Produkt ähnlich wie:

M680-16 • Weldon® Schaftfräser • metrisch

Schaftfräser mit Weldon Zylinderschaft • Metrisch

Material Nummer2002369

ISO Katalog Nummer12396920600ANSI Katalog Nummer12396920600

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- N NE-Metalle

- S Hochwarmfeste Legierungen

- H Gehärtete Werkstoffe

Planfräsen

Nutenfräsen: Ebene Stirnfläche

Zylinderschaft – Weldon, 2 Spannflächen

Side Milling/Shoulder Milling: Square End

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Überblick

- Anwendungsdaten

- Herunterladen

- Kompatible Teile Maschinenseite

- Kompatible Teile Werkstückseite

- Ersatzteile

- Bewertung

- F&A

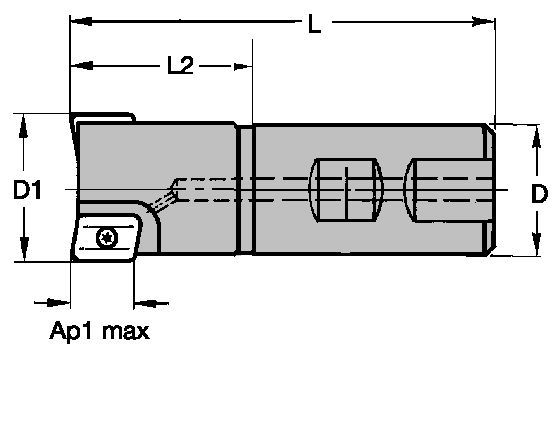

| Material Nummer | 2002369 |

| ISO Katalog Nummer | 12396920600 |

| ANSI Katalog Nummer | 12396920600 |

| Sorte | W |

| [D1] Effektiver Schneidendurchmesser | 20 mm |

| [D1] Effektiver Schneidendurchmesser | .787 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 20 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | .7874 in |

| [L] Gesamtlänge | 82 mm |

| [L] Gesamtlänge | 3.228 in |

| [L2] Kopflänge | 32 mm |

| [L2] Kopflänge | 1.26 in |

| [AP1MAX] 1. maximale Schnitttiefe | 9 mm |

| [AP1MAX] 1. maximale Schnitttiefe | .354 in |

| Anzahl der Schneidkörper | 2 |

| Max. Drehzahl | 27000 |

| Kühlmittelzubehör | Y |

| Gewicht Kilogramm | 0.3 |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- NE-Metalle

- Hochwarmfeste Legierungen

- Gehärtete Werkstoffe

Uses and application

Planfräsen

Nutenfräsen: Ebene Stirnfläche

Zylinderschaft – Weldon, 2 Spannflächen

Side Milling/Shoulder Milling: Square End

Features and benefits

- WU20PE grade

- Variable helix to reduce vibrations and increase overall stability

- Asymmetrical pitch to cut harmonics and reduce vibrations

- Eccentric relief to provide vibration dampening and increase tool life on steel, stainless steel and cast iron

- Core taper to increase tool stability and chip evacuation

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Insert Selection

Auswahlhilfe für Wendeschneidplatten

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte | |

| P1–P2 | XPHT-GE | WP40PM | XPHT.. | WP40PM | XPHT.. | WP40PM |

| P3–P4 | XPHT-GE | TN6540 | XPHT.. | WP40PM | XPHT.. | WP40PM |

| P5–P6 | XPHT-GE | TN6540 | XPHT.. | WP40PM | XPHT.. | WP40PM |

| M1–M2 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| M3 | XPHT-GE | TN7535 | XPHT.. | WP40PM | XPHT-MR | TN7535 |

| K1–K2 | XPHT-GE | TN6510 | XPHT.. | TN6520 | XPHT-MR | WK15CM |

| K3 | XPHT-GE | TN6510 | XPHT.. | TN7535 | XPHT-MR | WK15CM |

| N1–N2 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 |

| N3 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 | XPHT-ALP | TN6501 |

| S1–S2 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| S3 | XPHT-GE | WS30PM | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| S4 | XPHT-GE | TN6540 | XPHT.. | TN6540 | XPHT-MR | TN6540 |

| H1 | XPHT-GE | WS30PM | XPHT.. | TN6540 | XPHT-MR | TN6540 |

Feeds

Empfohlene Startwerte für Vorschübe [mm]

