Product Similar To:

X-Feed™ • Series 70N6 71N6 • 37–52 HRC • High Feed • 6 Flute • Cylindrical Shank • Metric

Series 70N6 71N6 • 37–52 HRC • Vision Plus™ X-Feed™

Material Number3484748

ISO Catalog ID70N616006MTANSI Catalog ID70N616006MT

- P Steel

- H Hardened Materials

Ramping: Blank

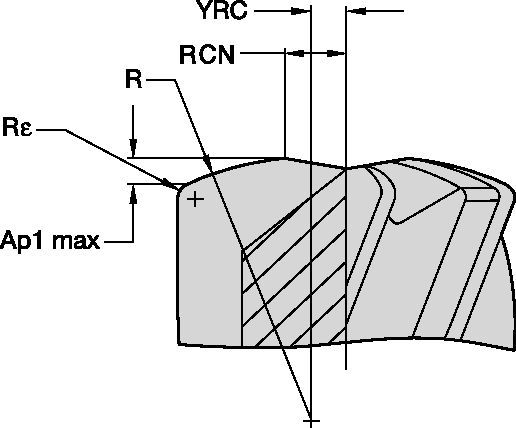

Corner Style: Torus

Helix Angle: 20°

Tool Dimensions: Flute Configuration: 6

3D Profiling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3484748 |

| ISO Catalog ID | 70N616006MT |

| ANSI Catalog ID | 70N616006MT |

| Grade | ALTIN-MT1 |

| Adapter Style Machine Side | Straight-Cylindrical |

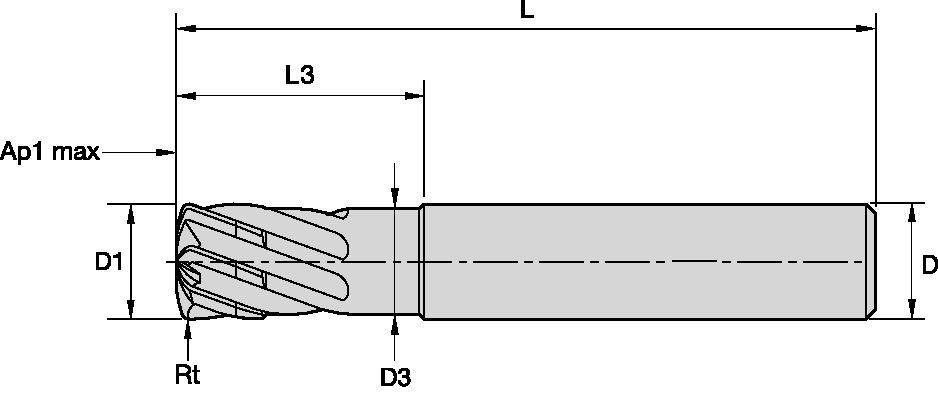

| [D1] Effective Cutting Diameter | 16 mm |

| [D1] Effective Cutting Diameter | .63 in |

| [D] Adapter / Shank / Bore Diameter | 16 mm |

| [D] Adapter / Shank / Bore Diameter | .6299 in |

| [D3] Neck Diameter | 15 mm |

| [D3] Neck Diameter | .591 in |

| [AP1MAX] 1st Maximum Cutting Depth | 0.84 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .0331 in |

| [L3] Usable Length | 48 mm |

| [L3] Usable Length | 1.89 in |

| [L] Overall Length | 110 mm |

| [L] Overall Length | 4.33 in |

| [Re] Corner Radius | 1 mm |

| [Re] Corner Radius | .0394 in |

| Theoretical Cor Rad Prog I [RT] | 1.66 mm |

| Theoretical Cor Rad Prog I [RT] | .0654 in |

| [Z] Number of Flutes | 6 |

Workpiece Materials

- Steel

- Hardened Materials

Uses and application

Ramping: Blank

Corner Style: Torus

Helix Angle: 20°

Tool Dimensions: Flute Configuration: 6

3D Profiling

Features and benefits

- Non-center cutting.

- Standard items listed. Additional styles and coatings made to order.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

Series 70N6 71N6 • Vision Plus X-Feed

|  | ||||||||||||

| Profile Milling | AlTiN | Recommended feed per tooth (fz = mm/th) for 3D milling/profiling (A) | |||||||||||

| A | Cutting Speed | D1 | |||||||||||

| Material | ap | ae | Min | Max | mm | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 4 | 0,05 x D | 0,55 x D | 160 | – | 180 | fz | 0,300 | 0,500 | 0,500 | 0,500 | 0,600 | 0,700 |

| H | 1 | 0,05 x D | 0,55 x D | 140 | – | 160 | fz | 0,300 | 0,500 | 0,500 | 0,500 | 0,600 | 0,700 |

| 2 | 0,05 x D | 0,55 x D | 100 | – | 120 | fz | 0,200 | 0,300 | 0,300 | 0,400 | 0,500 | 0,600 | |

| 70N6 公制 | ||||||||||||||||

| Geometrical Parameters | 圆周插补和线性插补的坡铣指南 | |||||||||||||||

| Circular Interpolation | 线性插补 | |||||||||||||||

| 孔直径的允许范围 | 根据坡铣角度计算的长度 (mm) | |||||||||||||||

| 直径 | diameter | ap max | Rfm | Rt | Rc | Xfm | Yfm | YD | 编号 | 坡铣角度(°) | ||||||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | 刃数 | Smallest | Largest | 1 | 2 | 3 | 4 | 5 | |

| 70N606003MT | 6 | 0,32 | 6 | 0,62 | 0,375 | 0,32 | 0,75 | 1,32 | 6 | 8,64 | 12 | 18,12 | 9,06 | 6,03 | 4,52 | 3,61 |

| 70N608003MT | 8 | 0,42 | 8 | 0,83 | 0,500 | 0,42 | 1,00 | 1,76 | 6 | 11,52 | 16 | 24,16 | 12,08 | 8,05 | 6,03 | 4,82 |

| 70N610004MT | 10 | 0,53 | 10 | 1,04 | 0,625 | 0,53 | 1,25 | 2,20 | 6 | 14,4 | 20 | 30,20 | 15,09 | 10,06 | 7,54 | 6,02 |

| 70N612005MT | 12 | 0,63 | 12 | 1,24 | 0,750 | 0,63 | 1,50 | 2,64 | 6 | 17,28 | 24 | 36,24 | 18,11 | 12,07 | 9,05 | 7,23 |

| 70N616006MT | 16 | 0,84 | 16 | 1,66 | 1,000 | 0,84 | 2,00 | 3,52 | 6 | 23,04 | 32 | 48,31 | 24,15 | 16,09 | 12,06 | 9,64 |

| 70N620007MT | 20 | 1,05 | 20 | 2,07 | 1,250 | 1,05 | 2,50 | 4,40 | 6 | 28,8 | 40 | 60,39 | 30,19 | 20,11 | 15,08 | 12,05 |

| 推荐进给率 | 100% | 70% | 50% | 30% | 10% | |||||||||||

I have read and accepted the Terms & Conditions of use