Product Similar To:

VNMG-RH • Roughing

VNMG-RH

Material Number4171552

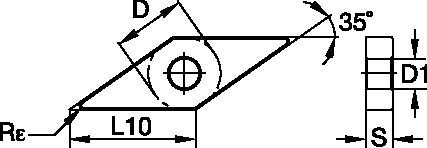

ISO Catalog IDVNMG220412RHANSI Catalog IDVNMG433RH

- P Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4171552 |

| ISO Catalog ID | VNMG220412RH |

| ANSI Catalog ID | VNMG433RH |

| Grade | WP25CT |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | .5 in |

| [L10] Insert Cutting Edge Length | 22.142 mm |

| [L10] Insert Cutting Edge Length | .8717 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | .1875 in |

| [Rε] Corner Radius | 1.2 mm |

| [Rε] Corner Radius | .0468 in |

| [D1] Insert Hole Size | 5.16 mm |

| [D1] Insert Hole Size | .2031 in |

Workpiece Materials

- Steel

- Cast Iron

Grades

WP25CT

A tough cobalt-enriched carbide grade with a newly designed multilayer K-MTCVD TiCN-Al2O3-TiCNTiN coating with superior interlayer adhesion. This is the industry’s best general-purpose turning grade for most steels and ferritic and martensitic stainless steels. The substrate design, with cobalt-enrichment, ensures adequate deformation resistance along with excellent bulk toughness and insert edge strength. The coating layers offer good wear resistance over a wide range of machining conditions. The smoothness of the coating leads to reduced frictional heat, minimizes microchipping, and improves workpiece surface finishes.

Features and benefits

- For deep groove and cut-off applications

- Universal pocket for holding all insert geometries

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use