Produkt ähnlich wie:

Top Cut 4 • Umfangswendeschneidplatten • Schruppen V36

TC4 • Außen Wendeschneidplatten • V36

Material Nummer5542622

ISO Katalog NummerTCF050204BPV36ANSI Katalog NummerTCF050204BPV36

- P Stahl

- M Rostfreier Stahl

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 5542622 |

| ISO Katalog Nummer | TCF050204BPV36 |

| ANSI Katalog Nummer | TCF050204BPV36 |

| Sorte | WU40PH |

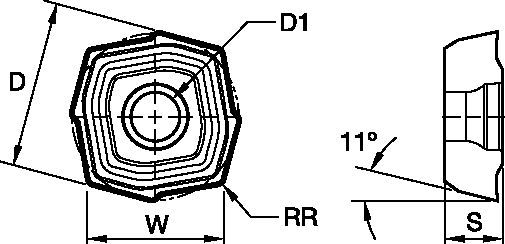

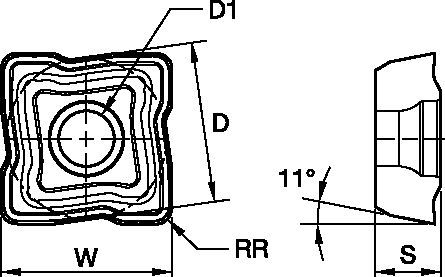

| [D] Wendeschneidplatten-Größe (Inkreis) | 5.07 mm |

| [D] Wendeschneidplatten-Größe (Inkreis) | 0.2 in |

| [D1] Wendeschneidplatte Bohrungsgröße | 2.4 mm |

| [D1] Wendeschneidplatte Bohrungsgröße | 0.094 in |

| [W] Schnittbreite | 5.4 mm |

| [W] Schnittbreite | 0.213 in |

| [S] Dicke der Wendeschneidplatte | 2.4 mm |

| [S] Dicke der Wendeschneidplatte | 0.094 in |

| [RR] Eckenradius | 0.4 mm |

| [RR] Eckenradius | 0.015 in |

| Wende-schneid-platten-Größe | B |

Werkstoffe

- Stahl

- Rostfreier Stahl

Grades

WU40PH

Zusammensetzung: Mit einer Mehrlagen-PVD TiN-TiAlN-Beschichtung und einem zähen Substratwidersteht diese Sorte Bearbeitungen mit unterbrochenen Schnitten und sorgt mit ihrer hohen Verschleißfestigkeit für lange Standzeiten.

Anwendung: Aufgrund der hohen Zuverlässigkeit die erste Wahl für die Bearbeitung der meisten Werkstoffe. Diese Sorte sollte wegender schärferen Schneidkanten mit mittleren Schnittgeschwindigkeiten und hohen Vorschüben sowie für Anwendungen verwendet werden, bei denen eine hoheZähigkeit gefordert wird. Sie eignet sich für Werkstoffe wie Stahl, nichtrostenden Stahl und Gusseisenund unter bestimmten Bedingungen auch für hochtemperaturbeständige Legierungen.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Insert Selection

TC4 • Auswahlhilfe für Wendeschneidplatten

| Werkstoffgruppe | Geometrie | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| Wende- schneidplatte Außen | Wende- schneidplatte Innen | Wende- schneidplatte Außen | Wende- schneidplatte Innen | Wende- schneidplatte Außen | Wende- schneidplatte Innen | ||

| P1 | V38/DU | WU25CH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| P2–P4 | V34/DU | WPK10CH | WU40PH/WU20PH | WU25CH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| P5–P6 | V36/DU | WU25CH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| M1–M3 | V36/DU | WU25CH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| K1–K3 | V34/DU | WPK10CH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

| N1–N4 | V36 | WN10PH | WN10PH | WN10PH | WN10PH | WN10PH | WN10PH |

| S1–S4 | V38/DU | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH | WU40PH/WU20PH |

