Produkt ähnlich wie:

Vision Plus™ • Series 7S05 • Sharp Edge • Cylindrical Shank • Inch

Series 7S05 • Vision Plus™

Material Nummer3054914

ISO Katalog NummerTM7S1508000ANSI Katalog NummerTM7S1508000

- P Stahl

- H Gehärtete Werkstoffe

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Ebene Stirnfläche

Werkzeugabmessungen: Schneidreihen: X (variabel)

Schneideckenausführung: Ebene Stirnfläche

Side Milling/Shoulder Milling: Square End

38495

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 3054914 |

| ISO Katalog Nummer | TM7S1508000 |

| ANSI Katalog Nummer | TM7S1508000 |

| Sorte | ALTIN-MT1 |

| Aufnahmeart Maschinenseite | Straight-Cylindrical |

| [Z] Anzahl der Spannuten | 4 |

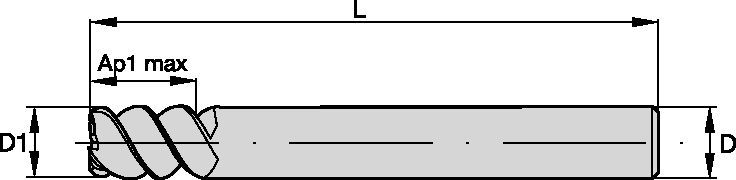

| [D1] Effektiver Schneidendurchmesser | 7.938 mm |

| [D1] Effektiver Schneidendurchmesser | 0.3125 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 7.938 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.3125 in |

| [AP1MAX] 1. maximale Schnitttiefe | 19.05 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 0.75 in |

| [L] Gesamtlänge | 101.6 mm |

| [L] Gesamtlänge | 4 in |

Werkstoffe

- Stahl

- Gehärtete Werkstoffe

Uses and application

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Ebene Stirnfläche

Werkzeugabmessungen: Schneidreihen: X (variabel)

Schneideckenausführung: Ebene Stirnfläche

Side Milling/Shoulder Milling: Square End

38495

Features and benefits

- Center cutting.

- Standard items listed. Additional styles and coatings made-to-order.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Anwendungsdaten

Series 7S05 • Vision Plus

|  |  | |||||||||||||

| Eckfräsen (A) und Nutfräsen (B) | AlTiN | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||

| A | B | Schnittgeschwindigkeit | D1 | ||||||||||||

| frac. | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||

| Werkstoffgruppe | ap | ae | ap | Min. | Max. | dec. | .2500 | .3100 | .3800 | .5000 | .6300 | .7500 | 1.000 | ||

| P | 3 | 1 x D | 0.4 x D | 1 x D | 390 | – | 520 | IPT | .0017 | .0021 | .0025 | .0032 | .0037 | .0042 | .0050 |

| 4 | 1 x D | 0.4 x D | 0.75 x D | 300 | – | 490 | IPT | .0015 | .0019 | .0022 | .0029 | .0033 | .0036 | .0043 | |

| H | 1 | 1 x D | 0.4 x D | 0.75 x D | 260 | – | 460 | IPT | .0015 | .0019 | .0022 | .0029 | .0033 | .0036 | .0043 |

| 2 | 1 x D | 0.3 x D | 0.5 x D | 230 | – | 390 | IPT | .0011 | .0014 | .0017 | .0021 | .0024 | .0027 | .0031 | |

| 3 | 1 x D | 0.15 x D | 0.3 x D | 200 | – | 300 | IPT | .0009 | .0011 | .0013 | .0017 | .0020 | .0022 | .0027 | |

| 4 | 1 x D | 0.1 x D | 0.15 x D | 160 | – | 230 | IPT | .0006 | .0008 | .0009 | .0011 | .0013 | .0015 | .0018 | |

Series 7S15 • Vision Plus

| Werkstoffgruppe |  |  |  | |||||||||||||||

| Eckfräsen (A) und Nutfräsen (B) | AlTiN-MT | TiAlN | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||||

| A | B | Schnittgeschwindigkeit | Schnittgeschwindigkeit | D1 | ||||||||||||||

| frac. | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||||||

| ap | ae | ap | Min. | Max. | Min. | Max. | dec. | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||||

| P | 3 | 2.0 x D | 0.3 x D | 0.75 x D | 390 | – | 520 | 390 | – | 520 | IPT | .0017 | .0021 | .0025 | .0032 | .0038 | .0042 | .0050 |

| 4 | 2.0 x D | 0.25 x D | 0.5 x D | 300 | – | 490 | 300 | – | 490 | IPT | .0015 | .0019 | .0022 | .0028 | .0033 | .0037 | .0042 | |

| H | 1 | 2.0 x D | 0.25 x D | 0.5 x D | 260 | – | 460 | 260 | – | 460 | IPT | .0015 | .0019 | .0022 | .0028 | .0033 | .0037 | .0042 |

| 2 | 2.0 x D | 0.2 x D | 0.4 x D | 230 | – | 390 | 230 | – | 390 | IPT | .0011 | .0014 | .0017 | .0021 | .0025 | .0027 | .0031 | |

| 3 | 2.0 x D | 0.1 x D | 0.2 x D | 200 | – | 300 | 200 | – | 300 | IPT | .0009 | .0011 | .0013 | .0017 | .0020 | .0023 | .0027 | |

| 4 | 2.0 x D | 0.05 x D | 0.05 x D | 160 | – | 230 | 160 | – | 230 | IPT | .0006 | .0008 | .0009 | .0011 | .0013 | .0015 | .0018 | |

Series 7S25 • Vision Plus

| Werkstoffgruppe |  |  |  | |||||||||||||||

| Eckfräsen (A) und Nutfräsen (B) | AlTiN-MT | TiAlN | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||||

| A | B | Schnittgeschwindigkeit | Schnittgeschwindigkeit | D1 | ||||||||||||||

| frac. | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||||||

| ap | ae | ap | Min. | Max. | Min. | Max. | dec. | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||||

| P | 3 | 3.0xD | 0.2XD | 0.5xD | 390 | – | 520 | 390 | – | 520 | IPT | .0017 | .0021 | .0025 | .0032 | .0038 | .0042 | .0050 |

| 4 | 3.0xD | 0.2XD | 0.3xD | 300 | – | 490 | 300 | – | 490 | IPT | .0015 | .0019 | .0022 | .0028 | .0033 | .0037 | .0042 | |

| H | 1 | 3.0xD | 0.2XD | 0.3xD | 260 | – | 460 | 260 | – | 460 | IPT | .0015 | .0019 | .0022 | .0028 | .0033 | .0037 | .0042 |

| 2 | 3.0xD | 0.15XD | 0.2xD | 230 | – | 390 | 230 | – | 390 | IPT | .0011 | .0014 | .0017 | .0021 | .0025 | .0027 | .0031 | |

| 3 | 3.0xD | 0.05XD | – | 200 | – | 300 | 200 | – | 300 | IPT | .0009 | .0011 | .0013 | .0017 | .0020 | .0023 | .0027 | |

| 4 | 3.0xD | 0.03XD | – | 160 | – | 230 | 160 | – | 230 | IPT | .0006 | .0008 | .0009 | .0011 | .0013 | .0015 | .0018 | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data