Producto similar a:

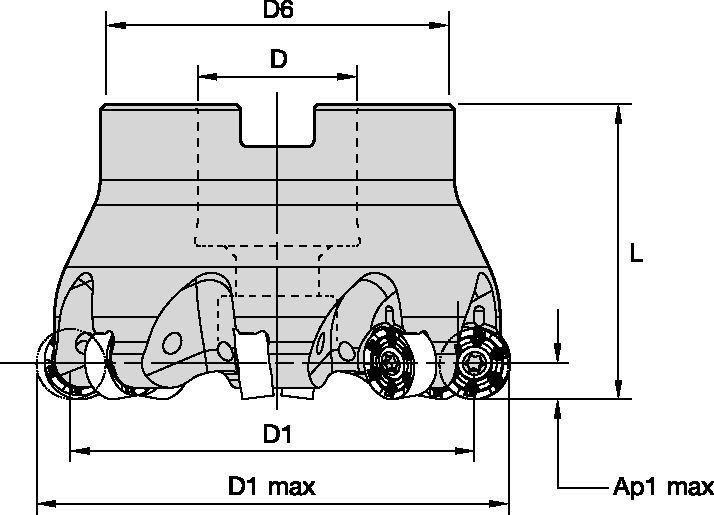

M200 • RN.J16... • Fresas de plato • Sistema métrico

IC16 • Fresas de plato

Número de material5209989

Referencia ISOM200D50Z04RN16Referencia ANSIM200D50Z04RN16

- P Acero

- M Acero inoxidable

- K Fundición

- N Materiales no ferrosos

- S Aleaciones de alta temperatura

- H Materiales endurecidos

Planeado

Ranurado: Placa cuadrada

Fresado lateral/Fresado en escuadra: Nariz de bola

Perfilado 3D

Fresado — Con refrigeración interna

Fresado — lateral y planeado

Mecanizado de alojamientos

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Piezas compatibles Lado de la pieza

- Piezas de recambio

- Comentarios

- Preguntas y Respuestas

| Número de material | 5209989 |

| Referencia ISO | M200D50Z04RN16 |

| Referencia ANSI | M200D50Z04RN16 |

| Diámetro de corte máximo [D1MAX] | 50 mm |

| Diámetro de corte máximo [D1MAX] | 1.969 in |

| Diámetro de corte efectivo [D1] | 34 mm |

| Diámetro de corte efectivo [D1] | 1.339 in |

| Adaptador/Mango/Diá int [D] | 22 mm |

| Adaptador/Mango/Diá int [D] | .866 in |

| Diámetro de núcleo [D6] | 42 mm |

| Diámetro de núcleo [D6] | 1.654 in |

| Longitud total [L] | 50 mm |

| Longitud total [L] | 1.969 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 3.97 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | .156 in |

| Número de plaquitas | 4 |

| Ángulo de vaciado máximo | 0.49 |

| RPM máx. | 26700 |

| Suministro de refrigerante | Y |

| Peso en kilogramos | 0.36 |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Materiales no ferrosos

- Aleaciones de alta temperatura

- Materiales endurecidos

Uses and application

Planeado

Ranurado: Placa cuadrada

Fresado lateral/Fresado en escuadra: Nariz de bola

Perfilado 3D

Fresado — Con refrigeración interna

Fresado — lateral y planeado

Mecanizado de alojamientos

Features and benefits

- 12 filos de corte, doble cara.

- Función antirrotación para una mejor estabilidad y mayores avances.

