Product Similar To:

Finishers • Series 4C05 4C15 • Sharp Edge • Inch

Series 4C05 4C15 • Inch

Material Number2831592

ISO Catalog IDTR4C4507002ANSI Catalog IDTR4C4507002

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Ramping: Blank

Corner Style: Square End

Shank - Cylindrical Plain

Side Milling/Shoulder Milling: Square End

Helix Angle: 45°

Tool Dimensions: Flute Configuration: 5

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 2831592 |

| ISO Catalog ID | TR4C4507002 |

| ANSI Catalog ID | TR4C4507002 |

| Grade | WP15PE |

| Adapter Style Machine Side | Straight-Cylindrical |

| [Z] Number of Flutes | 5 |

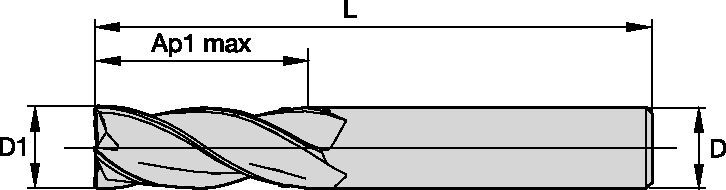

| [D1] Effective Cutting Diameter | 6.35 mm |

| [D1] Effective Cutting Diameter | .25 in |

| [D] Adapter / Shank / Bore Diameter | 6.35 mm |

| [D] Adapter / Shank / Bore Diameter | .25 in |

| [AP1MAX] 1st Maximum Cutting Depth | 9.525 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .375 in |

| [L] Overall Length | 50.8 mm |

| [L] Overall Length | 2 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Ramping: Blank

Corner Style: Square End

Shank - Cylindrical Plain

Side Milling/Shoulder Milling: Square End

Helix Angle: 45°

Tool Dimensions: Flute Configuration: 5

Grades

WP15PE

Coated carbide grade with thick PVD coating and optimized chemistry and process for increased wear resistance. Outstanding protection in milling of steels to mitigate crater, DOCN (depth-of-cut notching), and flank wear. Excellent performance up to 52 HRC.

Features and benefits

- Center cutting

- Standard items listed and additional styles and coatings made-to-order

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

Series 4C05 4C15 • Victory Grades

|  | |||||||||||||||

| Side Milling (A) | WP15PE | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||||

| A | Cutting Speed | D1 | ||||||||||||||

| frac. | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| Material | ap | ae | Min | Max | dec. | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| P | 0 | Ap1 max | 0.1 x D | 490 | – | 660 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 1 | Ap1 max | 0.1 x D | 490 | – | 660 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 | |

| 2 | Ap1 max | 0.1 x D | 460 | – | 620 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 | |

| 3 | Ap1 max | 0.1 x D | 390 | – | 520 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 max | 0.1 x D | 300 | – | 490 | IPT | .0007 | .0010 | .0014 | .0017 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| 5 | Ap1 max | 0.1 x D | 200 | – | 330 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| 6 | Ap1 max | 0.1 x D | 160 | – | 250 | IPT | .0005 | .0008 | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| M | 1 | Ap1 max | 0.1 x D | 300 | – | 380 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 max | 0.1 x D | 200 | – | 260 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| 3 | Ap1 max | 0.1 x D | 200 | – | 230 | IPT | .0005 | .0008 | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| K | 1 | Ap1 max | 0.1 x D | 390 | – | 490 | IPT | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 2 | Ap1 max | 0.1 x D | 360 | – | 460 | IPT | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 3 | Ap1 max | 0.1 x D | 360 | – | 430 | IPT | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| H | 1 | Ap1 max | 0.1 x D | 260 | – | 460 | IPT | .0007 | .0010 | .0014 | .0017 | .0020 | .0026 | .0030 | .0034 | .0039 |

| 2 | Ap1 max | 0.1 x D | 230 | – | 390 | IPT | .0005 | .0008 | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

I have read and accepted the Terms & Conditions of use