Anwendungsdaten

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | |||||||

| innen | außen | Min. | Startwert | Max. | |||||||

| –V38 | 0,06–0,08 | 0,08–0,11 | 0,10–0,13 | 0,11–0,14 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 200 | mm/U | – | – | 0,07–0,10 | 0,08–0,10 | |

| –V38 | 0,06–0,10 | 0,08–0,13 | 0,10–0,15 | 0,11–0,16 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 200 | mm/U | – | – | 0,07–0,11 | 0,08–0,11 | |

| –V34 | 0,06–0,10 | 0,08–0,15 | 0,10–0,16 | 0,11–0,17 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/U | – | – | 0,07–0,12 | 0,08–0,13 | |

| –V34 | 0,08–0,15 | 0,10–0,16 | 0,11–0,18 | 0,12–0,20 | |||||||

| –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/U | – | – | 0,08–0,13 | 0,09–0,15 | |

| –V34 | 0,08–0,15 | 0,10–0,16 | 0,11–0,18 | 0,12–0,20 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/U | – | – | 0,08–0,13 | 0,09–0,15 | |

| –V36 | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/U | – | – | 0,07–0,11 | 0,08–0,12 | |

| 0,06-0,10 | 0,08-0,14 | 0,10-0,15 | 0,11-0,16 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 130 | 165 | mm/U | – | – | 0,07-0,11 | 0,08-0,12 | |

| 0,06-0,11 | 0,07-0,11 | 0,08-0,12 | 0,10-0,14 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 130 | 190 | mm/U | – | – | 0,06-0,09 | 0,07-0,10 | |

| –V38 | 0,06–0,10 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 | |||||||

| –DU | WU20PH | WU20PH | 110 | 140 | 190 | mm/U | – | – | 0,06–0,09 | 0,07–0,10 | |

| 0,06-0,10 | 0,07-0,11 | 0,08-0,12 | 0,10-0,14 | ||||||||

| –DU | WU20PH | WU20PH | 80 | 100 | 160 | mm/U | – | – | 0,06-0,09 | 0,07-0,10 | |

| 0,08-0,14 | 0,08-0,16 | 0,10-0,18 | 0,12-0,24 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/U | – | – | 0,07-0,13 | 0,09-0,18 | |

| –V34 | 0,08–0,14 | 0,08–0,16 | 0,10–0,18 | 0,12–0,24 | |||||||

| –DU | WU20PH | WU20PH | 80 | 140 | 200 | mm/U | – | – | 0,07–0,13 | 0,09–0,18 | |

| 0,08-0,14 | 0,08-0,16 | 0,10-0,18 | 0,12-0,24 | ||||||||

| –DU | WU20PH | WU20PH | 80 | 140 | 190 | mm/U | – | – | 0,07-0,13 | 0,09-0,18 | |

| 0,06-0,10 | 0,08-0,14 | 0,10-0,15 | 0,11-0,16 | ||||||||

| –V36 | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | |||||||

| 0,06-0,10 | 0,07-0,11 | 0,08-0,12 | 0,10-0,14 | ||||||||

| 0,08-0,12 | 0,08-0,13 | 0,10-0,15 | 0,12-0,19 | ||||||||

| –DU | WU20PH | WU20PH | 20 | 30 | 40 | mm/U | – | – | 0,07-0,11 | 0,09-0,14 | |

| –V38 | 0,08–0,12 | 0,08–0,13 | 0,10–0,15 | 0,12–0,19 | |||||||

| –DU | WU20PH | WU20PH | 30 | 40 | 60 | mm/U | – | – | 0,07–0,11 | 0,09–0,14 | |

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | |||||||

| innen | außen | Min. | Startwert | Max. | |||||||

| –V38 | 0,13–0,16 | 0,15–0,18 | 0,16–0,23 | 0,17–0,24 | |||||||

| –DU | WU20PH | WU20PH | 90 | 140 | 200 | mm/U | 0,09–0,12 | 0,11–0,13 | – | – | |

| –V38 | 0,13–0,17 | 0,15–0,19 | 0,16–0,24 | 0,17–0,25 | |||||||

| –DU | WU20PH | WU20PH | 90 | 140 | 200 | mm/U | 0,09–0,13 | 0,11–0,14 | – | – | |

| –V34 | 0,13–0,20 | 0,15–0,21 | 0,16–0,28 | 0,17–0,30 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/U | 0,09–0,15 | 0,11–0,15 | – | – | |