- Capacidades de mecanizado de alojamientos y perfilado.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Insert Selection

Guía para la selección de plaquitas

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | ||||

| Grupo de materiales | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | ML | WP25PM | MM | WP40PM | MM | WP40PM |

| P3–P4 | ML | WP25PM | MM | WP25PM | MH | WP40PM |

| P5–P6 | ML | WP35CM | MM | WP35CM | MH | WP35CM |

| M1–M2 | ML | WP25PM | ML | WU35PM | MM | WU35PM |

| M3 | ML | WP25PM | MM | WU35PM | MM | WU35PM |

| K1–K2 | MH | WK15CM | MH | WK15CM | MH | WP20CM |

| K3 | MH | WK15CM | MH | WP20CM | MH | WP35CM |

| N1–N2 | ALP | WN25PM | ALP | WN25PM | ALP | WN25PM |

| N3 | ALP | WN25PM | ALP | WN25PM | ALP | WN25PM |

| S1–S2 | ML | WS30PM | ML | WS30PM | ML | WU35PM |

| S3 | ML | WS30PM | ML | WU35PM | ML | WU35PM |

| S4 | ML | WS30PM | ML | WU35PM | ML | WU35PM |

| H1 | MH | WP25PM | MH | WP20CM | – | – |

Feeds

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ALP | 0,12 | 0,20 | 0,28 | 0,08 | 0,15 | 0,20 | 0,06 | 0,11 | 0,15 | 0,06 | 0,09 | 0,13 | 0,05 | 0,09 | 0,12 | ALP |

| ML | 0,12 | 0,37 | 0,48 | 0,09 | 0,27 | 0,35 | 0,07 | 0,20 | 0,26 | 0,06 | 0,17 | 0,23 | 0,05 | 0,16 | 0,21 | ML |

| MM | 0,28 | 0,70 | 0,81 | 0,21 | 0,50 | 0,58 | 0,15 | 0,38 | 0,44 | 0,13 | 0,33 | 0,38 | 0,12 | 0,30 | 0,35 | MM |

| MH | 0,53 | 0,70 | 1,17 | 0,38 | 0,50 | 0,84 | 0,29 | 0,38 | 0,63 | 0,25 | 0,33 | 0,55 | 0,23 | 0,30 | 0,50 | MH |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ALP | 0,12 | 0,20 | 0,28 | 0,08 | 0,15 | 0,20 | 0,06 | 0,11 | 0,15 | 0,06 | 0,09 | 0,13 | 0,05 | 0,09 | 0,12 | ALP |

| ML | 0,14 | 0,43 | 0,56 | 0,10 | 0,31 | 0,40 | 0,08 | 0,23 | 0,30 | 0,07 | 0,20 | 0,26 | 0,06 | 0,18 | 0,24 | ML |

| MM | 0,33 | 0,81 | 0,94 | 0,24 | 0,58 | 0,67 | 0,18 | 0,43 | 0,50 | 0,16 | 0,38 | 0,44 | 0,14 | 0,35 | 0,40 | MM |

| MH | 0,62 | 0,81 | 1,36 | 0,44 | 0,58 | 0,97 | 0,33 | 0,43 | 0,72 | 0,29 | 0,38 | 0,63 | 0,27 | 0,35 | 0,58 | MH |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ALP | 0,12 | 0,20 | 0,28 | 0,08 | 0,15 | 0,20 | 0,06 | 0,11 | 0,15 | 0,06 | 0,09 | 0,13 | 0,05 | 0,09 | 0,12 | ALP |

| ML | 0,26 | 0,77 | 1,01 | 0,19 | 0,55 | 0,73 | 0,14 | 0,41 | 0,54 | 0,12 | 0,36 | 0,47 | 0,11 | 0,33 | 0,43 | ML |

| MM | 0,59 | 1,46 | 1,70 | 0,43 | 1,04 | 1,21 | 0,32 | 0,78 | 0,90 | 0,28 | 0,68 | 0,79 | 0,25 | 0,62 | 0,72 | MM |

| MH | 1,11 | 1,46 | 2,48 | 0,80 | 1,04 | 1,75 | 0,60 | 0,78 | 1,30 | 0,52 | 0,68 | 1,13 | 0,48 | 0,62 | 1,03 | MH |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 | ||||||||||||

