Produit similaire à:

VXF™-12 • Shell Mills • Inch

Shell Mills • Inch

Numéro de matériel6596763

Ref. ISO CatalogueVXF150Z04S075XD12Ref. ANSI CatalogueVXF150Z04S075XD12

- P Acier

- M Acier inoxydable

- K Fonte

- N Non ferreux

- S Alliages hautes températures

- H Matériaux trempés

100018357

Spiral Circular

Fraisage hélicoïdal

Ramping : Ébauche

Counter Boring

38295

Usinage de poches

Fraisage en plongée

Inclined Square End Mill

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Aperçu

- Données d'application

- Téléchargements

- Pièces compatibles côté machine

- Pièces compatibles côté pièce

- Pièces de rechange

- Révision

- FAQ

| Numéro de matériel | 6596763 |

| Ref. ISO Catalogue | VXF150Z04S075XD12 |

| Ref. ANSI Catalogue | VXF150Z04S075XD12 |

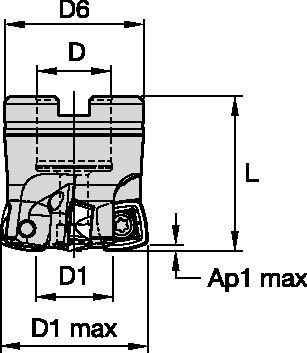

| [D1MAX] Diamètre de coupe maximal | 38.1 mm |

| [D1MAX] Diamètre de coupe maximal | 1.5 in |

| [D1] Diamètre effectif de coupe | 19.946 mm |

| [D1] Diamètre effectif de coupe | .7853 in |

| [D] Adaptateur / Queue / Diamètre d’alésage | 19.05 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | .75 in |

| [D6] Diamètre du moyeu | 36 mm |

| [D6] Diamètre du moyeu | 1.417 in |

| [L] Longueur totale | 40 mm |

| [L] Longueur totale | 1.574 in |

| [AP1MAX] 1re profondeur de coupe maximale | 2.5 mm |

| [AP1MAX] 1re profondeur de coupe maximale | .0984 in |

| Nombre de plaquettes | 4 |

| Angle de ramping maximum | 0.95 |

| T/Min max | 27500 |

| Alimentation en arrosage | Y |

| Poids Livres | 0.38 |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Non ferreux

- Alliages hautes températures

- Matériaux trempés

Uses and application

100018357

Spiral Circular

Fraisage hélicoïdal

Ramping : Ébauche

Counter Boring

38295

Usinage de poches

Fraisage en plongée

Inclined Square End Mill

Features and benefits

- 16.5° lead angle redistributes cutting forces in the spindle z-axis direction.

- Greatly reduces tool defl ection and vibrations for improved tool life.

- Suitable for long tool reach.

- Unique integrated radial wiping facet to achieve a nice wall finish at pocket and helical interpolation milling.

- Durable cutting edges qualifi ed to machine a wide range of materials.

- WS40PM — best-in-class milling grade for machining stainless steel and HTA.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Guide de sélection des plaquettes

| Light | General | Heavy | ||||

| Material | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | XDPT-MM | WP25PM | XDPT-MM | WS40PM | XDPT-MH | WP40PM |

| P3–P4 | XDPT-MM | WP25PM | XDPT-MM | WS40PM | XDPT-MH | WP40PM |

| P5–P6 | XDPT-MM | WP25PM | XDPT-MM | WS40PM | XDPT-MH | WP40PM |

| M1–M2 | XDPT-MM | WS40PM | XDPT-MM | WS40PM | XDPT-MH | WP40PM |

| M3 | XDPT-MM | WS40PM | XDPT-MM | WS40PM | XDPT-MH | WP40PM |

| S1–S2 | XDPT-MM | WP25PM | XDPT-MM | WS40PM | XDPT-MH | WP40PM |

| S3 | XDPT-MM | WS40PM | XDPT-MM | WS40PM | XDPT-MH | WP40PM |

| S4 | XDPT-MM | WS40PM | XDPT-MM | WS40PM | XDPT-MH | WP40PM |

Feeds

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40–100 % | ||||||||||||

| .E..MM | 0,43 | 1,39 | 2,20 | 0,31 | 0,99 | 1,56 | 0,23 | 0,74 | 1,15 | 0,20 | 0,64 | 1,00 | 0,19 | 0,59 | 0,92 | .E..MM |

| .S..MH | 0,62 | 1,57 | 2,41 | 0,45 | 1,12 | 1,70 | 0,33 | 0,84 | 1,26 | 0,29 | 0,73 | 1,10 | 0,27 | 0,67 | 1,00 | .S..MH |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40–100 % | ||||||||||||

| .E..MM | 0,49 | 1,59 | 2,52 | 0,35 | 1,13 | 1,78 | 0,26 | 0,84 | 1,31 | 0,23 | 0,73 | 1,14 | 0,21 | 0,67 | 1,04 | .E..MM |

