Produkt ähnlich wie:

M680-16 • XPHT

Wendeschneidplatten • XPHT

Material Nummer2025362

ISO Katalog NummerXPHT160412ANSI Katalog NummerXPHT333

- M Rostfreier Stahl

- K Gusseisen

- N NE-Metalle

- S Hochwarmfeste Legierungen

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

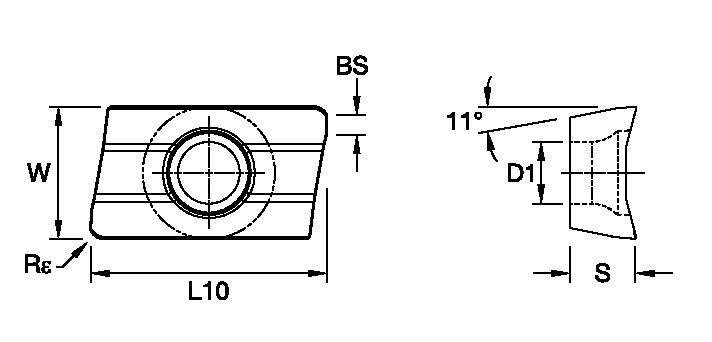

| Material Nummer | 2025362 |

| ISO Katalog Nummer | XPHT160412 |

| ANSI Katalog Nummer | XPHT333 |

| Sorte | THM |

| Schneidkanten pro Wendeschneidplatte | 2 |

| [W] Schneideinsatzbreite | 9.525 mm |

| [W] Schneideinsatzbreite | 0.375 in |

| [L10] Schneidkantenlänge der Wendeschneidplatte | 15.67 mm |

| [L10] Schneidkantenlänge der Wendeschneidplatte | 0.6169 in |

| [S] Dicke der Wendeschneidplatte | 4.763 mm |

| [S] Dicke der Wendeschneidplatte | 0.1875 in |

| [BS] Eckflächenlänge | 1.5 mm |

| [BS] Eckflächenlänge | 0.059 in |

| [Rε] Eckenradius | 1.2 mm |

| [Rε] Eckenradius | 0.047 in |

| Mittlere Spandicke [HM] | 0.16 mm |

| Mittlere Spandicke [HM] | 0.0063 in |

Werkstoffe

- Rostfreier Stahl

- Gusseisen

- NE-Metalle

- Hochwarmfeste Legierungen

Grades

THM

Unbeschichtetes Hartmetall. Außerordentlich ausgewogene Kombination aus Härte, Verschleißfestigkeit, Schneidkantenstabilität und Zähigkeit. Leichte und mittlere Bearbeitung. Für Gusseisen, alle NE-Metalle und Nichtmetalle. Einsetzbar auch bei ungünstigen Schnittbedingungen.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Feeds

Empfohlene Startwerte für Vorschübe [mm]

| Schneidkörper- Geometrie | Programmierter Vorschub pro Zahn (fz) | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| XPHT-ALP | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | XPHT-ALP |

| XPHT-GE | 0,19 | 0,47 | 0,70 | 0,14 | 0,34 | 0,50 | 0,11 | 0,26 | 0,38 | 0,09 | 0,22 | 0,33 | 0,08 | 0,20 | 0,30 | XPHT-GE |

| XPHT.. | 0,22 | 0,56 | 0,82 | 0,16 | 0,40 | 0,59 | 0,12 | 0,30 | 0,44 | 0,10 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | XPHT.. |

| XPNT.. | 0,22 | 0,56 | 0,82 | 0,16 | 0,40 | 0,59 | 0,12 | 0,30 | 0,44 | 0,10 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | XPNT.. |

| XPHT-MR | 0,23 | 0,59 | 0,92 | 0,17 | 0,43 | 0,66 | 0,13 | 0,32 | 0,50 | 0,11 | 0,28 | 0,43 | 0,10 | 0,25 | 0,40 | XPHT-MR |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Recommended Starting Feeds [IPT]

| Schneidkörper- Geometrie | Programmierter Vorschub pro Zahn (fz) | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | .005 | .014 | .022 | .003 | .010 | .016 | .003 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .010 | .F..ALP |

| .E..AL | .005 | .014 | .022 | .003 | .010 | .016 | .003 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .010 | .E..AL |

| .E..GE | .008 | .018 | .027 | .005 | .013 | .020 | .004 | .010 | .015 | .004 | .009 | .013 | .003 | .008 | .012 | .E..GE |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Speeds