| ALP | 0,12 | 0,20 | 0,28 | 0,08 | 0,15 | 0,20 | 0,06 | 0,11 | 0,15 | 0,06 | 0,09 | 0,13 | 0,05 | 0,09 | 0,12 | ALP |

| ML | 0,19 | 0,56 | 0,73 | 0,14 | 0,40 | 0,53 | 0,10 | 0,30 | 0,40 | 0,09 | 0,26 | 0,34 | 0,08 | 0,24 | 0,32 | ML |

| MM | 0,43 | 1,06 | 1,24 | 0,31 | 0,76 | 0,89 | 0,23 | 0,57 | 0,66 | 0,20 | 0,50 | 0,57 | 0,19 | 0,45 | 0,53 | MM |

| MH | 0,81 | 1,06 | 1,79 | 0,58 | 0,76 | 1,28 | 0,44 | 0,57 | 0,95 | 0,38 | 0,50 | 0,83 | 0,35 | 0,45 | 0,76 | MH |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ALP | .005 | .007 | .009 | .003 | .005 | .007 | .003 | .004 | .005 | .002 | .003 | .004 | .002 | .003 | .004 | ALP |

| ML | .005 | .015 | .019 | .004 | .011 | .014 | .003 | .008 | .010 | .002 | .007 | .009 | .002 | .006 | .008 | ML |

| MM | .011 | .027 | .032 | .008 | .020 | .023 | .006 | .015 | .017 | .005 | .013 | .015 | .005 | .012 | .014 | MM |

| MH | .021 | .027 | .046 | .015 | .020 | .033 | .011 | .015 | .025 | .010 | .013 | .021 | .009 | .012 | .020 | MH |

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ALP | .005 | .007 | .009 | .003 | .005 | .007 | .003 | .004 | .005 | .002 | .003 | .004 | .002 | .003 | .004 | ALP |

| ML | .006 | .017 | .022 | .004 | .012 | .016 | .003 | .009 | .012 | .003 | .008 | .010 | .002 | .007 | .010 | ML |

| MM | .013 | .032 | .037 | .009 | .023 | .026 | .007 | .017 | .020 | .006 | .015 | .017 | .006 | .014 | .016 | MM |

| MH | .024 | .032 | .053 | .018 | .023 | .038 | .013 | .017 | .029 | .011 | .015 | .025 | .010 | .014 | .023 | MH |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ALP | .005 | .007 | .009 | .003 | .005 | .007 | .003 | .004 | .005 | .002 | .003 | .004 | .002 | .003 | .004 | ALP |

| ML | .010 | .030 | .040 | .007 | .022 | .029 | .005 | .016 | .021 | .005 | .014 | .019 | .004 | .013 | .017 | ML |

| MM | .023 | .058 | .067 | .017 | .041 | .047 | .012 | .031 | .035 | .011 | .027 | .031 | .010 | .024 | .028 | MM |

| MH | .044 | .058 | .098 | .031 | .041 | .069 | .023 | .031 | .051 | .020 | .027 | .044 | .019 | .024 | .041 | MH |

| Geometría de plaquita | Avance por diente (fz) programado como % de la profundidad radial de corte (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| ALP | .005 | .007 | .009 | .003 | .005 | .007 | .003 | .004 | .005 | .002 | .003 | .004 | .002 | .003 | .004 | ALP |

| ML | .007 | .022 | .029 | .005 | .016 | .021 | .004 | .012 | .016 | .003 | .010 | .014 | .003 | .010 | .012 | ML |

| MM | .017 | .042 | .048 | .012 | .030 | .035 | .009 | .022 | .026 | .008 | .019 | .022 | .007 | .018 | .021 | MM |

| MH | .032 | .042 | .071 | .023 | .030 | .050 | .017 | .022 | .037 | .015 | .019 | .033 | .014 | .018 | .030 | MH |

Speeds

Velocidades iniciales recomendadas [m/min]

| Grupo de materiales | WK15CM | WK15PM | WN25PM | WP20CM | WP25PM | |||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 660 | 580 | 540 | 395 | 340 | 325 |