| .S..MH | 0,70 | 1,80 | 2,76 | 0,51 | 1,28 | 1,94 | 0,38 | 0,95 | 1,44 | 0,33 | 0,83 | 1,25 | 0,30 | 0,76 | 1,14 | .S..MH |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40–100 % | ||||||||||||

| .E..MM | 0,36 | 1,15 | 1,81 | 0,26 | 0,83 | 1,29 | 0,19 | 0,62 | 0,96 | 0,17 | 0,54 | 0,83 | 0,15 | 0,49 | 0,76 | .E..MM |

| .S..MH | 0,51 | 1,30 | 1,99 | 0,37 | 0,93 | 1,41 | 0,28 | 0,70 | 1,05 | 0,24 | 0,61 | 0,91 | 0,22 | 0,55 | 0,83 | .S..MH |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..MM | .018 | .051 | .094 | .013 | .035 | .059 | .009 | .025 | .042 | .008 | .022 | .037 | .007 | .020 | .033 | .E..MM |

| .S..MH | .032 | .070 | .118 | .023 | .046 | .071 | .017 | .033 | .050 | .014 | .029 | .043 | .013 | .026 | .039 | .S..MH |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..MM | .020 | .058 | .109 | .014 | .039 | .067 | .010 | .028 | .047 | .009 | .025 | .041 | .008 | .022 | .037 | .E..MM |

| .S..MH | .036 | .080 | .141 | .025 | .052 | .080 | .019 | .037 | .056 | .016 | .032 | .048 | .015 | .029 | .043 | .S..MH |

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..MM | .015 | .043 | .076 | .011 | .029 | .050 | .008 | .022 | .036 | .007 | .019 | .031 | .006 | .017 | .028 | .E..MM |

| .S..MH | .027 | .058 | .093 | .019 | .039 | .059 | .014 | .028 | .042 | .012 | .024 | .036 | .011 | .022 | .033 | .S..MH |

Speeds

Vitesses de départ recommandées [m/mn]*

| Material Group | WP25PM | WP40PM | WS40PM | |||||||

| P | 1 | 395 | 340 | 325 | 355 | 310 | 295 | – | – | – |

| 2 | 330 | 290 | 240 | 300 | 260 | 215 | – | – | – | |

| 3 | 305 | 260 | 210 | 275 | 235 | 190 | – | – | – | |

| 4 | 270 | 220 | 180 | 245 | 205 | 160 | – | – | – | |

| 5 | 220 | 205 | 180 | 205 | 185 | 160 | 205 | 175 | 145 | |

| 6 | 200 | 150 | 120 | 180 | 140 | 110 | 180 | 130 | 95 | |

| M | 1 | 245 | 215 | 200 | 235 | 205 | 185 | 250 | 205 | 170 |

| 2 | 220 | 190 | 155 | 210 | 180 | 150 | 215 | 175 | 145 | |

| 3 | 170 | 145 | 115 | 155 | 140 | 110 | 175 | 130 | 100 | |

| S | 1 | 50 | 40 | 30 | 50 | 40 | 35 | 50 | 40 | 30 |

| 2 | 50 | 40 | 30 | 50 | 40 | 35 | 50 | 40 | 30 | |

| 3 | 60 | 50 | 30 | 60 | 50 | 35 | 60 | 50 | 30 | |

| 4 | 85 | 60 | 40 | 80 | 60 | 40 | 70 | 60 | 35 | |

Recommended Starting Speeds [SFM]*

| Material Group | WP25PM | WP40PM | WS40PM | |||||||

| P | 1 | 1295 | 1115 | 1065 | 1165 | 1015 | 970 | – | – | – |

| 2 | 1085 | 950 | 785 | 985 | 855 | 705 | – | – | – | |

| 3 | 1000 | 855 | 690 | 900 | 770 | 625 | – | – | – | |

| 4 | 885 | 720 | 590 | 805 | 675 | 525 | – | – | – | |

| 5 | 720 | 675 | 590 | 675 | 605 | 525 | 675 | 575 | 475 | |

| 6 | 655 | 490 | 395 | 590 | 460 | 360 | 590 | 425 | 310 | |

| M | 1 | 805 | 705 | 655 | 770 | 675 | 605 | 820 | 675 | 560 |

| 2 | 720 | 625 | 510 | 690 | 590 | 490 | 705 | 575 | 475 | |

| 3 | 560 | 475 | 375 | 510 | 460 | 360 | 575 | 425 | 330 | |

| S | 1 | 165 | 130 | 100 | 165 | 130 | 115 | 165 | 130 | 100 |

| 2 | 165 | 130 | 100 | 165 | 130 | 115 | 165 | 130 | 100 | |

| 3 | 195 | 165 | 100 | 195 | 165 | 115 | 195 | 165 | 100 | |

| 4 | 280 | 195 | 130 | 260 | 195 | 130 | 230 | 195 | 115 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use