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Programmierter Vorschub pro Zahn (fz) | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| XPHT-ALP | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | XPHT-ALP |

| XPHT-GE | 0,19 | 0,47 | 0,70 | 0,14 | 0,34 | 0,50 | 0,11 | 0,26 | 0,38 | 0,09 | 0,22 | 0,33 | 0,08 | 0,20 | 0,30 | XPHT-GE |

| XPHT.. | 0,22 | 0,56 | 0,82 | 0,16 | 0,40 | 0,59 | 0,12 | 0,30 | 0,44 | 0,10 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | XPHT.. |

| XPNT.. | 0,22 | 0,56 | 0,82 | 0,16 | 0,40 | 0,59 | 0,12 | 0,30 | 0,44 | 0,10 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | XPNT.. |

| XPHT-MR | 0,23 | 0,59 | 0,92 | 0,17 | 0,43 | 0,66 | 0,13 | 0,32 | 0,50 | 0,11 | 0,28 | 0,43 | 0,10 | 0,25 | 0,40 | XPHT-MR |

Recommended Starting Feeds [IPT]

| Schneidkörper- Geometrie | Programmierter Vorschub pro Zahn (fz) | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | .005 | .014 | .022 | .003 | .010 | .016 | .003 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .010 | .F..ALP |

| .E..AL | .005 | .014 | .022 | .003 | .010 | .016 | .003 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .010 | .E..AL |

| .E..GE | .008 | .018 | .027 | .005 | .013 | .020 | .004 | .010 | .015 | .004 | .009 | .013 | .003 | .008 | .012 | .E..GE |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Speeds

Empfohlene Start-Schnittgeschwindigkeiten [m/min]

| Werkstoffgruppe | THR | THM-U | TN6501 | TN6502 | TN6510 | TN6520 | TN6525 | TN6540 | |||||||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 |

| 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | |

| K | 1 | 150 | 135 | 120 | 190 | 170 | 150 | – | – | – | – | – | – | 400 | 290 | 215 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 |

| 2 | 185 | 140 | 120 | – | – | – | – | – | – | – | – | – | 350 | 235 | 170 | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | |

| 3 | 105 | 75 | 50 | – | – | – | – | – | – | – | – | – | 280 | 215 | 165 | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | |

| N | 1 | 900 | 600 | 500 | 2000 | 1200 | 1000 | 2000 | 1200 | 1000 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | 1365 | 815 | 665 | 1365 | 815 | 665 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | 800 | 500 | 400 | 800 | 500 | 400 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 35 | 25 | 20 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 30 | 25 |

| 2 | 25 | 20 | 15 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 20 | 15 | 10 | |

| 3 | 50 | 40 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 35 | 25 | |

| 4 | 35 | 25 | 18 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 25 | 20 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Werkstoffgruppe | TTM08 | WK15PM | WP35CM | WU20PM | TTI25 | THM | WK15CM | WP40PM | WS30PM | |||||||||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | 360 | 300 | 250 | – | – | – | – | – | – | 295 | 260 | 245 | – | – | – |

| 1 | 230 | 200 | 190 | – | – | – | 455 | 395 | 370 | 330 | 290 | 270 | 360 | 300 | 250 | – | – | – | – | – | – | 295 | 260 | 245 | – | – | – | |

| 2 | 195 | 170 | 140 | – | – | – | 280 | 255 | 230 | 275 | 250 | 200 | 260 | 210 | 180 | – | – | – | – | – | – | 250 | 215 | 180 | – | – | – | |