| 2 | – | – | – | – | – | – | – | – | – | 410 | 370 | 330 | 330 | 290 | 240 | |

| 3 | – | – | – | – | – | – | – | – | – | 370 | 330 | 305 | 305 | 260 | 210 | |

| 4 | – | – | – | – | – | – | – | – | – | 275 | 260 | 230 | 270 | 220 | 180 | |

| 5 | – | – | – | – | – | – | – | – | – | 330 | 300 | 275 | 220 | 205 | 180 | |

| 6 | – | – | – | – | – | – | – | – | – | 230 | 205 | 175 | 200 | 150 | 120 | |

| M | 1 | – | – | – | – | – | – | – | – | – | 270 | 240 | 210 | 245 | 215 | 200 |

| 2 | – | – | – | – | – | – | – | – | – | 245 | 210 | 190 | 220 | 190 | 155 | |

| 3 | – | – | – | – | – | – | – | – | – | 190 | 175 | 150 | 170 | 145 | 115 | |

| K | 1 | 505 | 460 | 410 | 400 | 290 | 215 | – | – | – | 430 | 390 | 355 | 275 | 245 | 220 |

| 2 | 400 | 355 | 330 | 350 | 235 | 170 | – | – | – | 340 | 305 | 280 | 215 | 190 | 180 | |

| 3 | 335 | 300 | 275 | 280 | 245 | 165 | – | – | – | 290 | 260 | 240 | 180 | 160 | 145 | |

| N | 1 | – | – | – | – | – | – | 1290 | 1135 | 1050 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 1135 | 1050 | 910 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 1135 | 1050 | 910 | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 50 | 30 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 85 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | – | – | – | 170 | 140 | 115 | 145 | 110 | 85 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Grupo de materiales | WP35CM | WP40PM | WS30PM | WS40PM | WU35PM | |||||||||||

| P | 1 | 545 | 475 | 445 | 355 | 310 | 295 | 445 | 385 | 360 | 280 | 245 | 230 | 310 | 275 | 260 |

| 2 | 335 | 305 | 275 | 300 | 260 | 215 | 365 | 325 | 265 | 235 | 205 | 170 | 265 | 230 | 190 | |

| 3 | 305 | 275 | 245 | 275 | 235 | 190 | 340 | 290 | 235 | 215 | 185 | 150 | 240 | 205 | 170 | |

| 4 | 230 | 210 | 190 | 245 | 205 | 160 | 300 | 245 | 200 | 195 | 160 | 130 | 215 | 180 | 145 | |

| 5 | 310 | 275 | 250 | 205 | 185 | 160 | 245 | 230 | 200 | 160 | 140 | 130 | 180 | 160 | 145 | |

| 6 | 190 | 160 | 130 | 180 | 140 | 110 | 220 | 170 | 130 | 140 | 110 | 85 | 155 | 120 | 95 | |

| M | 1 | 245 | 220 | 185 | 235 | 205 | 185 | 270 | 240 | 220 | 260 | 190 | 115 | 205 | 180 | 160 |

| 2 | 220 | 190 | 170 | 210 | 180 | 150 | 245 | 215 | 175 | 230 | 170 | 105 | 185 | 155 | 130 | |

| 3 | 175 | 155 | 140 | 155 | 140 | 110 | 185 | 160 | 125 | 190 | 140 | 80 | 140 | 120 | 95 | |

| K | 1 | 355 | 320 | 290 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 280 | 250 | 230 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | 1075 | 945 | 945 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 945 | 875 | 845 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 875 | 760 | 760 | – | – | – | |

| S | 1 | – | – | – | 50 | 40 | 35 | 55 | 50 | 35 | 62 | 45 | 27 | 40 | 35 | 30 |

| 2 | – | – | – | 50 | 40 | 35 | 55 | 50 | 35 | 55 | 40 | 26 | 40 | 35 | 30 | |

| 3 | – | – | – | 60 | 50 | 35 | 65 | 55 | 35 | 64 | 46 | 29 | 55 | 40 | 30 | |

| 4 | 80 | 60 | 40 | 80 | 60 | 40 | 100 | 70 | 50 | 90 | 66 | 42 | 70 | 55 | 35 | |