| –V34 | 0,16–0,24 | 0,16–0,24 | 0,18–0,30 | 0,19–0,32 | |||||||

| –DU | WU20PH | WU20PH | 90 | 160 | 250 | mm/U | 0,12–0,16 | 0,12–0,18 | – | – | |

| –V34 | 0,14–0,22 | 0,16–0,24 | 0,18–0,30 | 0,19–0,32 | |||||||

| –DU | WU20PH | WU20PH | 90 | 150 | 250 | mm/U | 0,12–0,16 | 0,12–0,18 | – | – | |

| –V36 | 0,13–0,18 | 0,15–0,20 | 0,16–0,28 | 0,17–0,30 | |||||||

| –DU | WU20PH | WU20PH | 90 | 140 | 200 | mm/U | 0,09–0,13 | 0,11–0,15 | – | – | |

| 0,13-0,18 | 0,15–0,20 | 0,16-0,28 | 0,17–0,29 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 120 | 160 | mm/U | 0,09-0,13 | 0,11-0,15 | – | – | |

| 0,12-0,17 | 0,14-0,21 | 0,16-0,23 | 0,16-0,24 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 120 | 190 | mm/U | 0,09-0,13 | 0,10-0,15 | – | – | |

| –V38 | 0,12–0,17 | 0,14–0,21 | 0,16–0,23 | 0,16–0,24 | |||||||

| –DU | WU20PH | WU20PH | 90 | 110 | 160 | mm/U | 0,09–0,13 | 0,10–0,15 | – | – | |

| 0,12-0,17 | 0,14-0,21 | 0,16-0,23 | 0,16-0,24 | ||||||||

| –DU | WU20PH | WU20PH | 80 | 90 | 160 | mm/U | 0,09-0,13 | 0,10-0,15 | – | – | |

| 0,14-0,26 | 0,16-0,30 | 0,18-0,32 | 0,20-0,36 | ||||||||

| –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/U | 0,10-0,19 | 0,12-0,22 | – | – | |

| –V34 | 0,14–0,26 | 0,16–0,30 | 0,18–0,32 | 0,20–0,36 | |||||||

| –DU | WU20PH | WU20PH | 80 | 140 | 200 | mm/U | 0,10–0,19 | 0,12–0,22 | – | – | |

| 0,14-0,26 | 0,16-0,30 | 0,18-0,32 | 0,20-0,36 | ||||||||

| –DU | WU20PH | WU20PH | 80 | 130 | 190 | mm/U | 0,10-0,19 | 0,12-0,22 | – | – | |

| 0,13-0,18 | 0,15–0,20 | 0,16-0,28 | 0,17-0,30 | ||||||||

| –V36 | 0,13–0,18 | 0,15–0,20 | 0,16–0,28 | 0,17–0,30 | |||||||

| 0,12-0,17 | 0,14-0,21 | 0,16-0,23 | 0,16-0,24 | ||||||||

| 0,14-0,21 | 0,16-0,24 | 0,18-0,26 | 0,20-0,30 | ||||||||

| –DU | WU20PH | WU20PH | 20 | 25 | 40 | mm/U | 0,10-0,15 | 0,12-0,18 | – | – | |

| –V38 | 0,14–0,21 | 0,16–0,24 | 0,18–0,26 | 0,20–0,30 | |||||||

| –DU | WU20PH | WU20PH | 30 | 35 | 50 | mm/U | 0,10–0,15 | 0,12–0,18 | – | – | |

| Avanzamento al giro consigliato | |||||||||||

| Sorte | Schnittgeschwindigkeit | ||||||||||

| Werkstoffgruppe | Geometrie | innen | außen | Min. | Startwert | Max. | Werkzeugdurchmesser | 12,00 | 14,00 | 19,00 | 24,00 |

