Benvenuto

Conferma le tue preferenze

Aggiorna preferenze

Suggerimenti sui prodotti

Product Family suggestions

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Ciao, User Name

Account selezionato:

C'è un problema con il tuo account. Si prega di contattare l'assistenza clienti.

Sold To Account Modifica account

Ship To Account Modifica account

- Pannello di controllo

- Gestisci ordini

- Gestisci canali

- Rubrica

Notifications

Mark all as read- Modifica password

- Il mio profilo

- Disconnetti

Articolo/i aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Utensili performanti in vendita adesso. Acquistali

WIDIA al tuo servizio

Servizio clienti

Trova i contatti dei centri assistenza clienti in tutto il mondo

Articolo/i aggiunto correttamente al carrello

Visualizza carrello

Visualizza carrello

Modifica della soluzione

Soluzione aggiunta

Nome della soluzione:{{SolutionName}}- Prodotti

- /

- Fresature a candela in metallo duro

- /

- Frese Integrali ad Alte Prestazioni

- /

- VariMill™

- /

- VariMill III™ ER • Series 7V1E 7V2E • Square End • 7 Flute • Inch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

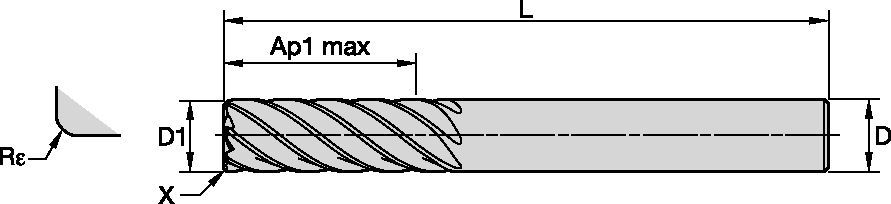

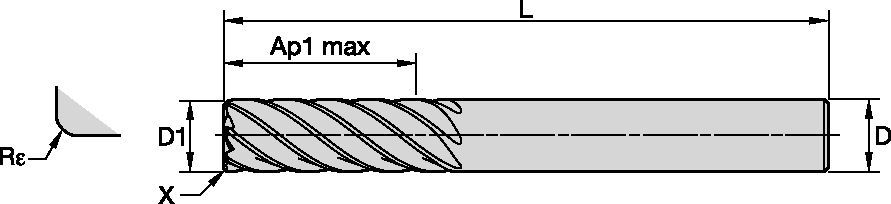

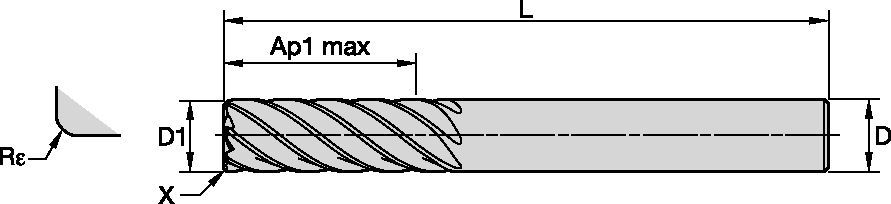

VariMill III™ ER • Series 7V1E 7V2E • Square End • 7 Flute • Inch

VariMill™

Features and benefits

- Unequal flute spacing

- Center cutting

- Ramping angle 3°

- Optimized for difficult-to-machine workpiece materials

- Semi-finishing to finishing applications

- High-speed machining capability

- Standard items listed and additional styles and coatings made-to-order

Uses and application

Trochoidal Milling

Flute Configuration: 7

Fresatura in rampa: Grezzo

Contornatura/fresatura a spallamento: Testa piana

Corner Style: Corner RadiusTipo angolo Raggio di punta

Codolo — Cilindrico liscio

Angolo elica: 38°

Codolo Safe-Lock

Application Data • VariMill III™ ER • Series 7V1E • Semi-Finishing • Inch

| Gruppo materiali |  |  | ||||||||||

| Contornatura (A) | WS15PE | Avanzamento per dente consigliato (IPT = inch/th) per la contornatura (A). | ||||||||||

