6425260 |

| ISO Catalog ID | VHSC032Z03A32XD16 |

| ANSI Catalog ID | VHSC032Z03A32XD16 |

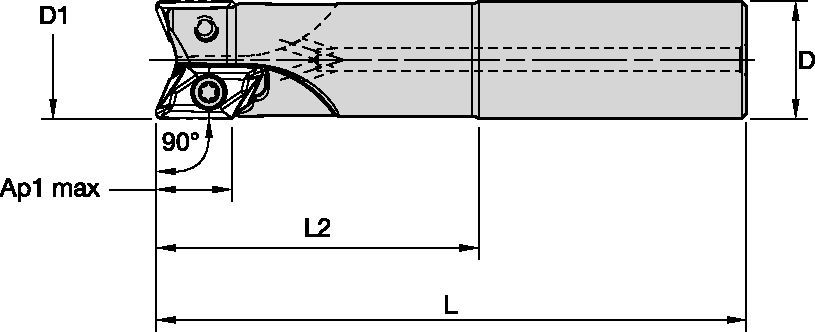

| [D1] Effective Cutting Diameter | 32 mm |

| [D1] Effective Cutting Diameter | 1.26 in |

| [D] Adapter / Shank / Bore Diameter | 32 mm |

| [D] Adapter / Shank / Bore Diameter | 1.26 in |

| [L] Overall Length | 135 mm |

| [L] Overall Length | 5.315 in |

| [L1] Gage Length | 135 mm |

| [L1] Gage Length | 5.315 in |

| [L2] Head Length | 75 mm |

| [L2] Head Length | 2.953 in |

| [AP1MAX] 1st Maximum Cutting Depth | 16 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.63 in |

| Number of Inserts | 3 |

| Maximum Ramping Angle | 11.4 |

| Max RPM | 41500 |

| Coolant Supply | Y |

| Weight Kilograms | 0.65 |

Workpiece Materials

- Cast Iron

- Non-Ferrous

- .caption

Uses and application

Face Milling

Helical Milling

Ramping: Blank

Shank - Cylindrical Plain

Milling - Through Coolant

Pocketing

Inclined Square End Mill

Features and benefits

- Productivity booster up to 525in3/min (8600cm3/min MRR at machining Aluminum components.

- Only one cutter body style to load insert with nose radii from .008" (0.2mm) up to .236" (6mm).

- Consistant axial gage length with insert nose radii from .008" (0.2mm) up to .236" (6mm).

- Best in class solution for thin-walled and stepping down machining.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | 0,12 | 0,45 | 0,81 | 0,08 | 0,33 | 0,58 | 0,06 | 0,25 | 0,43 | 0,06 | 0,21 | 0,38 | 0,05 | 0,20 | 0,35 | .F..ALP |

| .E..ALP | 0,15 | 0,50 | 0,92 | 0,11 | 0,36 | 0,66 | 0,08 | 0,27 | 0,50 | 0,07 | 0,24 | 0,43 | 0,07 | 0,22 | 0,40 | .E..ALP |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | .005 | .018 | .032 | .003 | .013 | .023 | .003 | .010 | .017 | .002 | .009 | .015 | .002 | .008 | .014 | .F..ALP |

| .E..ALP | .006 | .020 | .037 | .004 | .014 | .027 | .003 | .011 | .020 | .003 | .009 | .017 | .003 | .009 | .016 | .E..ALP |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds For Wet Machining [m/min]

| Material Group | WN10HM | |||

| N | 1 | 2950 | 1800 | 875 |

| 2 | 2950 | 1800 | 875 | |

| 3 | 1600 | 850 | 480 | |

Recommended Starting Speeds for Wet Machining [SFM]

| Material Group | WN10HM | |||

| N | 1 | 9640 | 5880 | 2860 |

| 2 | 9640 | 5880 | 2860 | |

| 3 | 5230 | 2775 | 1565 | |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| N1–N2 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

| N3 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

I have read and accepted the Terms & Conditions of use