Empfohlene Start-Schnittgeschwindigkeiten [m/min]

| Werkstoffgruppe | THR | THM-U | TN6501 | TN6502 | TN6510 | TN6520 | TN6525 | TN6540 | |||||||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 |

| 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 340 | 265 | 235 | 300 | 235 | 200 | |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 265 | 210 | 180 | 210 | 160 | 140 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 235 | 180 | 155 | 180 | 140 | 115 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 195 | 140 | 120 | 150 | 110 | 90 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 260 | 195 | 165 | 200 | 150 | 125 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 170 | 135 | 110 | 135 | 100 | 85 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 100 | 65 | 110 | 65 | 50 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 100 | 65 | 40 | 65 | 40 | 35 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 105 | 65 | 45 | 70 | 40 | 35 | |

| K | 1 | 150 | 135 | 120 | 190 | 170 | 150 | – | – | – | – | – | – | 400 | 290 | 215 | 375 | 265 | 190 | 230 | 205 | 185 | 185 | 170 | 150 |

| 2 | 185 | 140 | 120 | – | – | – | – | – | – | – | – | – | 350 | 235 | 170 | 325 | 210 | 160 | 180 | 160 | 150 | 145 | 130 | 115 | |

| 3 | 105 | 75 | 50 | – | – | – | – | – | – | – | – | – | 280 | 215 | 165 | 250 | 190 | 135 | 150 | 135 | 120 | 130 | 120 | 105 | |

| N | 1 | 900 | 600 | 500 | 2000 | 1200 | 1000 | 2000 | 1200 | 1000 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 685 | 465 | 385 | 1365 | 815 | 665 | 1365 | 815 | 665 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 450 | 280 | 200 | 800 | 500 | 400 | 800 | 500 | 400 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 35 | 25 | 20 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 30 | 25 |

| 2 | 25 | 20 | 15 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 20 | 15 | 10 | |

| 3 | 50 | 40 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 35 | 25 | |

| 4 | 35 | 25 | 18 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 25 | 20 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Werkstoffgruppe | TTM08 | WK15PM | WK15PM | WP35CM | WU20PM | TTI25 | THM | WK15CM | WP40PM | WS30PM | |||||||||||||||||||||

| P | 0 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 360 | 300 | 250 | – | – | – | – | – | – | 295 | 260 | 245 | – | – | – |

| 1 | 230 | 200 | 190 | – | – | – | – | – | – | 455 | 395 | 370 | 330 | 290 | 270 | 360 | 300 | 250 | – | – | – | – | – | – | 295 | 260 | 245 | – | – | – | |

| 2 | 195 | 170 | 140 | – | – | – | – | – | – | 280 | 255 | 230 | 275 | 250 | 200 | 260 | 210 | 180 | – | – | – | – | – | – | 250 | 215 | 180 | – | – | – | |

| 3 | 180 | 150 | 125 | – | – | – | – | – | – | 255 | 230 | 205 | 255 | 220 | 175 | 260 | 210 | 180 | – | – | – | – | – | – | 230 | 195 | 160 | – | – | – | |

| 4 | 160 | 130 | 105 | – | – | – | – | – | – | 190 | 175 | 160 | 225 | 190 | 150 | 220 | 180 | 150 | – | – | – | – | – | – | 205 | 170 | 135 | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | 260 | 230 | 210 | 185 | 175 | 150 | 265 | 195 | 165 | – | – | – | – | – | – | 170 | 155 | 135 | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | 160 | 135 | 110 | 165 | 130 | 100 | 120 | 90 | 75 | – | – | – | – | – | – | 150 | 115 | 90 | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | 205 | 185 | 155 | 205 | 180 | 165 | 400 | 260 | 180 | – | – | – | – | – | – | 195 | 170 | 155 | 225 | 200 | 185 |

| 2 | – | – | – | – | – | – | – | – | – | 185 | 160 | 140 | 185 | 160 | 130 | 270 | 170 | 120 | – | – | – | – | – | – | 175 | 150 | 125 | 205 | 180 | 145 | |

| 3 | – | – | – | – | – | – | – | – | – | 145 | 130 | 115 | 140 | 120 | 95 | 265 | 175 | 120 | – | – | – | – | – | – | 130 | 115 | 90 | 155 | 135 | 105 | |

| K | 1 | – | – | – | 400 | 290 | 215 | 360 | 290 | 245 | 295 | 265 | 240 | 250 | 220 | 185 | 185 | 155 | 130 | – | – | – | 420 | 385 | 340 | – | – | – | – | – | – |

| 2 | – | – | – | 350 | 235 | 170 | 280 | 230 | 195 | 235 | 210 | 190 | 200 | 180 | 150 | 150 | 120 | 105 | – | – | – | 335 | 295 | 275 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 215 | 165 | 210 | 175 | 140 | 195 | 175 | 160 | 180 | 150 | 120 | 120 | 105 | 85 | – | – | – | 280 | 250 | 230 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | 795 | 695 | 600 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 550 | 470 | 400 | – | – | – | 795 | 695 | 600 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 400 | 350 | 300 | – | – | – | 560 | 485 | 420 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | |

| 4 | – | – | – | – | – | – | – | – | – | 66 | 50 | 33 | 70 | 50 | 35 | – | – | – | – | – | – | – | – | – | 65 | 50 | 35 | 85 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 110 | 80 | 70 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | THM | THM-U | THR | TN6501 | TN6502 | TN6510 | TN6520 | TN6525 | |||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1345 | 1050 | 920 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1050 | 820 | 705 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 920 | 705 | 605 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 770 | 560 | 475 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1015 | 770 | 640 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 670 | 525 | 425 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 625 | 395 | 260 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 395 | 260 | 165 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 410 | 260 | 180 | |

