Heat Exchangers Machining Solutions

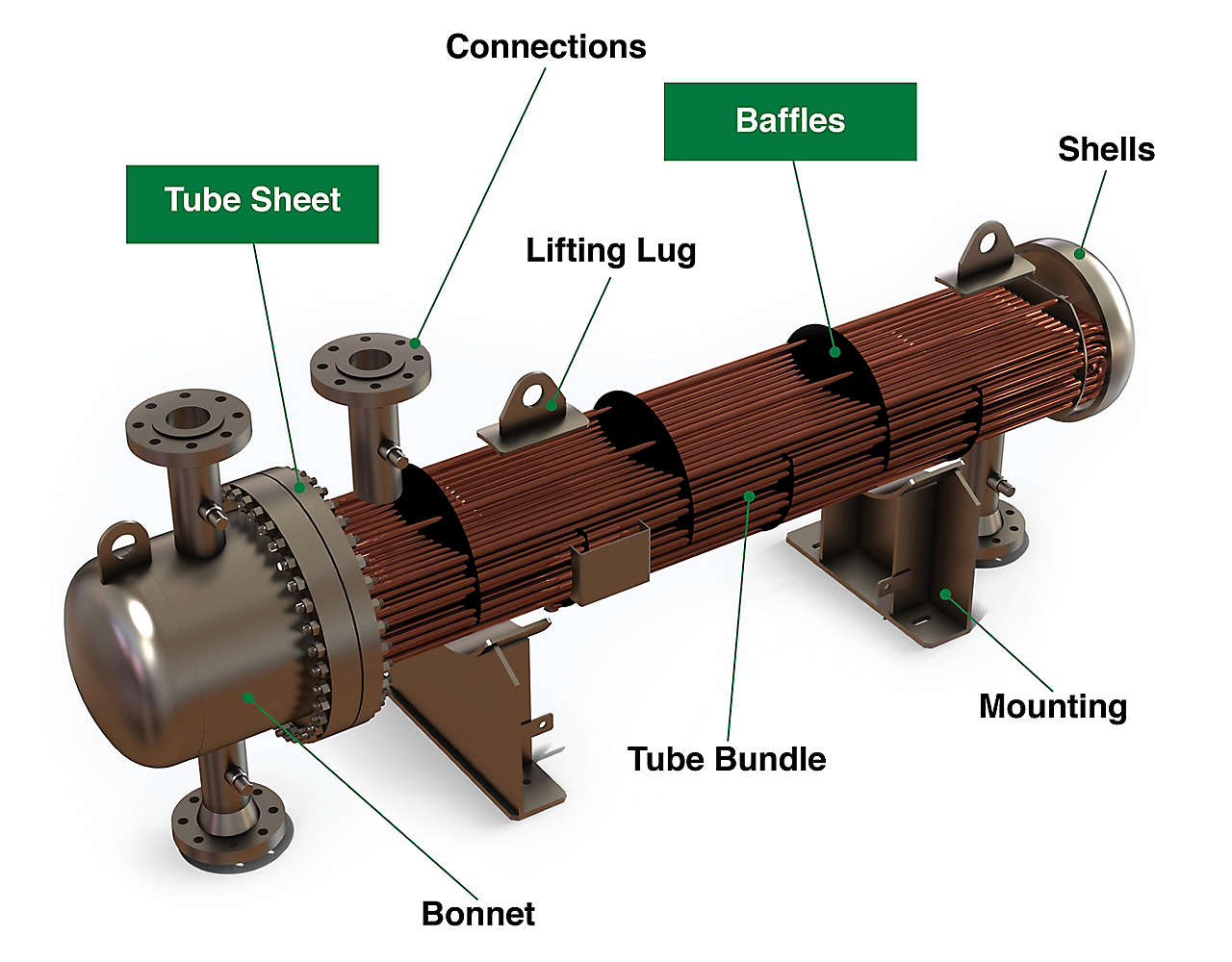

The tube sheet is one of the main components in a shell & tube heat exchanger.

Depending on the tube bundle configuration, a heat exchanger can be equipped with one or two tube sheets.

These are usually made of low carbon steel material, with a varying thickness based on the fluid pressure.

Depending on the final application (petrochemical, nuclear, oil&gas, etc.) the tube sheet can be cladded with Stainless Steel or other Super Alloys or even be entirely made out Stainless Steel or Superalloys.

Tube Sheets

The tube sheet is one of the main components in a shell & tube heat exchanger.

Depending on the tube bundle configuration, a heat exchanger can be equipped with one or two tube sheets.

These are usually made of low carbon steel material, with a varying thickness based on the fluid pressure.

Depending on the final application (petrochemical, nuclear, oil&gas, etc.) the tube sheet can be cladded with Stainless Steel or other Super Alloys or even be entirely made out Stainless Steel or Superalloys.

Typical Hole Patterns

The most common types of holes experienced in tube sheet drilling are triangular, rotated triangular, square and rotated square. Each hole pattern presents its own drilling challenges. See typical pattern types below.

Material Configuration