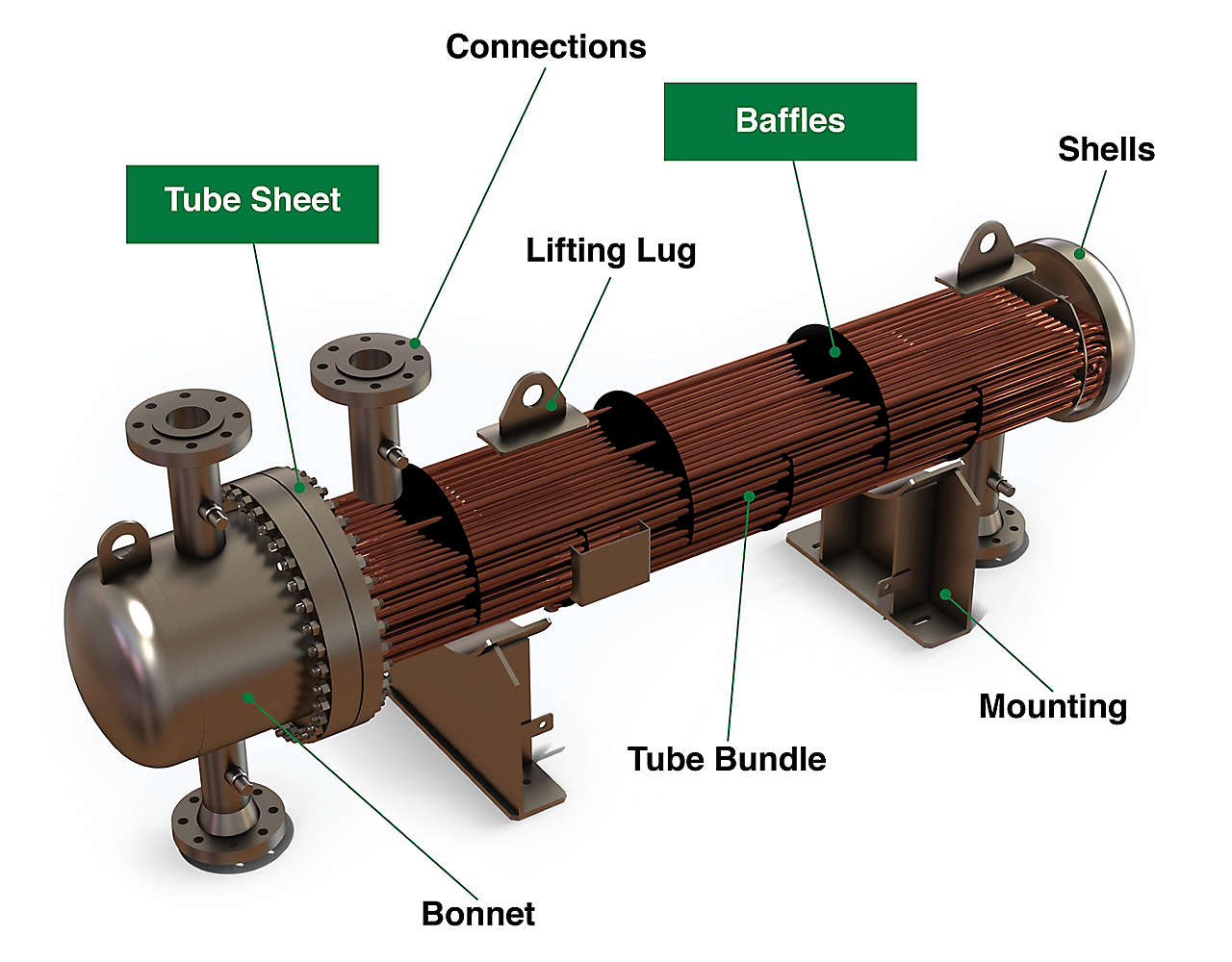

Heat Exchanger Baffles

The baffles are thin plates positioned for the entire length of the tube bundle.

They have two primary functions:

- Sustain the tube bundles

- Increase the heat-transfer by changing the flow of the fluid and generating turbulence

Baffles have generally a thickness between 10mm to 20mm and they are usually machined in stacks of 2 to 5 plates, making the drilling operation more complex.

Baffles

The baffles are thin plates positioned for the entire length of the tube bundle.

They have two primary functions:

- Sustain the tube bundles

- Increase the heat-transfer by changing the flow of the fluid and generating turbulence

Baffles have generally a thickness between 10mm to 20mm and they are usually machined in stacks of 2 to 5 plates, making the drilling operation more complex.

Typical Baffle Geometries

Single Segmented Baffles

Double Segmented Baffles

Disc and Donut Baffles

Baffle Drilling

- Baffles are generally drilled in stacks from 2 - 5 plates

- Single plate thickness vary from 10mm - 20mm

- Welding the plates together can increase stability

Challenges in Baffle Drilling:

- Uneven surface

- Space between the plates

- Instability

- Disc generated at the hole exit between the plates

Proven Machining Operations

Drilling

Tubesheets have different sizes and a series of holes are done to create a place where the tube ends are welded.

Depending on the hole size and plate material, WIDIA can cover this application with TDMX, TC4 and VariDrill

Drilling of Stacked Plates

Baffles are generally machined in stacks of 2 to 5 plates. Common material is low carbon steel. To face this application with confidence WIDIA offers the TDMX Modular Drilling platform, in combination with the flat bottom insert geometry FPE

Hole Finishing

If necessary, WIDIA is capable of covering fine finishing operations with the TRF / TRM product series

Turning

To remove the surface impurity on tube sheets, these are machined with a turning operation. WIDIA offers a wide range of Heavy duty inserts, as well as ISO turning inserts to cover all the most common materials