| H | 1 | – | – | – | – | – | – | 160 | 120 | 90 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Grupo de materiales | WK15CM | WN25PM | WP20CM | WP25PM | WP35CM | WP40PM | WS30PM | WU35PM | |||||||||||||||||

| P | 1 | – | – | – | – | – | – | 2165 | 1910 | 1770 | 1295 | 1120 | 1060 | 1790 | 1555 | 1460 | 1165 | 1025 | 965 | 1460 | 1260 | 1180 | 1025 | 905 | 845 |

| 2 | – | – | – | – | – | – | 1340 | 1220 | 1080 | 1080 | 940 | 785 | 1105 | 1000 | 905 | 985 | 845 | 710 | 1200 | 1060 | 865 | 865 | 750 | 630 | |

| 3 | – | – | – | – | – | – | 1220 | 1080 | 1000 | 1000 | 845 | 690 | 1000 | 905 | 805 | 905 | 770 | 630 | 1120 | 940 | 770 | 785 | 670 | 550 | |

| 4 | – | – | – | – | – | – | 905 | 845 | 750 | 890 | 725 | 590 | 750 | 690 | 630 | 805 | 670 | 535 | 985 | 805 | 650 | 710 | 590 | 475 | |

| 5 | – | – | – | – | – | – | 1080 | 985 | 905 | 725 | 670 | 590 | 1025 | 905 | 830 | 670 | 610 | 535 | 805 | 750 | 650 | 590 | 535 | 475 | |

| 6 | – | – | – | – | – | – | 750 | 670 | 570 | 650 | 490 | 395 | 630 | 535 | 430 | 590 | 450 | 355 | 725 | 550 | 430 | 510 | 395 | 310 | |

| M | 1 | – | – | – | – | – | – | 890 | 785 | 690 | 805 | 710 | 650 | 805 | 725 | 610 | 770 | 670 | 610 | 890 | 785 | 725 | 670 | 590 | 535 |

| 2 | – | – | – | – | – | – | 805 | 690 | 630 | 725 | 630 | 510 | 725 | 630 | 550 | 690 | 590 | 490 | 805 | 710 | 570 | 610 | 510 | 430 | |

| 3 | – | – | – | – | – | – | 630 | 570 | 490 | 550 | 475 | 370 | 570 | 510 | 450 | 510 | 450 | 355 | 610 | 535 | 415 | 450 | 395 | 310 | |

| K | 1 | 1655 | 1520 | 1340 | – | – | – | 1415 | 1280 | 1165 | 905 | 805 | 725 | 1165 | 1045 | 940 | – | – | – | – | – | – | – | – | – |

| 2 | 1320 | 1165 | 1080 | – | – | – | 1120 | 1000 | 925 | 710 | 630 | 590 | 925 | 830 | 750 | – | – | – | – | – | – | – | – | – | |

| 3 | 1105 | 985 | 905 | – | – | – | 940 | 845 | 785 | 590 | 535 | 475 | 770 | 690 | 630 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | 4230 | 3720 | 3445 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 3720 | 3445 | 2995 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 3720 | 3445 | 2995 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 155 | 140 | 95 | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 140 | 120 | 95 |

| 2 | – | – | – | – | – | – | – | – | – | 155 | 140 | 95 | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 140 | 120 | 95 | |

| 3 | – | – | – | – | – | – | – | – | – | 200 | 155 | 95 | – | – | – | 200 | 155 | 120 | 215 | 180 | 120 | 180 | 140 | 95 | |

| 4 | – | – | – | – | – | – | – | – | – | 275 | 200 | 140 | 260 | 200 | 130 | 260 | 200 | 140 | 335 | 235 | 155 | 235 | 180 | 120 | |

| H | 1 | – | – | – | – | – | – | 550 | 450 | 370 | 475 | 355 | 275 | – | – | – | – | – | – | 535 | 395 | 295 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use