Produkt ähnlich wie:

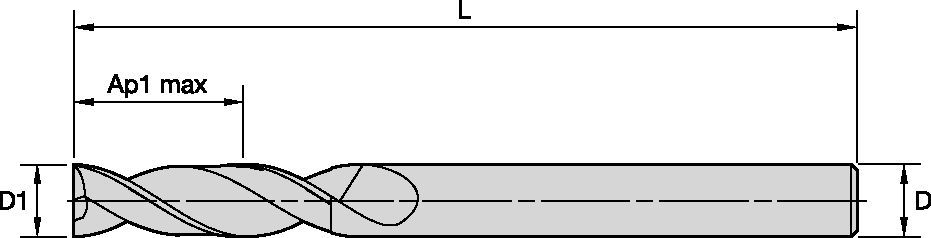

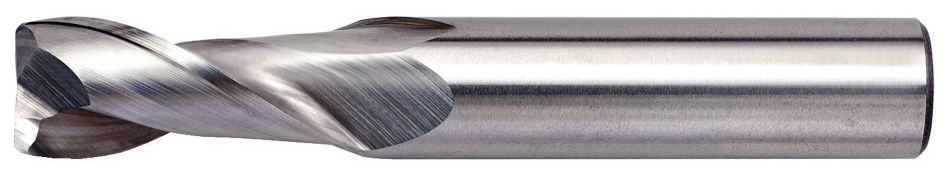

ALUFLASH • Series 2A19 • Square End • 2 Flute • Long Length • Cylindrical Shank • Inch

ALUFLASH™ Series 2A19 • Square End • 2 Flute • Long Length • Cylindrical Shank • Inch

Material Nummer6853383

ISO Katalog Nummer2A19E07013SZTANSI Katalog Nummer2A19E07013SZT

- N NE-Metalle

Trochoidal Milling

Drilling

Spiralförmiges Interpolieren

Tauchfräsen

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Ebene Stirnfläche

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 6853383 |

| ISO Katalog Nummer | 2A19E07013SZT |

| ANSI Katalog Nummer | 2A19E07013SZT |

| Sorte | UNCOATED |

| Aufnahmeart Maschinenseite | Straight-Cylindrical |

| [D1] Effektiver Schneidendurchmesser | 6.35 mm |

| [D1] Effektiver Schneidendurchmesser | 0.25 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 6.35 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.25 in |

| [AP1MAX] 1. maximale Schnitttiefe | 19.05 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 0.75 in |

| [L] Gesamtlänge | 63.5 mm |

| [L] Gesamtlänge | 2.5 in |

| [Z] Anzahl der Spannuten | 2 |

Werkstoffe

- NE-Metalle

Uses and application

Trochoidal Milling

Drilling

Spiralförmiges Interpolieren

Tauchfräsen

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Ebene Stirnfläche

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Features and benefits

- Covers a broad range of applications including helical interpolation, ramping and plunging

- Designed for use on a large variety of workpiece materials

- Delivers high tool stability through several unique features including twisted end face, parabolic core, non-linear gash profile

- Four asymmetrical divided flutes and a variable helix help reduce vibrations

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Anwendungsdaten

| Werkstoffgruppe | Helical Interpolation / Ramping 0° - 15° |  |  |  | ||||||||||||||

| UNBESCHICHTET | Empfohlener Vorschub pro Umdrehung | |||||||||||||||||

| Schnittgeschwindigkeit | Durchmesser | |||||||||||||||||

| Min. | Startwert | Max. | Fraction | 1/8 | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 9/16 | 5/8 | 23/32 | 3/4 | 1 | |||

| Max Depth | Min. | Startwert | Max. | Decimals | .180-.180 | .180-.297 | .216-.356 | .288-.475 | .359-.594 | .431-.713 | .575-.950 | .633-1.047 | .719-1.188 | .814-1.346 | .863-1.425 | 1.150-1.900 | ||

| N | 1 | 1.25 x D1 | 1500 | 1800 | 6000 | IPT | .0009 | .0017 | .0022 | .0026 | .0035 | .0043 | .0052 | .0060 | .0069 | .0078 | .0087 | .0108 |

