Product Similar To:

TOP DRILL Deep Hole • 30 x D • TDD108 • 2 Flute

TDD108 • 30 x D • Metric

Material Number3899593

ISO Catalog IDTDD108Z06800ANSI Catalog IDTDD108Z06800

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Drilling

Drilling: Stacked Plates

Drilling - Through Coolant

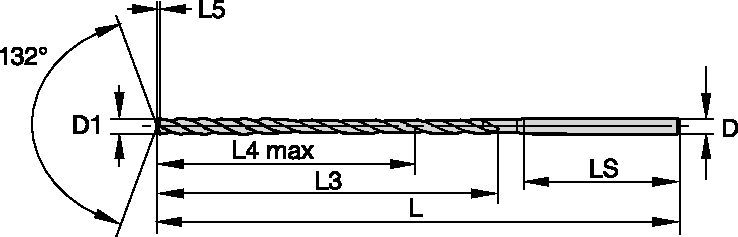

Tool Dimensions: 2flute/4margin/coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3899593 |

| ISO Catalog ID | TDD108Z06800 |

| ANSI Catalog ID | TDD108Z06800 |

| Grade | WU20PD |

| [D1] Drill Diameter M | 6.8 mm |

| [D1] Drill Diameter M | 0.2677 in |

| [D] Adapter / Shank / Bore Diameter | 7 mm |

| [D] Adapter / Shank / Bore Diameter | 0.2756 in |

| [L3] Flute Length | 222 mm |

| [L3] Flute Length | 8.7402 in |

| [L4] Maximum Drilling Depth | 206 mm |

| [L4] Maximum Drilling Depth | 8.1102 in |

| [L5] Drill Point Length | 1.421 mm |

| [L5] Drill Point Length | 0.0559 in |

| [LS] Shank Length | 38 mm |

| [LS] Shank Length | 1.4961 in |

| [L] Overall Length | 267 mm |

| [L] Overall Length | 10.5118 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Uses and application

Drilling

Drilling: Stacked Plates

Drilling - Through Coolant

Tool Dimensions: 2flute/4margin/coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Grades

WU20PD

Composition: With a multilayered PVD TiN-TiAlN coating, a high-quality, sub-micron, carbide substrate and a state-of-the-art surface condition, this grade gives the highest level of wear resistance at high cutting speeds.

Application: First choice for alloyed and high-alloyed steels and cast irons. A state-of-the-art surface condition enables superior chip evacuation even when MQL is applied.

Features and benefits

- Standard items listed. Additional diameters and lengths made to order.

- For information about Custom Solutions, such as multi-step drills, see page [REFERENCE].

- For information about Reconditioning Services, see page [REFERENCE].

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Metric | |||

| tolerance | |||

| nominal size range | D1 tolerance | D1 tolerance | D tolerance h6 |

| 0,000/-0,012 | 0,000/-0,008 | ||

| 0,000/-0,015 | 0,000/-0,009 | ||

| 0,000/-0,018 | 0,000/-0,011 | ||

Application Data • TDD Series • WU20PD™ • Through Coolant • Metric

| Inch | |||

| tolerance | |||

| D1 | D1 tolerance m7 | D | D tolerance h6 |

| .0000/-.0005 | .0000/-.0003 | ||

| .0000/-.0006 | .0000/-.0004 | ||

| .0000/-.0007 | .0000/-.0004 | ||

I have read and accepted the Terms & Conditions of use