Product Similar To:

VHSC • XDET-ALP

Inserts • XDET-ALP

Material Number6425775

ISO Catalog IDXDET16M520FRALPANSI Catalog IDXDET16M520FRALP

- K Cast Iron

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6425775 |

| ISO Catalog ID | XDET16M520FRALP |

| ANSI Catalog ID | XDET16M520FRALP |

| Grade | WN10HM |

| Cutting Edges per Insert | 2 |

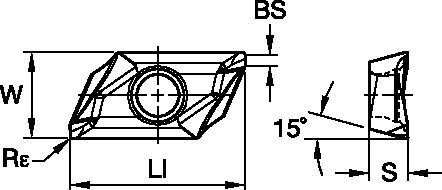

| [LI] Insert Length | 23.02 mm |

| [LI] Insert Length | .906 in |

| [S] Insert Thickness | 5 mm |

| [S] Insert Thickness | .1968 in |

| [W] Insert Width | 11.25 mm |

| [W] Insert Width | .443 in |

| [BS] Corner Facet Length | 0.58 mm |

| [BS] Corner Facet Length | .023 in |

| [Rε] Corner Radius | 2.1 mm |

| [Rε] Corner Radius | .083 in |

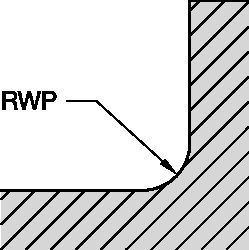

| Resultant WorkPiece Radius | 2 mm |

| Resultant WorkPiece Radius | .079 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | .0008 in |

Workpiece Materials

- Cast Iron

- Non-Ferrous

Features and benefits

- Super-positive ALP insert geometry.

- Polished rake face to reduce build up edge.

- Sharp edge preparation "FRALP" for roughing and finishing applications.

- Honed edge preparation "ERALP" for heavy roughing applications.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | 0,12 | 0,45 | 0,81 | 0,08 | 0,33 | 0,58 | 0,06 | 0,25 | 0,43 | 0,06 | 0,21 | 0,38 | 0,05 | 0,20 | 0,35 | .F..ALP |

| .E..ALP | 0,15 | 0,50 | 0,92 | 0,11 | 0,36 | 0,66 | 0,08 | 0,27 | 0,50 | 0,07 | 0,24 | 0,43 | 0,07 | 0,22 | 0,40 | .E..ALP |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | .005 | .018 | .032 | .003 | .013 | .023 | .003 | .010 | .017 | .002 | .009 | .015 | .002 | .008 | .014 | .F..ALP |

| .E..ALP | .006 | .020 | .037 | .004 | .014 | .027 | .003 | .011 | .020 | .003 | .009 | .017 | .003 | .009 | .016 | .E..ALP |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds For Wet Machining [m/min]

| Material Group | WN10HM | |||

| N | 1 | 2950 | 1800 | 875 |

| 2 | 2950 | 1800 | 875 | |

| 3 | 1600 | 850 | 480 | |

Recommended Starting Speeds for Wet Machining [SFM]

| Material Group | WN10HM | |||

| N | 1 | 9640 | 5880 | 2860 |

| 2 | 9640 | 5880 | 2860 | |

| 3 | 5230 | 2775 | 1565 | |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| N1–N2 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

| N3 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

I have read and accepted the Terms & Conditions of use