| A | Velocità di taglio | D1 | ||||||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 4 | Ap1 max | 0.1 x D | 300 | – | 490 | IPT | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 |

| 5 | Ap1 max | 0.1 x D | 200 | – | 330 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| M | 1 | Ap1 max | 0.1 x D | 300 | – | 380 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Ap1 max | 0.1 x D | 200 | – | 260 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| 3 | Ap1 max | 0.1 x D | 200 | – | 230 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

| S | 1 | Ap1 max | 0.1 x D | 160 | – | 300 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Ap1 max | 0.1 x D | 80 | – | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 3 | Ap1 max | 0.1 x D | 80 | – | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 4 | Ap1 max | 0.1 x D | 160 | – | 200 | IPT | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | |

| H | 1 | Ap1 max | 0.1 x D | 260 | – | 460 | IPT | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 |

| 2 | Ap1 max | 0.1 x D | 230 | – | 390 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

Application Data • VariMill III™ ER • Series 7V1E • Finishing • Inch

| Gruppo materiali |  |  | ||||||||||

| Contornatura (A) | WS15PE | Avanzamento per dente consigliato (IPT = inch/th) per la contornatura (A). | ||||||||||

| A | Velocità di taglio | D1 | ||||||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 4 | Ap1 max | 0.06 x D | 590 | - | 980 | IPT | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 |

| 5 | Ap1 max | 0.06 x D | 390 | - | 660 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| M | 1 | Ap1 max | 0.06 x D | 590 | - | 750 | IPT | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 |

| 2 | Ap1 max | 0.06 x D | 390 | - | 520 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 3 | Ap1 max | 0.06 x D | 390 | - | 460 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

| S | 1 | Ap1 max | 0.06 x D | 160 | - | 300 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Ap1 max | 0.06 x D | 80 | - | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 3 | Ap1 max | 0.06 x D | 80 | - | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 4 | Ap1 max | 0.06 x D | 160 | - | 200 | IPT | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0030 | |

| H | 1 | Ap1 max | 0.06 x D | 520 | - | 920 | IPT | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 |

| 2 | Ap1 max | 0.06 x D | 460 | - | 790 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

Application Data • VariMill III™ ER • Series 7V2E • Finishing • Inch

| Gruppo materiali |  |  | ||||||||||

| Contornatura (A) | WS15PE | Avanzamento per dente consigliato (IPT = inch/th) per la contornatura (A). | ||||||||||

| A | Velocità di taglio | D1 | ||||||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | Ap1 max | 0.05 x D | 980 | – | 1310 | IPT | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 |

| 1 | Ap1 max | 0.05 x D | 980 | – | 1310 | IPT | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | |

| 2 | Ap1 max | 0.05 x D | 920 | – | 1250 | IPT | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | |

| 3 | Ap1 max | 0.05 x D | 790 | – | 1050 | IPT | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | |

| 4 | Ap1 max | 0.05 x D | 590 | – | 980 | IPT | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 | |

| 5 | Ap1 max | 0.05 x D | 390 | – | 660 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 6 | Ap1 max | 0.05 x D | 330 | – | 490 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

| M | 1 | Ap1 max | 0.05 x D | 590 | – | 750 | IPT | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 |

| 2 | Ap1 max | 0.05 x D | 390 | – | 520 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 3 | Ap1 max | 0.05 x D | 390 | – | 460 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

| K | 1 | Ap1 max | 0.05 x D | 790 | – | 980 | IPT | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 |

| 2 | Ap1 max | 0.05 x D | 720 | – | 920 | IPT | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | |

| 3 | Ap1 max | 0.05 x D | 720 | – | 850 | IPT | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| S | 1 | Ap1 max | 0.05 x D | 160 | – | 300 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Ap1 max | 0.05 x D | 80 | – | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 3 | Ap1 max | 0.05 x D | 80 | – | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 4 | Ap1 max | 0.05 x D | 160 | – | 200 | IPT | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | |

| H | 1 | Ap1 max | 0.05 x D | 520 | – | 920 | IPT | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 |

| 2 | Ap1 max | 0.06 x D | 460 | – | 790 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |