Product Similar To:

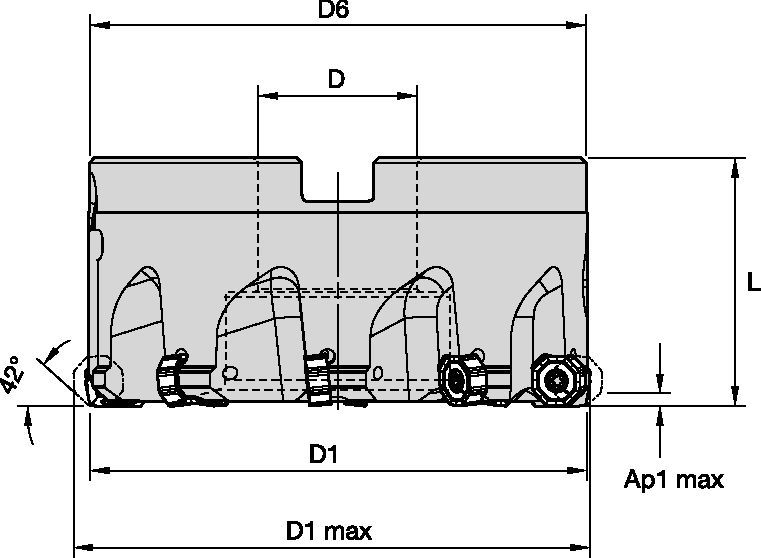

M1600 Mini-F • 42° • Shell Mills • Metric

Shell Mills • Cast Iron Finishing

Material Number5626418

ISO Catalog IDM1600D160Z16W4S40ON04ANSI Catalog IDM1600D160Z16W4S40ON04

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Face Milling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5626418 |

| ISO Catalog ID | M1600D160Z16W4S40ON04 |

| ANSI Catalog ID | M1600D160Z16W4S40ON04 |

| [D1] Effective Cutting Diameter | 160 mm |

| [D1] Effective Cutting Diameter | 6.299 in |

| [D1MAX] Maximum Cutting Diameter | 166.445 mm |

| [D1MAX] Maximum Cutting Diameter | 6.553 in |

| [D] Adapter / Shank / Bore Diameter | 40 mm |

| [D] Adapter / Shank / Bore Diameter | 1.574 in |

| [D6] Hub Diameter | 90 mm |

| [D6] Hub Diameter | 3.543 in |

| [L] Overall Length | 63 mm |

| [L] Overall Length | 2.48 in |

| [AP1MAX] 1st Maximum Cutting Depth | 2.1 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .0827 in |

| Number of Inserts | 16 |

| Max RPM | 5700 |

| Coolant Supply | N |

| Weight Kilograms | 6.4 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Uses and application

Face Milling

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| Light | General | Heavy | ||||

| Material | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .S..MM | WU10PM | .S..MM | WU10PM | .S..MM | WU20PM |

| P3–P4 | .S..MM | WU10PM | .S..MM | WU20PM | .S..MM | WU20PM |

| P5–P6 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| M1–M2 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| M3 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| K1–K2 | .S..MM | WK15CM | .S..MM | WK15CM | .S..MM | WU20PM |

| K3 | .S..MM | WU20PM | .S..MM | WU10PM | .S..MM | WK15CM |

| N1–N2 | .S..MM | WU10PM | .S..MM | WU10PM | .S..MM | WU20PM |

| N3 | .S..MM | WU10PM | .S..MM | WU10PM | .S..MM | WU20PM |

| S1–S2 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| S3 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| S4 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| H1 | .S..MM | WU10PM | .S..MM | WU20PM | .S..MM | WU20PM |

Feeds

| Light | General | Heavy |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .S..MM | 0,17 | 0,61 | 1,23 | 0,12 | 0,44 | 0,88 | 0,09 | 0,33 | 0,66 | 0,08 | 0,29 | 0,57 | 0,07 | 0,26 | 0,52 | .S..MM |

| Light | General | Heavy |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40-100% | ||||||||||||

| .S..MM | .007 | .023 | .046 | .005 | .016 | .033 | .004 | .012 | .024 | .003 | .011 | .021 | .003 | .010 | .019 | .S..MM |