| K | 1 | 390 | 295 | 245 | 620 | 555 | 490 | 490 | 440 | 390 | – | – | – | – | – | – | 1575 | 1150 | 835 | 1475 | 1050 | 755 | – | – | – |

| 2 | 410 | 325 | 225 | – | – | – | 605 | 455 | 390 | – | – | – | – | – | – | 1380 | 920 | 670 | 1280 | 820 | 625 | – | – | – | |

| 3 | 425 | 310 | 195 | – | – | – | 340 | 245 | 160 | – | – | – | – | – | – | 1100 | 855 | 655 | 985 | 740 | 525 | – | – | – | |

| N | 1 | 2950 | 1965 | 1640 | 6560 | 3935 | 3280 | 2950 | 1965 | 1640 | 6560 | 3935 | 3280 | 5245 | 3115 | 2620 | – | – | – | – | – | – | – | – | – |

| 2 | 2245 | 1525 | 1260 | 4475 | 2670 | 2180 | 2245 | 1525 | 1260 | 4475 | 2670 | 2180 | 3605 | 2180 | 1800 | – | – | – | – | – | – | – | – | – | |

| 3 | 1475 | 915 | 655 | 2620 | 1640 | 1310 | 1475 | 915 | 655 | 2620 | 1640 | 1310 | 2130 | 1310 | 980 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 110 | 80 | 65 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 80 | 65 | 45 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 160 | 130 | 95 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 110 | 80 | 55 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| Werkstoffgruppe | TN6540 | TTI25 | TTM08 | WK15CM | WK15PM | WP35CM | WP40PM | WS30PM | WU20PM | |||||||||||||||||||

| P | 1 | 1180 | 920 | 785 | 1180 | 985 | 820 | 750 | 655 | 620 | – | – | – | – | – | – | 1490 | 1295 | 1210 | 970 | 855 | 805 | 1215 | 1050 | 985 | 1080 | 950 | 885 |

| 2 | 820 | 625 | 540 | 855 | 690 | 590 | 635 | 555 | 455 | – | – | – | – | – | – | 915 | 835 | 750 | 820 | 705 | 590 | 1000 | 885 | 720 | 900 | 820 | 655 | |

| 3 | 705 | 540 | 460 | 855 | 690 | 590 | 590 | 490 | 410 | – | – | – | – | – | – | 835 | 750 | 670 | 755 | 640 | 525 | 935 | 785 | 640 | 835 | 720 | 570 | |

| 4 | 590 | 425 | 360 | 720 | 590 | 490 | 520 | 425 | 340 | – | – | – | – | – | – | 620 | 570 | 520 | 670 | 560 | 445 | 820 | 670 | 540 | 735 | 620 | 490 | |

| 5 | 785 | 590 | 490 | 870 | 640 | 540 | – | – | – | – | – | – | – | – | – | 850 | 750 | 685 | 560 | 510 | 445 | 670 | 625 | 540 | 605 | 570 | 490 | |

| 6 | 525 | 395 | 330 | 395 | 295 | 245 | – | – | – | – | – | – | – | – | – | 520 | 440 | 360 | 490 | 375 | 295 | 605 | 460 | 360 | 540 | 425 | 325 | |

| M | 1 | 425 | 260 | 195 | 1310 | 855 | 590 | – | – | – | – | – | – | – | – | – | 670 | 605 | 505 | 640 | 560 | 510 | 740 | 655 | 605 | 670 | 590 | 540 |

| 2 | 260 | 165 | 130 | 885 | 560 | 395 | – | – | – | – | – | – | – | – | – | 605 | 520 | 455 | 575 | 490 | 410 | 670 | 590 | 475 | 605 | 520 | 425 | |

| 3 | 280 | 165 | 130 | 870 | 575 | 395 | – | – | – | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 510 | 445 | 345 | 455 | 390 | 310 | |

| K | 1 | – | – | – | 605 | 510 | 425 | – | – | – | 1380 | 1265 | 1115 | 1310 | 950 | 705 | 965 | 865 | 785 | – | – | – | 835 | 740 | 640 | 820 | 720 | 605 |

| 2 | – | – | – | 490 | 395 | 345 | – | – | – | 1100 | 970 | 900 | 1145 | 770 | 555 | 770 | 685 | 620 | – | – | – | 655 | 590 | 540 | 655 | 590 | 490 | |

| 3 | – | – | – | 395 | 345 | 280 | – | – | – | 920 | 820 | 755 | 915 | 800 | 540 | 635 | 570 | 520 | – | – | – | 540 | 490 | 445 | 590 | 490 | 390 | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1800 | 1540 | 1310 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1310 | 1145 | 980 | |

| S | 1 | 150 | 115 | 100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 130 | 110 | 80 |

| 2 | 80 | 65 | 35 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 130 | 110 | 80 | |

| 3 | 230 | 130 | 100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 180 | 150 | 100 | 160 | 130 | 80 | |

| 4 | 195 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 215 | 160 | 105 | 215 | 165 | 115 | 280 | 195 | 130 | 225 | 160 | 110 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 445 | 330 | 245 | 360 | 260 | 225 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data