Product Similar To:

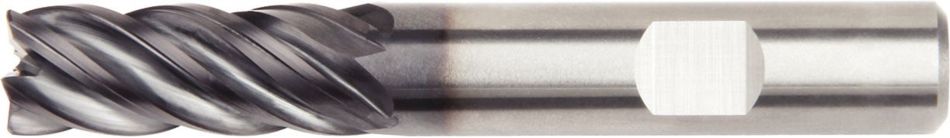

VariMill II ER • Series 577E • Square End • Eccentric Relief • 5 Flute • Metric

VariMill II™ ER • Series 577E • Metric

Material Number100006710

Features and benefits

- Unequal flute spacing

- Center cutting

- Optimized geometry for titanium machining

- Single tool for both roughing and finishing operations requiring fewer setups

- Standard items listed and additional styles and coatings made-to-order

Trochoidal Milling

Ramping: Blank

Slotting: Square End

Corner Style: Corner Radius

Corner Style: Square End

Shank - Cylindrical Plain

Shank - Cylindrical Weldon

Side Milling/Shoulder Milling: Square End

Helix Angle: 38°

Tool Dimensions: Flute Configuration: 5

SAFE-LOCK Shank

Series 577E • VariMill II ER • Victory Grades

| Material |  |  |  | ||||||||||||

| Side Milling (A) and Slotting (B) | WS15PE | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||||||||

| A | B | Cutting Speed | D1 | ||||||||||||

| ap | ae | ap | Min | Max | mm | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | |||

| P | 4 | 1,5 x D | 0,5 x D | 0,75 x D | 90 | – | 150 | fz | 0,054 | 0,062 | 0,070 | 0,077 | 0,083 | 0,088 | 0,098 |

| 5 | 1,5 x D | 0,5 x D | 1 x D | 60 | – | 100 | fz | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 | 0,091 | |

| 6 | 1,5 x D | 0,5 x D | 0,75 x D | 50 | – | 75 | fz | 0,040 | 0,047 | 0,052 | 0,057 | 0,061 | 0,065 | 0,071 | |

| M | 1 | 1,5 x D | 0,5 x D | 1 x D | 90 | – | 115 | fz | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | 0,114 |

| 2 | 1,5 x D | 0,5 x D | 1 x D | 60 | – | 80 | fz | 0,048 | 0,056 | 0,063 | 0,070 | 0,076 | 0,081 | 0,091 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 60 | – | 70 | fz | 0,040 | 0,047 | 0,052 | 0,057 | 0,061 | 0,065 | 0,071 | |

| S | 1 | 1,5 x D | 0,3 x D | 0,3 x D | 50 | – | 90 | fz | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | 0,114 |

| 2 | 1,5 x D | 0,3 x D | 0,3 x D | 25 | – | 40 | fz | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,054 | 0,061 | |

| 3 | 1,5 x D | 0,5 x D | 1 x D | 25 | – | 40 | fz | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,054 | 0,061 | |

| 4 | 1,5 x D | 0,5 x D | 1 x D | 50 | – | 60 | fz | 0,045 | 0,052 | 0,058 | 0,064 | 0,069 | 0,074 | 0,084 | |

| H | 1 | 1,5 x D | 0,5 x D | 0,75 x D | 80 | – | 140 | fz | 0,054 | 0,062 | 0,070 | 0,077 | 0,083 | 0,088 | 0,098 |

| 2 | 1,5 x D | 0,2 x D | 0,5 x D | 70 | – | 120 | fz | 0,040 | 0,047 | 0,052 | 0,057 | 0,061 | 0,065 | 0,071 | |