| P0 | –V38 | WU40PH | WU25CH | 120 | 180 | 260 | mm/rev | 0,06–0,08 | 0,08–0,11 | 0,10–0,13 | 0,11–0,14 |

| P0 | –DU | WU20PH | WU20PH | 90 | 150 | 200 | mm/rev | – | – | 0.07–0.10 | 0.08–0.10 |

| P1 | –V38 | WU40PH | WU25CH | 120 | 180 | 260 | mm/rev | 0,06–0,10 | 0,08–0,13 | 0,10–0,15 | 0,11–0,16 |

| P1 | –DU | WU20PH | WU20PH | 90 | 150 | 200 | mm/rev | – | – | 0.07–0.11 | 0.08–0.11 |

| P2 | –V34 | WU40PH | WU25CH | 120 | 190 | 280 | mm/rev | 0,06–0,10 | 0,08–0,15 | 0,10–0,16 | 0,11–0,17 |

| P2 | –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/rev | – | – | 0.07–0.12 | 0.08–0.13 |

| P3 | –V34 | WU40PH | WPK10CH | 120 | 200 | 310 | mm/rev | 0,08–0,15 | 0,10–0,16 | 0,11–0,18 | 0,12–0,20 |

| P3 | –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/rev | – | – | 0.08–0.13 | 0.09–0.15 |

| P4 | –V34 | WU40PH | WPK10CH | 120 | 190 | 310 | mm/rev | 0,08–0,15 | 0,10–0,16 | 0,11–0,18 | 0,12–0,20 |

| P4 | –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/rev | – | – | 0.08–0.13 | 0.09–0.15 |

| P5 | –V36 | WU40PH | WU25CH | 120 | 180 | 250 | mm/rev | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 |

| P5 | –DU | WU20PH | WU20PH | 90 | 150 | 220 | mm/rev | – | – | 0.07–0.11 | 0.08–0.12 |

| P6 | -V36 | WU40PH | WU25CH | 120 | 160 | 210 | mm/rev | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 |

| P6 | –DU | WU20PH | WU20PH | 90 | 130 | 165 | mm/rev | – | – | 0.07–0.11 | 0.08–0.12 |

| M1 | -V38 | WU40PH | WU40PH | 120 | 160 | 240 | mm/rev | 0,06–0,11 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 |

| M1 | –DU | WU20PH | WU20PH | 90 | 130 | 190 | mm/rev | – | – | 0.06–0.09 | 0.07–0.10 |

| M2 | –V38 | WU40PH | WU40PH | 110 | 140 | 210 | mm/rev | 0,06–0,10 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 |

| M2 | –DU | WU20PH | WU20PH | 110 | 140 | 190 | mm/rev | – | – | 0.06–0.09 | 0.07–0.10 |

| M3 | -V36 | WU40PH | WU40PH | 100 | 120 | 200 | mm/rev | 0,06–0,10 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 |

| M3 | –DU | WU20PH | WU20PH | 80 | 100 | 160 | mm/rev | – | – | 0.06–0.09 | 0.07–0.10 |

| K1 | -V34 | WU25CH | WPK10CH | 120 | 200 | 280 | mm/rev | 0,08–0,14 | 0,08–0,16 | 0,10–0,18 | 0,12–0,24 |

| K1 | –DU | WU20PH | WU20PH | 90 | 160 | 220 | mm/rev | – | – | 0.07–0.13 | 0.09–0.18 |

| K2 | –V34 | WU40PH | WPK10CH | 100 | 180 | 260 | mm/rev | 0,08–0,14 | 0,08–0,16 | 0,10–0,18 | 0,12–0,24 |

| K2 | –DU | WU20PH | WU20PH | 80 | 140 | 200 | mm/rev | – | – | 0.07–0.13 | 0.09–0.18 |

| K3 | -V34 | WU40PH | WPK10CH | 100 | 170 | 240 | mm/rev | 0,08–0,14 | 0,08–0,16 | 0,10–0,18 | 0,12–0,24 |