| 3 | 180 | 150 | 125 | – | – | – | 255 | 230 | 205 | 255 | 220 | 175 | 260 | 210 | 180 | – | – | – | – | – | – | 230 | 195 | 160 | – | – | – | |

| 4 | 160 | 130 | 105 | – | – | – | 190 | 175 | 160 | 225 | 190 | 150 | 220 | 180 | 150 | – | – | – | – | – | – | 205 | 170 | 135 | – | – | – | |

| 5 | – | – | – | – | – | – | 260 | 230 | 210 | 185 | 175 | 150 | 265 | 195 | 165 | – | – | – | – | – | – | 170 | 155 | 135 | – | – | – | |

| 6 | – | – | – | – | – | – | 160 | 135 | 110 | 165 | 130 | 100 | 120 | 90 | 75 | – | – | – | – | – | – | 150 | 115 | 90 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 205 | 185 | 155 | 205 | 180 | 165 | 400 | 260 | 180 | – | – | – | – | – | – | 195 | 170 | 155 | 225 | 200 | 185 |

| 2 | – | – | – | – | – | – | 185 | 160 | 140 | 185 | 160 | 130 | 270 | 170 | 120 | – | – | – | – | – | – | 175 | 150 | 125 | 205 | 180 | 145 | |

| 3 | – | – | – | – | – | – | 145 | 130 | 115 | 140 | 120 | 95 | 265 | 175 | 120 | – | – | – | – | – | – | 130 | 115 | 90 | 155 | 135 | 105 | |

| K | 1 | – | – | – | 400 | 290 | 215 | 295 | 265 | 240 | 250 | 220 | 185 | 185 | 155 | 130 | – | – | – | 420 | 385 | 340 | – | – | – | – | – | – |

| 2 | – | – | – | 350 | 235 | 170 | 235 | 210 | 190 | 200 | 180 | 150 | 150 | 120 | 105 | – | – | – | 335 | 295 | 275 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 215 | 165 | 195 | 175 | 160 | 180 | 150 | 120 | 120 | 105 | 85 | – | – | – | 280 | 250 | 230 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | 795 | 695 | 600 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | 795 | 695 | 600 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 400 | 350 | 300 | – | – | – | 560 | 485 | 420 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 |

| 2 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | |

| 3 | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | |

| 4 | – | – | – | – | – | – | 66 | 50 | 33 | 70 | 50 | 35 | – | – | – | – | – | – | – | – | – | 65 | 50 | 35 | 85 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | – | – | – | 110 | 80 | 70 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | THM | THM-U | THR | TN6501 | TN6502 | TN6510 | TN6520 | TN6525 | |||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1345 | 1050 | 920 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1050 | 820 | 705 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 920 | 705 | 605 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 770 | 560 | 475 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1015 | 770 | 640 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 670 | 525 | 425 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 625 | 395 | 260 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 395 | 260 | 165 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 410 | 260 | 180 | |

| K | 1 | 390 | 295 | 245 | 620 | 555 | 490 | 490 | 440 | 390 | – | – | – | – | – | – | 1575 | 1150 | 835 | 1475 | 1050 | 755 | – | – | – |

| 2 | 410 | 325 | 225 | – | – | – | 605 | 455 | 390 | – | – | – | – | – | – | 1380 | 920 | 670 | 1280 | 820 | 625 | – | – | – | |

| 3 | 425 | 310 | 195 | – | – | – | 340 | 245 | 160 | – | – | – | – | – | – | 1100 | 855 | 655 | 985 | 740 | 525 | – | – | – | |

| N | 1 | 2950 | 1965 | 1640 | 6560 | 3935 | 3280 | 2950 | 1965 | 1640 | 6560 | 3935 | 3280 | 5245 | 3115 | 2620 | – | – | – | – | – | – | – | – | – |

| 2 | 2245 | 1525 | 1260 | 4475 | 2670 | 2180 | 2245 | 1525 | 1260 | 4475 | 2670 | 2180 | 3605 | 2180 | 1800 | – | – | – | – | – | – | – | – | – | |