Speeds

| Material Group | WK15CM | WU10PM | WU20PM | THM-F | |||||||||

| P | 1 | — | — | — | — | — | — | 330 | 290 | 270 | — | — | — |

| 2 | — | — | — | — | — | — | 275 | 250 | 200 | — | — | — | |

| 3 | — | — | — | — | — | — | 255 | 220 | 175 | — | — | — | |

| 4 | — | — | — | 245 | 200 | 170 | 225 | 190 | 150 | — | — | — | |

| 5 | — | — | — | — | — | — | 185 | 175 | 150 | — | — | — | |

| 6 | — | — | — | — | — | — | 165 | 130 | 100 | — | — | — | |

| M | 1 | — | — | — | — | — | — | 205 | 180 | 165 | — | — | — |

| 2 | — | — | — | — | — | — | 185 | 160 | 130 | — | — | — | |

| 3 | — | — | — | — | — | — | 140 | 120 | 95 | — | — | — | |

| K | 1 | 420 | 385 | 340 | 295 | 265 | 240 | 250 | 220 | 185 | 190 | 170 | 150 |

| 2 | 335 | 295 | 275 | 230 | 205 | 190 | 200 | 180 | 150 | — | — | — | |

| 3 | 280 | 250 | 230 | 195 | 175 | 160 | 180 | 150 | 120 | — | — | — | |

| N | 1 | — | — | — | 640 | 570 | 525 | 550 | 470 | 400 | 795 | 695 | 600 |

| 2 | — | — | — | 640 | 570 | 525 | 550 | 470 | 400 | 795 | 695 | 600 | |

| 3 | — | — | — | 580 | 535 | 490 | 400 | 350 | 300 | — | — | — | |

| S | 1 | — | — | — | — | — | — | 40 | 35 | 25 | — | — | — |

| 2 | — | — | — | — | — | — | 40 | 35 | 25 | — | — | — | |

| 3 | — | — | — | — | — | — | 50 | 40 | 25 | — | — | — | |

| 4 | — | — | — | — | — | — | 70 | 50 | 35 | — | — | — | |

| H | 1 | — | — | — | 160 | 130 | 90 | 110 | 80 | 70 | — | — | — |

| Material Group | WK15CM | WU10PM | WU20PM | THM-F | |||||||||

| P | 1 | — | — | — | — | — | — | 1080 | 950 | 890 | — | — | — |

| 2 | — | — | — | — | — | — | 900 | 820 | 660 | — | — | — | |

| 3 | — | — | — | — | — | — | 840 | 720 | 570 | — | — | — | |

| 4 | — | — | — | 800 | 660 | 560 | 740 | 620 | 490 | — | — | — | |

| 5 | — | — | — | — | — | — | 610 | 570 | 490 | — | — | — | |

| 6 | — | — | — | — | — | — | 540 | 430 | 330 | — | — | — | |

| M | 1 | — | — | — | — | — | — | 670 | 590 | 540 | — | — | — |

| 2 | — | — | — | — | — | — | 610 | 520 | 430 | — | — | — | |

| 3 | — | — | — | — | — | — | 460 | 390 | 310 | — | — | — | |

| K | 1 | 1380 | 1260 | 1120 | 970 | 870 | 790 | 820 | 720 | 610 | 620 | 560 | 490 |

| 2 | 1100 | 970 | 900 | 750 | 670 | 620 | 660 | 590 | 490 | — | — | — | |

| 3 | 920 | 820 | 750 | 640 | 570 | 520 | 590 | 490 | 390 | — | — | — | |

| N | 1 | — | — | — | 2100 | 1870 | 1720 | 1800 | 1540 | 1310 | 2610 | 2280 | 1970 |

| 2 | — | — | — | 2100 | 1870 | 1720 | 1800 | 1540 | 1310 | 2610 | 2280 | 1970 | |

| 3 | — | — | — | 1900 | 1760 | 1610 | 1310 | 1150 | 980 | — | — | — | |

| S | 1 | — | — | — | — | — | — | 130 | 110 | 80 | — | — | — |

| 2 | — | — | — | — | — | — | 130 | 110 | 80 | — | — | — | |

| 3 | — | — | — | — | — | — | 160 | 130 | 80 | — | — | — | |

| 4 | — | — | — | — | — | — | 230 | 160 | 110 | — | — | — | |

| H | 1 | — | — | — | 520 | 430 | 300 | 360 | 260 | 230 | — | — | — |

I have read and accepted the Terms & Conditions of use