| K3 | –DU | WU20PH | WU20PH | 80 | 140 | 190 | mm/rev | – | – | 0.07–0.13 | 0.09–0.18 |

| N1 | -V36 | WN10PH | WN10PH | 250 | 350 | 500 | mm/rev | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 |

| N2 | –V36 | WN10PH | WN10PH | 150 | 300 | 450 | mm/rev | 0,06–0,10 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 |

| N3 | -V36 | WN10PH | WN10PH | 80 | 120 | 150 | mm/rev | 0,06–0,10 | 0,07–0,11 | 0,08–0,12 | 0,10–0,14 |

| S3 | -V38 | WU40PH | WU40PH | 20 | 30 | 45 | mm/rev | 0,08–0,12 | 0,08–0,13 | 0,10–0,15 | 0,12–0,19 |

| S3 | –DU | WU20PH | WU20PH | 20 | 30 | 40 | mm/rev | – | – | 0.07–0.11 | 0.09–0.14 |

| S4 | –V38 | WU40PH | WU40PH | 35 | 40 | 65 | mm/rev | 0,08–0,12 | 0,08–0,13 | 0,10 –0,15 | 0,12–0,19 |

| S4 | –DU | WU20PH | WU20PH | 30 | 40 | 60 | mm/rev | – | – | 0.07–0.11 | 0.09–0.14 |

| Wendeschneidplatten-Größe | Durchmesser- bereich mm (in) | 2 x D/3 x D | 4 x D | 5 x D | ||||||

| X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | ||

| A | 12,00 | 0,5 | D1 + 1 mm | +/-0,20 | 0,5 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| B | 14,00 | 0,5 | D1 + 1 mm | +/-0,20 | 0,5 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| C | 19,00 | 0,5 | D1 + 1 mm | +/-0,20 | 0,5 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| D | 24,00 | 0,8 | D1 + 1,6 mm | +/-0,20 | 0,8 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| E | 30,00 | 0,8 | D1 + 1,6 mm | +/-0,20 | 0,8 | D1 + 1 mm | +/-0,35 | +/-0,35 | ||

| F | 37,00 | 0,8 | D1 + 1,6 mm | +/-0,25 | 0,8 | D1 + 1 mm | +/-0,38 | +/-0,38 | ||

| G | 46,00 | 1 | D1 + 2 mm | +/-0,25 | 0,8 | D1 + 1 mm | +/-0,38 | +/-0,38 | ||

| H | 57,00 | 1 | D1 + 2 mm | +/-0,28 | 0,8 | D1 + 1 mm | +/-0,42 | +/-0,42 | ||

| Wendeschneidplatten-Größe | Durchmesserbereich (mm) | 2 x D und 3 x D | 4 x D | 5 x D | |||

| X-Versatzwert | D1 max. | X-Versatzwert | D1 max. | X-Versatz | D1 max. | ||

| A | 12,00 | 0,5 | D1 + 1mm | 0,5 | D1 + 1mm | ||

| B | 14,00 | 0,5 | D1 + 1mm | 0,5 | D1 + 1mm | ||

| C | 19,00 | 0,5 | D1 + 1mm | 0,5 | D1 + 1mm | ||

| D | 24,00 | 0,8 | D1 + 1,6mm | 0,8 | D1 + 1mm | ||

| E | 30,00 | 0,8 | D1 + 1,6mm | 0,8 | D1 + 1mm | ||

| F | 37,00 | 0,8 | D1 + 1,6mm | 0,8 | D1 + 1mm | ||

| G | 46,00 | 1 | D1 + 2mm | 0,8 | D1 + 1mm | ||

| H | 57,00 | 1 | D1 + 2mm | 0,8 | D1 + 1mm | ||

| Wendeschneidplatten-Größe | Durchmesser- bereich mm (in) | 2 x D/3 x D | 4 x D | 5 x D | |||||

| D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | X-Offset- wert max. in mm (max. in Zoll) | D1 max. Wert mm (in) | Bohrungs- toleranz mm (in) | ||