| 2 | 1.25 x D1 | 1500 | 1800 | 4500 | IPT | .0008 | .0016 | .0019 | .0023 | .0031 | .0039 | .0047 | .0054 | .0062 | .0070 | .0078 | .0097 | |

| 3 | 1.25 x D1 | 1500 | 1800 | 4500 | IPT | .0006 | .0012 | .0015 | .0018 | .0024 | .0030 | .0036 | .0042 | .0048 | .0054 | .0061 | .0076 | |

| 4 | 1.25 x D1 | 1200 | 1350 | 2250 | IPT | .0006 | .0012 | .0015 | .0018 | .0024 | .0030 | .0036 | .0042 | .0048 | .0054 | .0061 | .0076 | |

| 5 | 1.25 x D1 | 750 | 1200 | 3000 | IPT | .0008 | .0016 | .0020 | .0023 | .0031 | .0039 | .0047 | .0054 | .0062 | .0070 | .0078 | .0097 | |

| Werkstoffgruppe | Helical Interpolation / Ramping 15° - 30° |  |  |  | ||||||||||||||

| UNBESCHICHTET | Empfohlener Vorschub pro Umdrehung | |||||||||||||||||

| Schnittgeschwindigkeit | Durchmesser | |||||||||||||||||

| Min. | Startwert | Max. | Fraction | 1/8 | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 9/16 | 5/8 | 23/32 | 3/4 | 1 | |||

| Max Depth | Min. | Startwert | Max. | Decimals | .180-.180 | .180-.297 | .216-.356 | .288-.475 | .359-.594 | .431-.713 | .575-.950 | .633-1.047 | .719-1.188 | .814-1.346 | .863-1.425 | 1.150-1.900 | ||

| N | 1 | 1.25 x D1 | 1500 | 1800 | 4800 | IPT | .0006 | .0013 | .0016 | .0019 | .0026 | .0032 | .0039 | .0045 | .0052 | .0058 | .0065 | .0081 |

| 2 | 1.25 x D1 | 1500 | 1800 | 3600 | IPT | .0006 | .0012 | .0014 | .0018 | .0023 | .0029 | .0035 | .0041 | .0047 | .0053 | .0058 | .0073 | |

| 3 | 1.25 x D1 | 1500 | 1800 | 3600 | IPT | .0005 | .0009 | .0011 | .0014 | .0018 | .0023 | .0027 | .0032 | .0036 | .0041 | .0045 | .0057 | |

| 4 | 1.25 x D1 | 1200 | 1350 | 1800 | IPT | .0005 | .0009 | .0011 | .0014 | .0018 | .0023 | .0027 | .0032 | .0036 | .0041 | .0045 | .0057 | |

| 5 | 1.25 x D1 | 750 | 1200 | 2400 | IPT | .0006 | .0012 | .0015 | .0018 | .0023 | .0029 | .0035 | .0041 | .0047 | .0053 | .0058 | .0073 | |

| Werkstoffgruppe | Helical Interpolation / Ramping 30° - 45° |  |  |  | ||||||||||||||

| UNBESCHICHTET | Empfohlener Vorschub pro Umdrehung | |||||||||||||||||

| Schnittgeschwindigkeit | Durchmesser | |||||||||||||||||

| Min. | Startwert | Max. | Fraction | 1/8 | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 9/16 | 5/8 | 23/32 | 3/4 | 1 | |||

| Max Depth | Min. | Startwert | Max. | Decimals | .180-.180 | .180-.297 | .216-.356 | .288-.475 | .359-.594 | .431-.713 | .575-.950 | .633-1.047 | .719-1.188 | .814-1.346 | .863-1.425 | 1.150-1.900 | ||

| N | 1 | 1.25 x D1 | 1260 | 1500 | 2400 | IPT | .0005 | .0010 | .0013 | .0016 | .0021 | .0026 | .0031 | .0036 | .0042 | .0047 | .0052 | .0065 |

