Product Similar To:

M94 • Weldon® Shank

Weldon® Shanks

Material Number2022619

ISO Catalog ID12290900800ANSI Catalog ID12290900800

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

Slotting: Side

Shank - Cylindrical Weldon 2 Flat

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

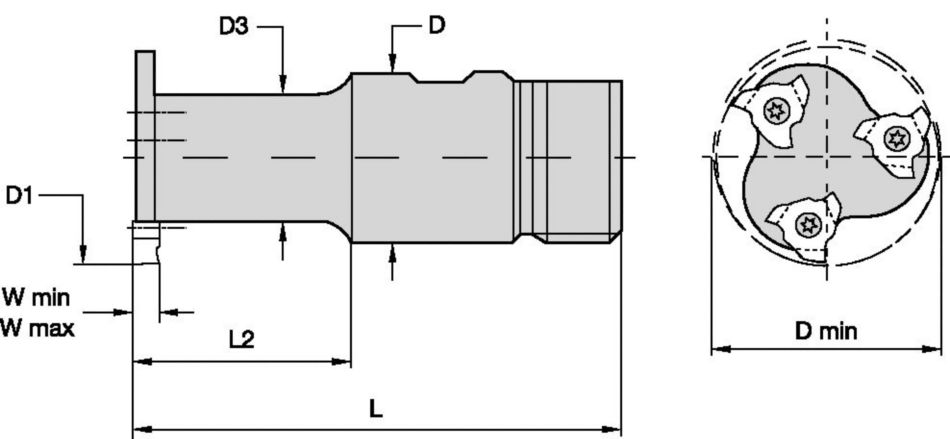

| Material Number | 2022619 |

| ISO Catalog ID | 12290900800 |

| ANSI Catalog ID | 12290900800 |

| Grade | W |

| [D1] Effective Cutting Diameter | 25 mm |

| [D1] Effective Cutting Diameter | .984 in |

| [D] Adapter / Shank / Bore Diameter | 25 mm |

| [D] Adapter / Shank / Bore Diameter | .9843 in |

| [D3] Neck Diameter | 20.5 mm |

| [D3] Neck Diameter | .807 in |

| [DM] Minimum Bore Diameter | 34 mm |

| MIL_D_MIN_I | 1.339 in |

| [L] Overall Length | 100 mm |

| [L] Overall Length | 3.937 in |

| [L2] Head Length | 44 mm |

| [L2] Head Length | 1.732 in |

| [WM] Minimum Groove Width | 1.93 mm |

| MIL_CTLG_INS_W_MIN_I | .076 in |

| [WMAX] Maximum Groove Width | 2.73 mm |

| MIL_CTLG_INS_W_MAX_I | .1075 in |

| Number of Inserts | 3 |

| Gage Insert | TCAX1103ZZ. |

| Coolant Supply | N |

| Weight Kilograms | 0.4 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

Uses and application

Slotting: Side

Shank - Cylindrical Weldon 2 Flat

Features and benefits

- Three cutting edges per insert.

- Tangential mounted inserts.

- Shallow grooving and slotting.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| P3–P4 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| P5–P6 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| M1–M2 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| M3 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| K1–K2 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 | TCAX/TNAX | TTM/TTM08 |

| K3 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| N1–N2 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| N3 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| S1–S2 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| S3 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| S4 | TCAX/TNAX | THM | TCAX/TNAX | THM | TCAX/TNAX | THM |

| H1 | – | – | – | – | – | – |

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| TCAX/TNAX | 0,12 | 0,29 | 0,45 | 0,08 | 0,21 | 0,33 | 0,06 | 0,16 | 0,25 | 0,06 | 0,14 | 0,21 | 0,05 | 0,13 | 0,20 | TCAX/TNAX |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | THM | TTM/TTM08 | |||||

| P | 1 | – | – | – | 560 | 490 | 460 |

| 2 | – | – | – | 345 | 280 | 245 | |

| 3 | – | – | – | 345 | 280 | 245 | |

| 4 | – | – | – | 280 | 195 | 180 | |

| 5 | – | – | – | 360 | 280 | 260 | |

| 6 | – | – | – | 165 | 130 | 115 | |

| M | 1 | – | – | – | 330 | 195 | 130 |

| 2 | – | – | – | 195 | 115 | 80 | |

| 3 | – | – | – | 215 | 130 | 100 | |

| K | 1 | 395 | 295 | 245 | – | – | – |

| 2 | 410 | 330 | 230 | – | – | – | |

| 3 | 425 | 310 | 195 | – | – | – | |

| N | 1 | 2950 | 1970 | 1640 | – | – | – |

| 2 | 2245 | 1525 | 1265 | – | – | – | |

| 3 | 1475 | 920 | 655 | – | – | – | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use