| A | 12,00 | D1 + 1mm | +/- 0,20 | 0,5 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| B | 14,00 | D1 + 1mm | +/- 0,20 | 0,5 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| C | 19,00 | D1 + 1mm | +/- 0,20 | 0,5 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| D | 24,00 | D1 + 1,6mm | +/- 0,20 | 0,8 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| E | 30,00 | D1 + 1,6mm | +/- 0,20 | 0,8 | D1 + 1mm | +/- 0,35 | +/- 0,35 | ||

| F | 37,00 | D1 + 1,6mm | +/- 0,25 | 0,8 | D1 + 1mm | +/- 0,38 | +/- 0,38 | ||

| G | 46,00 | D1 + 2mm | +/- 0,25 | 0,8 | D1 + 1mm | +/- 0,38 | +/- 0,38 | ||

| H | 57,00 | D1 + 2mm | +/- 0,28 | 0,8 | D1 + 1mm | +/- 0,42 | +/- 0,42 | ||

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | 1,188 | 1,469 | 1,813 | 2,250 | |||

| innen | außen | Min. | Startwert | Max. | |||||||

| P0 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| P1 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| P2 | –V34 | WU40PH | WU25CH | 360 | 570 | 840 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| P3 | –V34 | WU40PH | WPK10CH | 360 | 600 | 930 | IPR | 0.0053 | 0.0063 | 0.0071 | 0.0075 |

| P4 | –V34 | WU40PH | WPK10CH | 360 | 570 | 930 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0075 |

| P5 | –V36 | WU40PH | WU25CH | 360 | 540 | 750 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| P6 | -V36 | WU40PH | WU25CH | 360 | 480 | 630 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| M1 | -V38 | WU40PH | WU40PH | 360 | 480 | 720 | IPR | 0.0047 | 0.0055 | 0.0063 | 0.0063 |

| M2 | –V38 | WU40PH | WU40PH | 330 | 420 | 630 | IPR | 0.0047 | 0.0055 | 0.0063 | 0.0063 |

| M3 | -V36 | WU40PH | WU40PH | 300 | 360 | 600 | IPR | 0.0047 | 0.0055 | 0.0063 | 0.0063 |

| K1 | -V34 | WU25CH | WPK10CH | 360 | 600 | 840 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| K2 | –V34 | WU40PH | WPK10CH | 300 | 540 | 780 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| K3 | -V34 | WU40PH | WPK10CH | 300 | 510 | 720 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| N1 | -V36 | WN10PH | WN10PH | 750 | 1050 | 1500 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| N2 | –V36 | WN10PH | WN10PH | 450 | 900 | 1350 | IPR | 0.0051 | 0.0059 | 0.0063 | 0.0067 |

| N3 | -V36 | WN10PH | WN10PH | 240 | 360 | 450 | IPR | 0.0047 | 0.0055 | 0.0063 | 0.0063 |

| S3 | -V38 | WU40PH | WU40PH | 60 | 90 | 135 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| S4 | –V38 | WU40PH | WU40PH | 105 | 120 | 195 | IPR | 0.0055 | 0.0063 | 0.0071 | 0.0079 |

| Empfohlener Vorschub pro Umdrehung | |||||||||||

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | 0,473 | 0,563 | 0,750 | 0,969 | |||

| innen | außen | Min. | Startwert | Max. | |||||||

| P0 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0024 | 0.0031 | 0,0039 | 0.0043 |

| P1 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| P2 | –V34 | WU40PH | WU25CH | 360 | 570 | 840 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| P3 | –V34 | WU40PH | WPK10CH | 360 | 600 | 930 | IPR | 0.0031 | 0.0039 | 0.0043 | 0.0047 |

| P4 | –V34 | WU40PH | WPK10CH | 360 | 570 | 930 | IPR | 0.0031 | 0.0039 | 0.0043 | 0.0047 |

| P5 | –V36 | WU40PH | WU25CH | 360 | 540 | 750 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| P6 | -V36 | WU40PH | WU25CH | 360 | 480 | 630 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| M1 | -V38 | WU40PH | WU40PH | 360 | 480 | 720 | IPR | 0.0024 | 0.0028 | 0.0031 | 0.0039 |