| 2 | 1.25 x D1 | 1260 | 1500 | 2400 | IPT | .0005 | .0009 | .0011 | .0014 | .0019 | .0023 | .0028 | .0033 | .0037 | .0042 | .0047 | .0058 | |

| 3 | 1.25 x D1 | 1260 | 1500 | 2400 | IPT | .0004 | .0007 | .0009 | .0011 | .0015 | .0018 | .0022 | .0025 | .0029 | .0033 | .0036 | .0045 | |

| 4 | 1.25 x D1 | 1020 | 1140 | 1350 | IPT | .0004 | .0007 | .0009 | .0011 | .0015 | .0018 | .0022 | .0025 | .0029 | .0033 | .0036 | .0045 | |

| 5 | 1.25 x D1 | 630 | 1020 | 1800 | IPT | .0005 | .0009 | .0012 | .0014 | .0019 | .0023 | .0028 | .0033 | .0037 | .0042 | .0047 | .0058 | |

| Werkstoffgruppe |  |  |  | |||||||||||||||||

| Tauchfräsen | UNBESCHICHTET | Empfohlener Vorschub pro Umdrehung | ||||||||||||||||||

| Schnittgeschwindigkeit | D1 | |||||||||||||||||||

| Max Depth | Applicable | Coolant | Min. | Startwert | Max. | Fraction | 1/8 | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 9/16 | 5/8 | 23/32 | 3/4 | 1 | ||

| N | 1 | 1.5 x D | Required | 360 | 780 | 1200 | IPR | .0031 | .0047 | .0053 | .0059 | .0063 | .0079 | .0087 | .0093 | .0098 | .0104 | .0110 | .0118 | |

| 2 | 1.5 x D | Required | 360 | 750 | 840 | IPR | .0031 | .0047 | .0053 | .0059 | .0063 | .0079 | .0087 | .0093 | .0098 | .0104 | .0110 | .0118 | ||

| 3 | 1.5 x D | Required | 300 | 600 | 780 | IPR | .0031 | .0047 | .0053 | .0059 | .0063 | .0079 | .0087 | .0093 | .0098 | .0104 | .0110 | .0118 | ||

| 4 | 1 x D | Required | 180 | 450 | 780 | IPR | .0024 | .0031 | .0039 | .0047 | .0055 | .0063 | .0079 | .0083 | .0087 | .0093 | .0098 | .0110 | ||

| 5 | 1.5 x D | Required | 180 | 600 | 1200 | IPR | .0031 | .0047 | .0053 | .0059 | .0063 | .0079 | .0087 | .0093 | .0098 | .0104 | .0110 | .0118 | ||

| Werkstoffgruppe |  |  |  | |||||||||||||||||

| Tauchfräsen | UNBESCHICHTET | Empfohlener Vorschub pro Umdrehung | ||||||||||||||||||

| Schnittgeschwindigkeit | D1 | |||||||||||||||||||

| Max Depth | Applicable | Coolant | Min. | Startwert | Max. | Fraction | 1/8 | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 9/16 | 5/8 | 23/32 | 3/4 | 1 | ||

| N | 1 | 1,5 x D | Required | 360 | 780 | 1200 | IPR | .0022 | .0033 | .0037 | .0041 | .0044 | .0055 | .0061 | .0065 | .0069 | .0073 | .0077 | .0083 | |

| 2 | 1,5 x D | Required | 360 | 750 | 840 | IPR | .0022 | .0033 | .0037 | .0041 | .0044 | .0055 | .0061 | .0065 | .0069 | .0073 | .0077 | .0083 | ||

| 3 | 1,5 x D | Required | 300 | 600 | 780 | IPR | .0022 | .0033 | .0037 | .0041 | .0044 | .0055 | .0061 | .0065 | .0069 | .0073 | .0077 | .0083 | ||

| 4 | 1 x D | Required | 180 | 450 | 780 | IPR | .0017 | .0022 | .0028 | .0033 | .0039 | .0044 | .0055 | .0058 | .0061 | .0065 | .0069 | .0077 | ||