| 3 | 1475 | 915 | 655 | 2620 | 1640 | 1310 | 1475 | 915 | 655 | 2620 | 1640 | 1310 | 2130 | 1310 | 980 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 110 | 80 | 65 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 80 | 65 | 45 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 160 | 130 | 95 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 110 | 80 | 55 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Werkstoffgruppe | TN6540 | TTI25 | TTM08 | WK15CM | WK15PM | WP35CM | WP40PM | WS30PM | WU20PM | |||||||||||||||||||

| P | 1 | 1180 | 920 | 785 | 1180 | 985 | 820 | 750 | 655 | 620 | – | – | – | – | – | – | 1490 | 1295 | 1210 | 970 | 855 | 805 | 1215 | 1050 | 985 | 1080 | 950 | 885 |

| 2 | 820 | 625 | 540 | 855 | 690 | 590 | 635 | 555 | 455 | – | – | – | – | – | – | 915 | 835 | 750 | 820 | 705 | 590 | 1000 | 885 | 720 | 900 | 820 | 655 | |

| 3 | 705 | 540 | 460 | 855 | 690 | 590 | 590 | 490 | 410 | – | – | – | – | – | – | 835 | 750 | 670 | 755 | 640 | 525 | 935 | 785 | 640 | 835 | 720 | 570 | |

| 4 | 590 | 425 | 360 | 720 | 590 | 490 | 520 | 425 | 340 | – | – | – | – | – | – | 620 | 570 | 520 | 670 | 560 | 445 | 820 | 670 | 540 | 735 | 620 | 490 | |

| 5 | 785 | 590 | 490 | 870 | 640 | 540 | – | – | – | – | – | – | – | – | – | 850 | 750 | 685 | 560 | 510 | 445 | 670 | 625 | 540 | 605 | 570 | 490 | |

| 6 | 525 | 395 | 330 | 395 | 295 | 245 | – | – | – | – | – | – | – | – | – | 520 | 440 | 360 | 490 | 375 | 295 | 605 | 460 | 360 | 540 | 425 | 325 | |

| M | 1 | 425 | 260 | 195 | 1310 | 855 | 590 | – | – | – | – | – | – | – | – | – | 670 | 605 | 505 | 640 | 560 | 510 | 740 | 655 | 605 | 670 | 590 | 540 |

| 2 | 260 | 165 | 130 | 885 | 560 | 395 | – | – | – | – | – | – | – | – | – | 605 | 520 | 455 | 575 | 490 | 410 | 670 | 590 | 475 | 605 | 520 | 425 | |

| 3 | 280 | 165 | 130 | 870 | 575 | 395 | – | – | – | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 510 | 445 | 345 | 455 | 390 | 310 | |

| K | 1 | – | – | – | 605 | 510 | 425 | – | – | – | 1380 | 1265 | 1115 | 1310 | 950 | 705 | 965 | 865 | 785 | – | – | – | 835 | 740 | 640 | 820 | 720 | 605 |

| 2 | – | – | – | 490 | 395 | 345 | – | – | – | 1100 | 970 | 900 | 1145 | 770 | 555 | 770 | 685 | 620 | – | – | – | 655 | 590 | 540 | 655 | 590 | 490 | |

| 3 | – | – | – | 395 | 345 | 280 | – | – | – | 920 | 820 | 755 | 915 | 800 | 540 | 635 | 570 | 520 | – | – | – | 540 | 490 | 445 | 590 | 490 | 390 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1310 | 1145 | 980 | |

| S | 1 | 150 | 115 | 100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 130 | 110 | 80 |

| 2 | 80 | 65 | 35 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 130 | 110 | 80 | |

| 3 | 230 | 130 | 100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 180 | 150 | 100 | 160 | 130 | 80 | |

| 4 | 195 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 215 | 160 | 105 | 215 | 165 | 115 | 280 | 195 | 130 | 225 | 160 | 110 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 445 | 330 | 245 | 360 | 260 | 225 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use