| M2 | –V38 | WU40PH | WU40PH | 330 | 420 | 630 | IPR | 0.0024 | 0.0028 | 0.0031 | 0.0039 |

| M3 | -V36 | WU40PH | WU40PH | 300 | 360 | 600 | IPR | 0.0024 | 0.0028 | 0.0031 | 0.0039 |

| K1 | -V34 | WU25CH | WPK10CH | 360 | 600 | 840 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| K2 | –V34 | WU40PH | WPK10CH | 300 | 540 | 780 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| K3 | -V34 | WU40PH | WPK10CH | 300 | 510 | 720 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| N1 | -V36 | WN10PH | WN10PH | 750 | 1050 | 1500 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| N2 | –V36 | WN10PH | WN10PH | 450 | 900 | 1350 | IPR | 0.0024 | 0.0031 | 0.0039 | 0.0043 |

| N3 | -V36 | WN10PH | WN10PH | 240 | 360 | 450 | IPR | 0.0024 | 0.0028 | 0.0031 | 0.0039 |

| S3 | -V38 | WU40PH | WU40PH | 60 | 90 | 135 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| S4 | –V38 | WU40PH | WU40PH | 105 | 120 | 195 | IPR | 0.0031 | 0.0031 | 0.0039 | 0.0047 |

| Recommended Feed Rate per Revolution | |||||||||||

| Werkstoffgruppe | Geometrie | Sorte | Schnittgeschwindigkeit | Werkzeugdurchmesser | .473 | .563 | .750 | .969 | |||

| innen | außen | Min. | Startwert | Max. | |||||||

| P0 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0024–0.0031 | 0.0031–0.0043 | 0.0039–0.0051 | 0.0043–0.0055 |