| 5 | 1,5 x D | Required | 180 | 600 | 1200 | IPR | .0022 | .0033 | .0037 | .0041 | .0044 | .0055 | .0061 | .0065 | .0069 | .0073 | .0077 | .0083 | ||

| Werkstoffgruppe |  |  |  | |||||||||||||||||

| Eckfräsen (A) und Nutfräsen (B) | UNBESCHICHTET | Recommended feed per tooth (Fz = IPT) for side milling (A). For slotting (B), reduce Fz by 20%. | ||||||||||||||||||

| A | B | Schnittgeschwindigkeit | D1 | |||||||||||||||||

| ap | ae | ap | Min. | Startwert | Max. | Fraction | 1/8 | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 9/16 | 5/8 | 23/32 | 3/4 | 1 | ||

| N | 1 | Ap1 max | 0,5 x D1 | 1 x D | 1500 | 1800 | 6000 | IPT | .0009 | .0017 | .0022 | .0026 | .0035 | .0043 | .0052 | .0060 | .0069 | .0078 | .0087 | .0108 |

| 2 | Ap1 max | 0,5 x D1 | 1 x D | 1500 | 1800 | 4500 | IPT | .0008 | .0016 | .0019 | .0023 | .0031 | .0039 | .0047 | .0054 | .0062 | .0070 | .0078 | .0097 | |

| 3 | Ap1 max | 0,5 x D1 | 1 x D | 1500 | 1800 | 4500 | IPT | .0006 | .0012 | .0015 | .0018 | .0024 | .0030 | .0036 | .0042 | .0048 | .0054 | .0061 | .0076 | |

| 4 | Ap1 max | 0,5 x D1 | 1 x D | 1200 | 1350 | 2250 | IPT | .0006 | .0012 | .0015 | .0018 | .0024 | .0030 | .0036 | .0042 | .0048 | .0054 | .0061 | .0076 | |

| 5 | Ap1 max | 0,5 x D1 | 1 x D | 750 | 1200 | 3000 | IPT | .0008 | .0016 | .0020 | .0023 | .0031 | .0039 | .0047 | .0054 | .0062 | .0070 | .0078 | .0097 | |

| Werkstoffgruppe |  |  |  | |||||||||||||||||

| Eckfräsen (A) und Nutfräsen (B) | UNBESCHICHTET | Recommended feed per tooth (Fz = IPT) for side milling (A). For slotting (B), reduce Fz by 20%. | ||||||||||||||||||

| A | B | Schnittgeschwindigkeit | D1 | |||||||||||||||||

| ap | ae | ap | Min. | Startwert | Max. | Fraction | 1/8 | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 9/16 | 5/8 | 23/32 | 3/4 | 1 | ||

| N | 1 | Ap1 max | 0,5 x D1 | 1 x D1 | 1500 | 1800 | 6000 | IPT | .0009 | .0017 | .0022 | .0026 | .0035 | .0043 | .0052 | .0060 | .0069 | .0078 | .0087 | .0108 |

| 2 | Ap1 max | 0,5 x D1 | 1 x D1 | 1500 | 1800 | 4500 | IPT | .0008 | .0016 | .0019 | .0023 | .0031 | .0039 | .0047 | .0054 | .0062 | .0070 | .0078 | .0097 | |

| 3 | Ap1 max | 0,5 x D1 | 1 x D1 | 1500 | 1800 | 4500 | IPT | .0006 | .0012 | .0015 | .0018 | .0024 | .0030 | .0036 | .0042 | .0048 | .0054 | .0061 | .0076 | |

| 4 | Ap1 max | 0,5 x D1 | 1 x D1 | 1200 | 1350 | 2250 | IPT | .0006 | .0012 | .0015 | .0018 | .0024 | .0030 | .0036 | .0042 | .0048 | .0054 | .0061 | .0076 | |

| 5 | Ap1 max | 0,5 x D1 | 1 x D1 | 750 | 1200 | 3000 | IPT | .0008 | .0016 | .0020 | .0023 | .0031 | .0039 | .0047 | .0054 | .0062 | .0070 | .0078 | .0097 | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data