Product Similar To:

TT GP HPV-KM4X

Shrink Fit Toolholders General Purpose (GP)

Material Number4156046

ISO Catalog IDKM4X100HPVTT06085MANSI Catalog IDKM4X100HPVTT06085M

Axial Adjustment - End

Balanced-by-Design

Accuracy - 3μm or Less

Shank - Cylindrical Plain ≤h6

Shank - Cylindrical Weldon® ≤h6

Shank - Cylindrical Whistle Notch ≤h6

Balance - G 2.5@15,000 min-1

Balance - G 2.5@15,000 min-1

Coolant - Through Coolant 100 bar (1500 psi) Maximum

Coolant - Through Coolant 100 bar (1500 psi) Maximum

Shank: KM4X™

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 4156046 |

| ISO Catalog ID | KM4X100HPVTT06085M |

| ANSI Catalog ID | KM4X100HPVTT06085M |

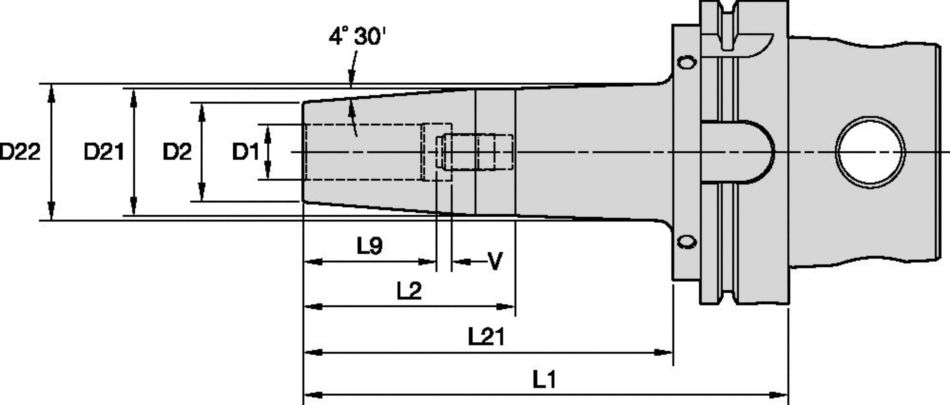

| [D1] Adapter / Shank / Bore Diameter | 6 mm |

| [D1] Adapter / Shank / Bore Diameter | .236 in |

| [D2] Body Diameter 1 Workpiece Side | 21 mm |

| [D2] Body Diameter 1 Workpiece Side | .827 in |

| [D21] Body Diameter 2 Workpiece Side | 26.9 mm |

| [D21] Body Diameter 2 Workpiece Side | 1.059 in |

| [L1] Gage Length | 85 mm |

| [L1] Gage Length | 3.346 in |

| [L2] Usable Length | 56.05 mm |

| [L2] Usable Length | 2.207 in |

| [L9] Clamping Length | 26 mm |

| [L9] Clamping Hole Length | 1.02 in |

| [V] Adjustment Range | 10 mm |

| [V] Adjustment Range | .4 in |

| Stop Screw ID Drive Size | 2.5 mm |

| Weight Kilograms | 2.47 |

Uses and application

Axial Adjustment - End

Balanced-by-Design

Accuracy - 3μm or Less

Shank - Cylindrical Plain ≤h6

Shank - Cylindrical Weldon® ≤h6

Shank - Cylindrical Whistle Notch ≤h6

Balance - G 2.5@15,000 min-1

Balance - G 2.5@15,000 min-1

Coolant - Through Coolant 100 bar (1500 psi) Maximum

Coolant - Through Coolant 100 bar (1500 psi) Maximum

Shank: KM4X™

Features and benefits

- Balanceable — fine tune with optional M6 set screws.

- Suitable for carbide and HSS cutting tools.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use