| – DU | WU20PH | WU20PH | 290 | 430 | 625 | IPR | – | – | 0.0031–0.0041 | 0.0034–0.0044 | |

| P1 | –V38 | WU40PH | WU25CH | 360 | 540 | 780 | IPR | 0.0024–0.0039 | 0.0031–0.0051 | 0.0039–0.0059 | 0.0043–0.0063 |

| – DU | WU20PH | WU20PH | 290 | 430 | 625 | IPR | – | – | 0.0031–0.0047 | 0.0034–0.0050 | |

| P2 | –V34 | WU40PH | WU25CH | 360 | 570 | 840 | IPR | 0.0024–0.0039 | 0.0031–0.0059 | 0.0039–0.0063 | 0.0043–0.0067 |

| – DU | WU20PH | WU20PH | 290 | 450 | 675 | IPR | – | – | 0.0031–0.0050 | 0.0034–0.0054 | |

| P3 | –V34 | WU40PH | WPK10CH | 360 | 600 | 930 | IPR | 0.0031–0.0059 | 0.0039–0.0063 | 0.0043–0.0071 | 0.0047–0.0079 |

| – DU | WU20PH | WU20PH | 290 | 480 | 745 | IPR | – | – | 0.0034–0.0067 | 0.0037–0.0063 | |

| P4 | –V34 | WU40PH | WPK10CH | 360 | 570 | 930 | IPR | 0.0031–0.0059 | 0.0039–0.0063 | 0.0043–0.0071 | 0.0047–0.0079 |

| – DU | WU20PH | WU20PH | 290 | 450 | 745 | IPR | – | – | 0.0034–0.0067 | 0.0037–0.0063 | |

| P5 | –V36 | WU40PH | WU25CH | 360 | 540 | 750 | IPR | 0.0024–0.0039 | 0.0031–0.0055 | 0.0039–0.0059 | 0.0043–0.0063 |

| – DU | WU20PH | WU20PH | 290 | 430 | 600 | IPR | – | – | 0.0031–0.0047 | 0.0034–0.0050 | |

| P6 | -V36 | WU40PH | WU25CH | 360 | 480 | 630 | IPR | 0.0024–0.0039 | 0.0031–0.0055 | 0.0039–0.0059 | 0.0043–0.0063 |

| -V36 | WU40PH | WU25CH | 290 | 385 | 500 | IPR | - | - | 0.0031-0.0047 | 0.0034-0.0050 | |

| M1 | -V38 | WU40PH | WU40PH | 360 | 480 | 720 | IPR | 0.0024–0.0047 | 0.0028–0.0051 | 0.0031–0.0059 | 0.0039–0.0063 |

| - DU | WU20PH | WU20PH | 290 | 385 | 575 | IPR | - | - | 0.0025-0.0047 | 0.0031-0.0050 | |

| M2 | –V38 | WU40PH | WU40PH | 330 | 420 | 630 | IPR | 0.0024–0.0047 | 0.0028–0.0051 | 0.0031–0.0059 | 0.0039–0.0063 |

| – DU | WU20PH | WU20PH | 265 | 340 | 500 | IPR | – | – | 0.0025–0.0047 | 0.0031–0.0050 | |

| M3 | -V36 | WU40PH | WU40PH | 300 | 360 | 600 | IPR | 0.0024–0.0047 | 0.0028–0.0051 | 0.0031–0.0059 | 0.0039–0.0063 |

| - DU | WU20PH | WU20PH | 240 | 290 | 480 | IPR | - | - | 0.0025-0.0047 | 0.0031-0.0050 | |

| K1 | -V34 | WU25CH | WPK10CH | 360 | 600 | 840 | IPR | 0.0031–0.0055 | 0.0031–0.0063 | 0.0039–0.0071 | 0.0047–0.0094 |

| - DU | WU20PH | WU20PH | 290 | 480 | 675 | IPR | - | - | 0.0031-0.0057 | 0.0038-0.0075 | |

| K2 | –V34 | WU40PH | WPK10CH | 300 | 540 | 780 | IPR | 0.0031–0.0055 | 0.0031–0.0063 | 0.0039–0.0071 | 0.0047–0.0094 |

| – DU | WU20PH | WU20PH | 240 | 430 | 625 | IPR | – | – | 0.0031–0.0057 | 0.0038–0.0075 | |

| K3 | -V34 | WU40PH | WPK10CH | 300 | 510 | 720 | IPR | 0.0031–0.0055 | 0.0031–0.0063 | 0.0039–0.0071 | 0.0047–0.0094 |

| - DU | WU20PH | WU20PH | 240 | 400 | 575 | IPR | - | - | 0.0031-0.0057 | 0.0038-0.0075 | |

| N1 | -V36 | WN10PH | WN10PH | 750 | 1050 | 1500 | IPR | 0.0024–0.0039 | 0.0031–0.0055 | 0.0039–0.0059 | 0.0043–0.0063 |

| N2 | –V36 | WN10PH | WN10PH | 450 | 900 | 1350 | IPR | 0.0024–0.0039 | 0.0031–0.0055 | 0.0039–0.0059 | 0.0043–0.0063 |

| N3 | -V36 | WN10PH | WN10PH | 240 | 360 | 450 | IPR | 0.0024–0.0039 | 0.0028–0.0043 | 0.0031–0.0047 | 0.0039–0.0055 |

| S3 | -V38 | WU40PH | WU40PH | 60 | 90 | 135 | IPR | 0.0031–0.0047 | 0.0031–0.0051 | 0.0039–0.0059 | 0.0047–0.0075 |

| - DU | WU20PH | WU20PH | 50 | 70 | 100 | IPR | - | - | 0.0031-0.0047 | 0.0038-0.006 | |

| S4 | –V38 | WU40PH | WU40PH | 105 | 120 | 195 | IPR | 0.0031–0.0047 | 0.0031–0.0051 | 0.0039–0.0059 | 0.0047–0.0075 |

| – DU | WU20PH | WU20PH | 85 | 95 | 150 | IPR | – | – | 0.0031–0.0047 | 0.0038–0.006 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use